Installation

6 313034A

Installation

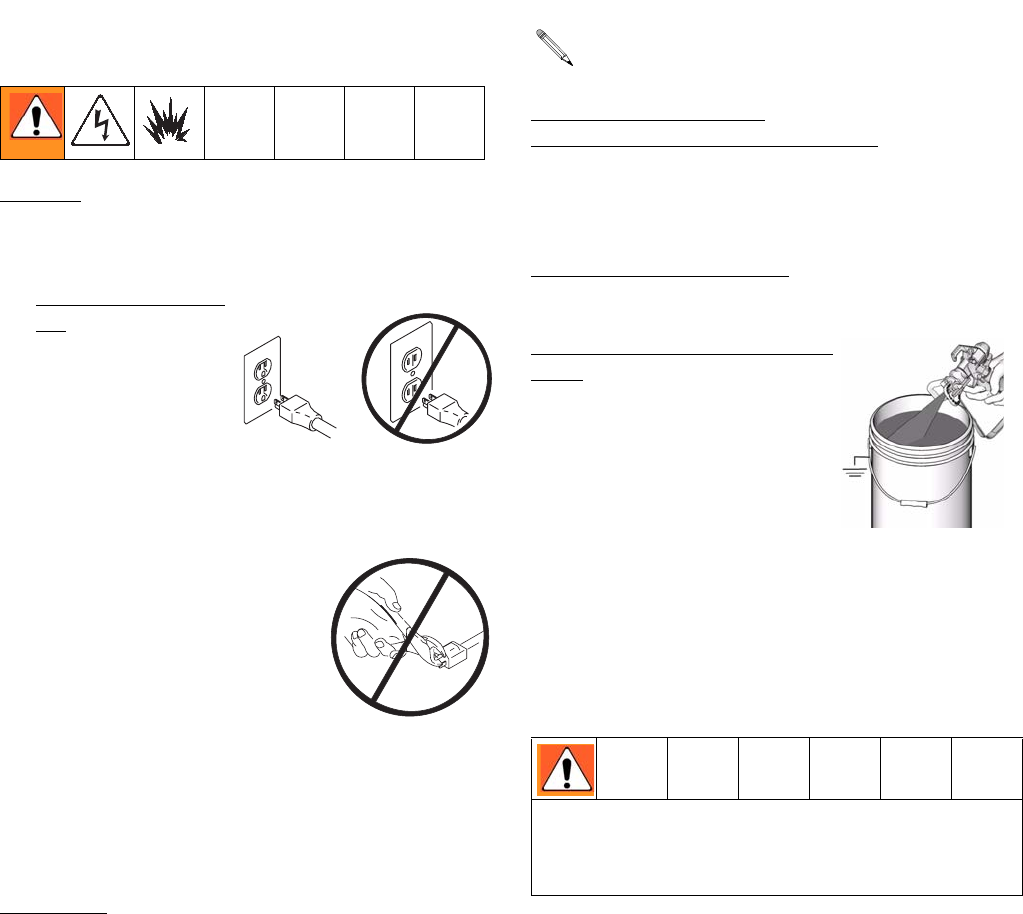

Grounding and Electric

Requirements

Sprayer must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for electrical current due to static build

up or in the event of a short circuit.

• The 120 Vac spray-

ers require a 120

Vac, 60 Hz, 15A cir-

cuit with a ground-

ing receptacle.

• Never use an outlet

that is not grounded

or an adapter.

• Do not use the sprayer if the

electrical cord has a dam-

aged ground prong.

• Only use an extension cord

with an undamaged 3-prong

plug.

Recommended extension cords for use with

this sprayer:

• 50 ft (15.0 m) 14 AWG (2.1 mm

2

)

• 100 ft (30.0 m) 12 AWG (3.3 mm

2

)

Spray gun

: ground through connection to a prop-

erly grounded fluid hose and pump.

Fluid supply container

: follow local code.

Solvent pails used when flushing

: follow local

code. Use only conductive metal pails, placed on a

grounded surface such as concrete. Do not place

the pail on a nonconductive surface, such as paper

or cardboard, which interrupts grounding continuity.

Grounding the metal pail

: connect a ground wire

to the pail by clamping one end to pail and other

end to ground such as a water pipe.

Maintaining grounding conti-

nuity when flushing or reliev-

ing pressure: hold metal part

of the spray gun firmly to the

side of a grounded metal pail,

then trigger the gun.

Thermal Overload

Motor has a thermal overload switch to shut itself

down if overheated. If unit overheats, allow approx-

imately 45 minutes for unit to cool. Once cool,

switch will close and unit will restart.

ti5573a

ti5572a

Smaller gauge or longer extension cords may

reduce sprayer performance.

To reduce risk of injury from motor starting unex-

pectedly when it cools, always turn power switch

OFF if motor shuts down.

ti9207a