6 308666

Installation

Mounting the Elevator Base to the Floor

You must mount th e elevator base to the floor

before you operate this equipment.

WARNING

1. Positi on the elevator where there is at least 9 feet

(2.75 meters) of overhead clearance.

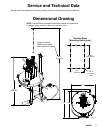

2. Mark and drill holes in the floor for 0 .5-in. (13 mm)

mounting bolts. See the mounting layout in the

Dimensional Drawing on page 7.

3. Level the elevato r base, using shim s if necessary,

and bolt the base firmly to the fl oor.

Grounding

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, th e mounting

cover and all electrically conductive objects or devices

in th e dispensing a rea must be properly grounded.

Check your local electrica l code fo r detailed grounding

instru ctions for your area and type of equipment.

To ground the dispenser, connect the end of th e

ground wire to a true earth ground.

Operation

WARNING

MOVING PARTS HAZARD

To reduce the risk of serious injury,

including cuts, amputation of fingers by

the agitator blades, and splashing in

the eyes or on the skin, always shut off the

agitato r (disconnec t the air line from the agitator)

before you raise, check, or repair the agitator .

Never operate the agitator when the elevator is

raised. See Moving Parts Hazard on page 3.

Startup

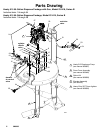

See the Parts Drawing on page 4.

1. Flush the dispenser before first use.

NOTE: The pump was tested in water. To elimi-

nate possible contamination of the fluid you are

pumping, before you use the dispenser, flush the

pump thoroughly with a solvent compatible to th e

solvent you are dispensing.

2. Ensure that the needle valve on the agitator is

closed and that the dispenser ball valve (19) is

closed.

3. Connect the air supply line to the male air line

fitting (22).

4. Using the needle valve on the agitator to adjust the

agitato r speed, gradually increase the speed until

you can see (through the inspection port in the

drum cover) movement in the surface of th e liquid,

but do not increase the agitator speed enough to

create a vorte x in the surfac e of the liquid. If the

surface begins to vortex, decrease the agita tor

speed to prevent air entrainment.

NOTE: Always maintain moderate agitator speed,

which is approximately 50 rpm of the agitator

blades. Ex cessive agitator speed may cause

vibration, foaming of fluid, and incr eased wear on

parts . Always agitate fluid thor oughly before

supplying it to the dispens ing equipment, and

continue agitating fluid while the dispens ing equip-

ment is being supplied.

5. Use the regulator (10) and ball valve (19) to control

the pressure and operation of the pump (1) .

6. Raise or lower the elevator by pulling out or push-

ing in the air control valve (a push-pull handle) on

the rim of the drum cover. Normal operation

requires only a few seconds for air press ure to

build up and raise the elevator or to exhaust and

lower the elevator.

NOTE: To increase the operating speed of the

elevator, loosen the hex nut on the res tricto r valve,

and tu rn the valve needle out. To decrease the

operating speed, tu rn the valve needle in. The

restrictor valve is on the top of the elevator, as

shown i n the Parts Drawing.