Pressure Relief Procedure

4 312145G

Pressure Relief Procedure

Follow this Pressure Relief Procedure

whenever you are instructed to relieve

pressure, stop spraying, check or service

equipment, or install or clean spray tip.

1. Engage trigger lock.

2. Shut off pump.

3. Disengage trigger lock.

4. Hold a metal part of the gun firmly to a

grounded metal pail. Trigger the gun to

relieve pressure.

5. Engage trigger lock.

6. Open fluid drain valve (see System

Requirements). Leave drain valve open.

If pressure is not fully relieved:

• Spray tip is clogged. For RAC tip, see

Cleaning Tips/Clearing Clogs, page 6.

For flat tip, slowly loosen tip guard retaining

nut to relieve pressure. Remove and clear

tip.

• Hose is clogged. Slowly loosen hose end

coupling to relieve pressure. Clean hose

obstruction.

System Requirements

• Install a bleed-type master air valve on a

pneumatic pump air supply line to relieve

air trapped between this valve and pump

after air regulator is shut off. Trapped air

can cause the pump to cycle unexpectedly.

• Install a fluid drain valve between the pump

and gun to relieve pressure in displace-

ment pump, hose, and gun. Triggering to

relieve pressure may not be sufficient. See

Pressure Relief Procedure.

Grounding

Check your local electrical code and

pump/sprayer manual for detailed grounding

instructions.

• Spray gun: ground through connection to a

grounded fluid hose and pump/sprayer.

• Fluid hose: use only grounded hoses.

• Fluid supply container: follow local code.

• Object being sprayed: follow local code.

• Solvent flushing pails: follow local code.

Use only conductive metal pails placed on

a grounded surface. Do not place pail on a

nonconductive surface, such as paper or

cardboard, which interrupts grounding

continuity.

• To maintain grounding continuity when

flushing or relieving pressure: hold metal

part of gun firmly to side of a grounded

metal pail, then trigger gun.

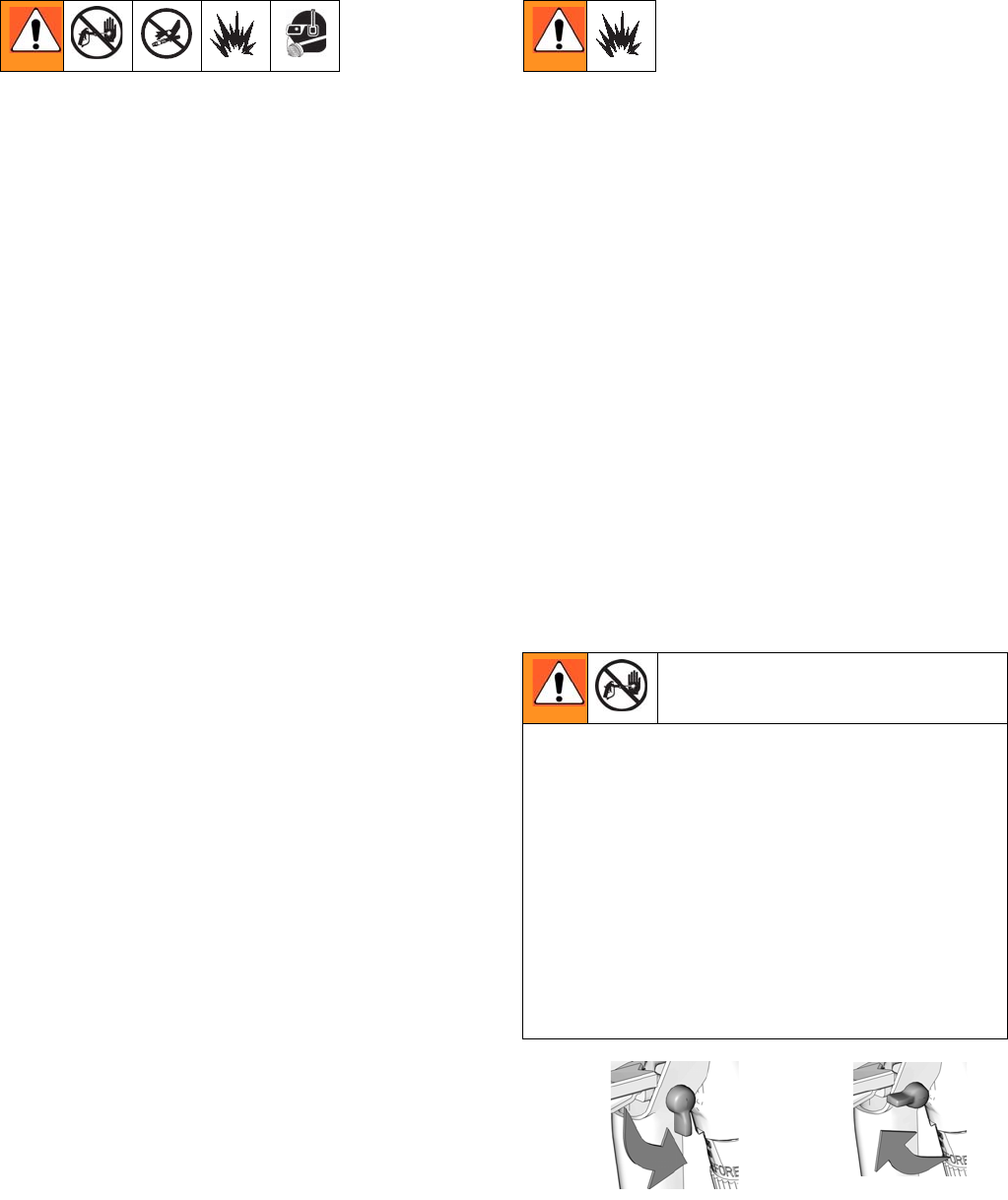

Gun Trigger Lock

To prevent injury when the gun is not in use,

always engage the gun’s trigger lock if unit is

being shut down or left unattended. A

wallet-sized warning card with important

injection treatment information is included

with the gun. Additional cards are available at

no charge. Provide a card to all operators.

The trigger lock must move freely, and easily

snap into a locked position. If the trigger lock

is damaged or movement is restricted,

replace with new trigger kit (16) immediately.

Trigger

Trigger

Locked

(no spray)

Unlocked

(spray)

ti5048b

ti5049b