23

307-712

SERVICE

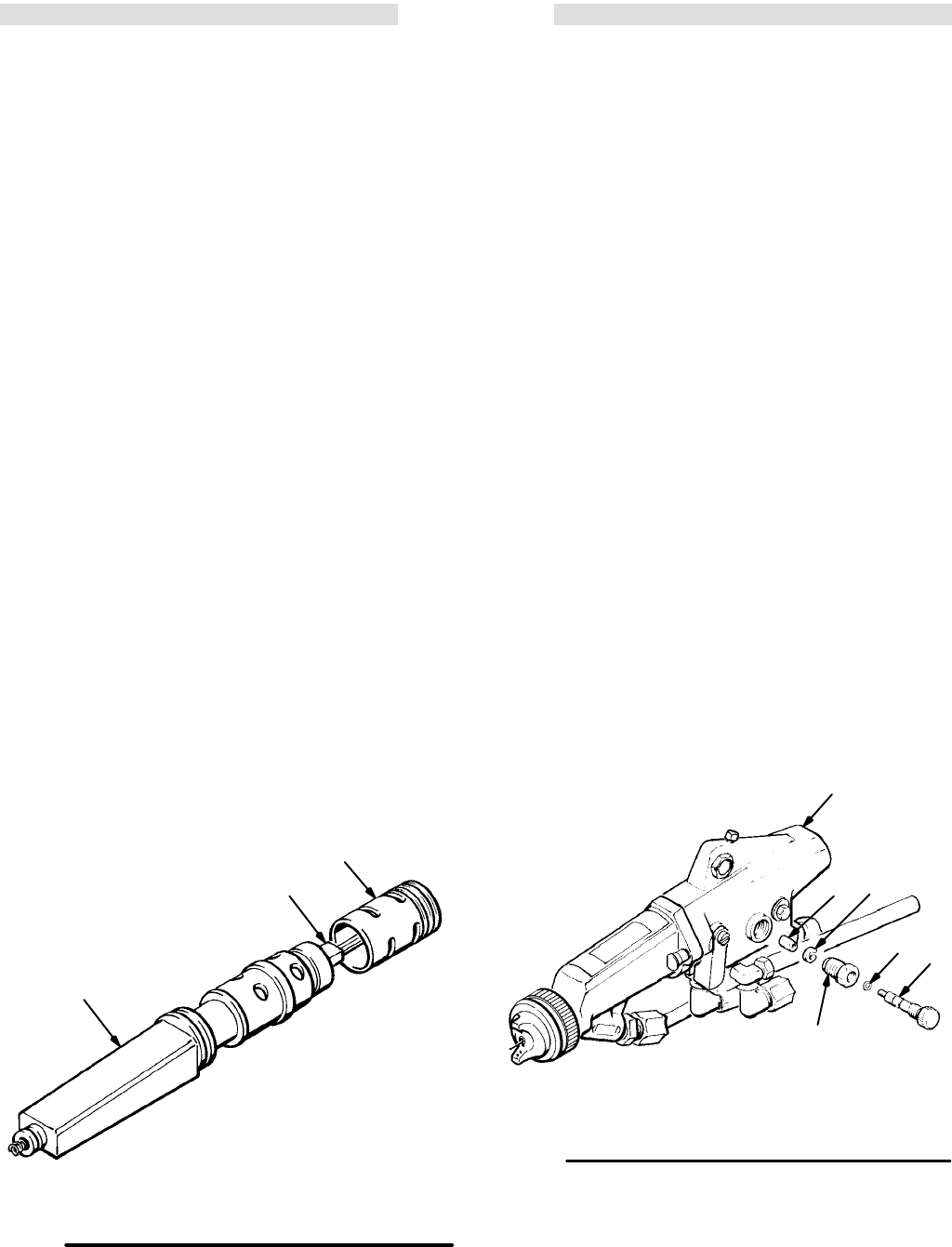

Turbine Alternator Removal

1. Remove power cartridge from the gun body as

described under Power Cartridge Replacement.

2. Carefully twist the turbine alternator (2a) counterĆ

clockwise and pull it off the power supply (5) until

just disengaged from the coupling. Then continue

to slowly pull the turbine alternator away from the

power supply, disconnecting the 3Ćwire connector

(HH). See Fig 19.

3. Using an ohmmeter, test the coil in the turbine alterĆ

nator (2a). Measure the resistance between the two

outer terminals of the 3Ćwire connector (HH). The

resistance should be 3 to 5 ohms. If the reading varĆ

ies from this value, replace the alternator.

4. Measure the resistance between each outer termiĆ

nal of the 3Ćwire connector (HH) and the turbine alĆ

ternator housing. The resistance should be infinite.

If the resistance is not infinite, replace the alternator.

5. Partially connect the 3Ćwire connector (HH) onto the

prongs inside the power supply (5). See Fig 19. UsĆ

ing a small screwdriver, push the connector onto the

prongs until seated.

6. Slide the turbine alternator (2a) onto the power supĆ

ply, being sure to align the coupling between the

power supply and the turbine alternator housing.

Then twist the turbine alternator clockwise to lock

the coupling.

7. Install the power cartridge in the gun body as

described under Power Cartridge Replacement.

Fig 19

KEY

HH 3-wire Connector

2a Alternator

5 Power Supply

5

HH

2a

Fan Air Valve Replacement

1. Place a wrench on the flats of the valve housing (55)

and remove it from the gun body (1). See Fig 20.

2. Remove the retaining ring (46).

3. Rotate the air adjusting screw (56) counterclockĆ

wise until it is disengaged from the valve housing

threads. Pull the adjusting screw out of the valve

housing (55).

4. Clean all the parts and inspect them for wear or

damage. If replacing the seal (47), unscrew it clockĆ

wise and remove it from the adjusting screw.

5. Apply medium grade thread sealant to the small

threads on the end of the adjusting screw (56) and

install a new seal (left hand thread).

6. When reassembling the fan air valve, lubricate the

o-ring (54) and the adjusting screw threads with

petroleum jelly.

7. After the retaining ring (46) is installed on the adjustĆ

ing screw (56), back the adjusting screw out of the

valve housing (55) until it bottoms out against the reĆ

taining ring.

8. Apply Teflonr paste to the threads of the valve housĆ

ing (55) and install it in the gun body (1). Torque the

housing to 1.1-1.4 NSm (10-12 in-lb).

Fig 20

KEY

1 Gun Body

46 Retaining Ring

47 Valve Seal

54 OĆRing

55 Valve Housing

56 Adjusting Screw

47 46

56

55

1

54

Apply Teflon paste.

Torque to

1.1-1.4 NSm

(10-12 in-lb)