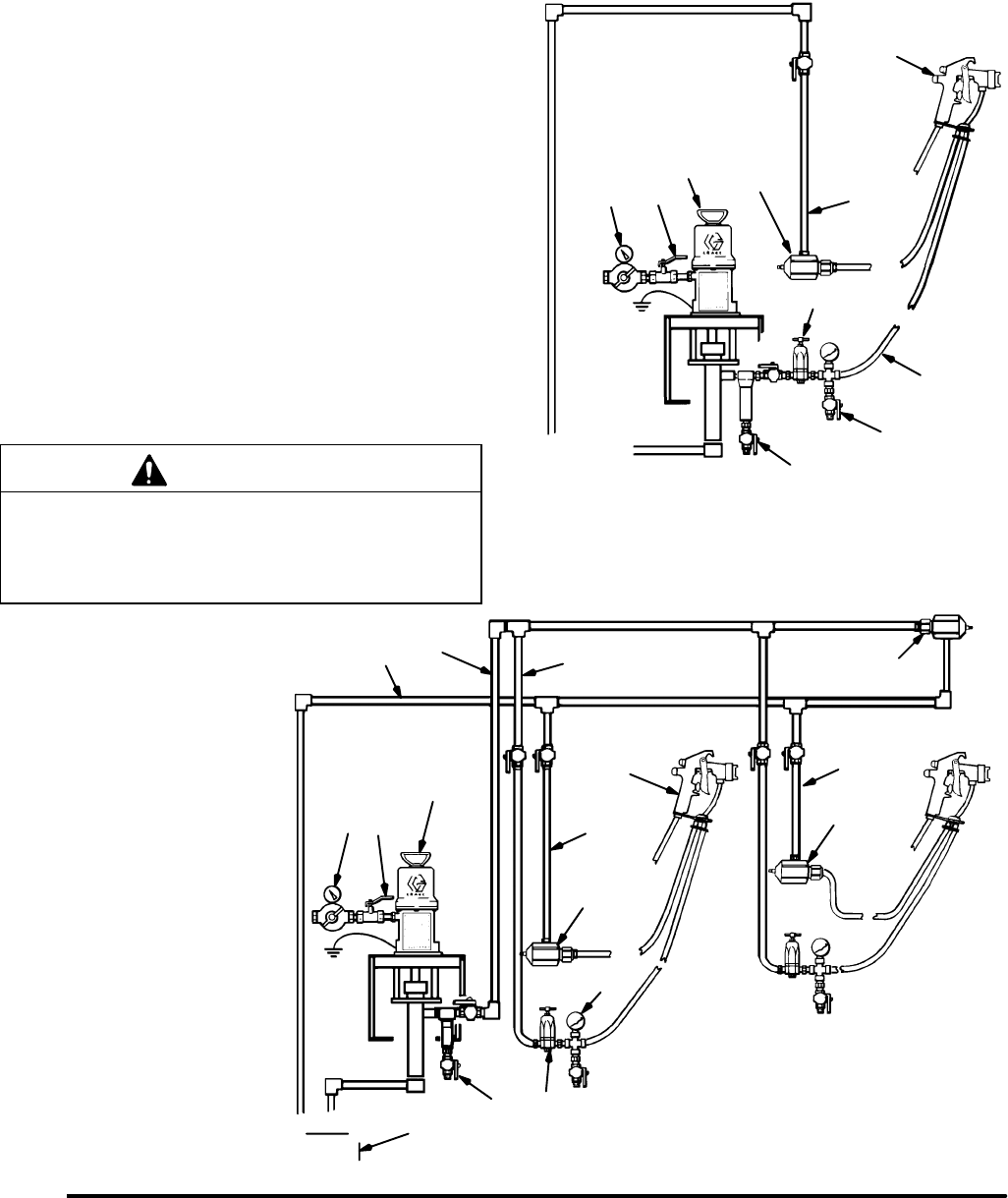

Fig. 1

KEY

A Air Regulator

B Bleed-Type Master Air Valve

C Pump

D Fluid Filter & Drain Valve

E Main Fluid Supply Line

F Gun Fluid Supply Line

G Fluid Regulator

H Fluid Pressure Gauge

& Drain Valve

J Air-Assisted Airless Spray Gun

K Back Pressure Valve

L Fluid Return Line

M Main Circulating Line

N Fluid Supply Container

AB

C

D

E

F

J

K

M

H

K

L

C

J

Single Circulating Spray Station

Multiple Circulating Spray Station

G

N

F

K

L

A

B

D

G

H

K

L

3307892

Installation

NOTE: The Typical Installations shown in Fig. 1 are

only guides for selecting and installing a circulating

system. Contact your Graco representative or Graco

Technical Assistance (see back page) for assistance in

designing a system to meet your particular needs.

Install the back pressure valve (K) in the spray gun

return line (L) as shown in the Typical Installation

drawing below or at right. Using pipe sealant on pipe

threads, connect the lines to the 3/8 npt(f) inlet and

outlet. Be sure the flow direction agrees with the

markings on the valve housing.

If more than one spray station is used, install a back

pressure valve (K) in the circulating line (M), after the

last spray station to maintain proper system pressures.

NOTE: The two 1/4–20 tapped mounting holes on the

side of the valve housing are for mounting the valve

when flexible fluid lines are used.

The back pressure valve was tested in lightweight oil.

Flush the entire system with a solvent compatible with

the fluid being sprayed or dispensed, then test the

system.

CAUTION

The new system must be cleaned and tested thor-

oughly before admitting fluid to the back pressure

valve, to avoid contaminants clogging or damaging

the valve.