Operation

309032L 3

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1. Close the supply pump’s bleed-type master air valve

(required in pneumatic systems).

2. Open the dispensing valve until pressure is fully

relieved.

3. Open the fluid drain valve at the pump fluid outlet.

Leave the drain valve open until you are ready to

use the system again.

NOTE: If you suspect the dispensing valve, extension,

or grease fitting coupler is clogged, or the pressure has

not been fully relieved after following the previous steps,

using a rag VERY SLOWLY loosen the coupler or hose

end coupling and allow pressure to be relieved gradu-

ally, then loosen the part completely then clear the clog.

Adjustment

The dispense valve provides positive control of high

pressure lubricants. When supplied with air the pump

will start when the valve is triggered and still stall against

pressure when the trigger is released.

1. Relieve the pressure, see Pressure Relief Proce-

dure.

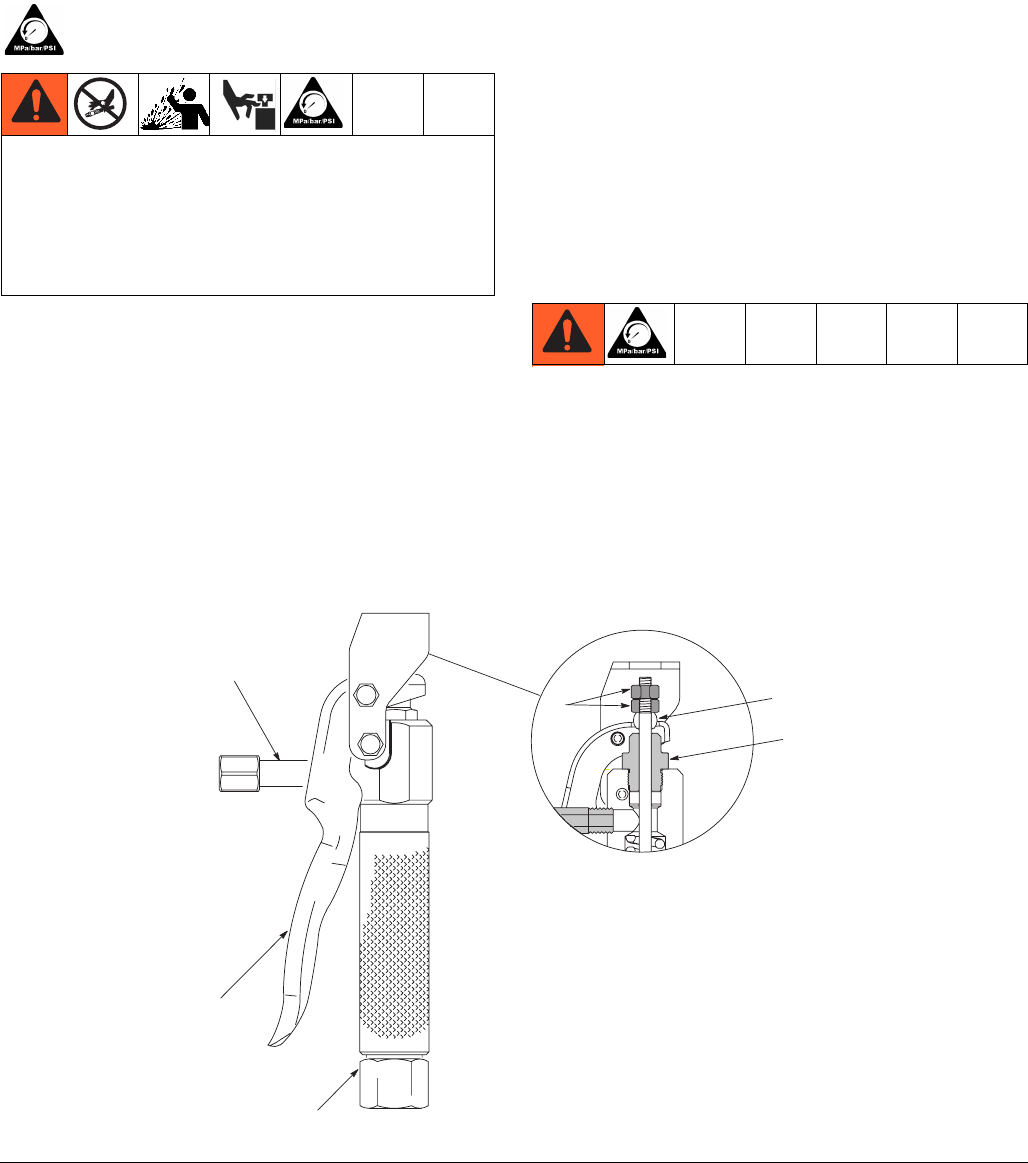

2. To adjust the clearance, loosen the top nut (5, Fig 1)

and turn the bottom nut (5) in or out as needed. To

increase grease flow turn bottom nut in. To reduce

grease flow turn bottom nut out. Hold the bottom nut

in place and securely tight the top nut.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

FIG. 1

5

11

7

Torque 90 – 110 ft. lbs.

Yoke

Rod Guide