Troubleshooting

311365G 11

Troubleshooting

Mechanical/Fluid Flow

Relieve pressure; page 9.

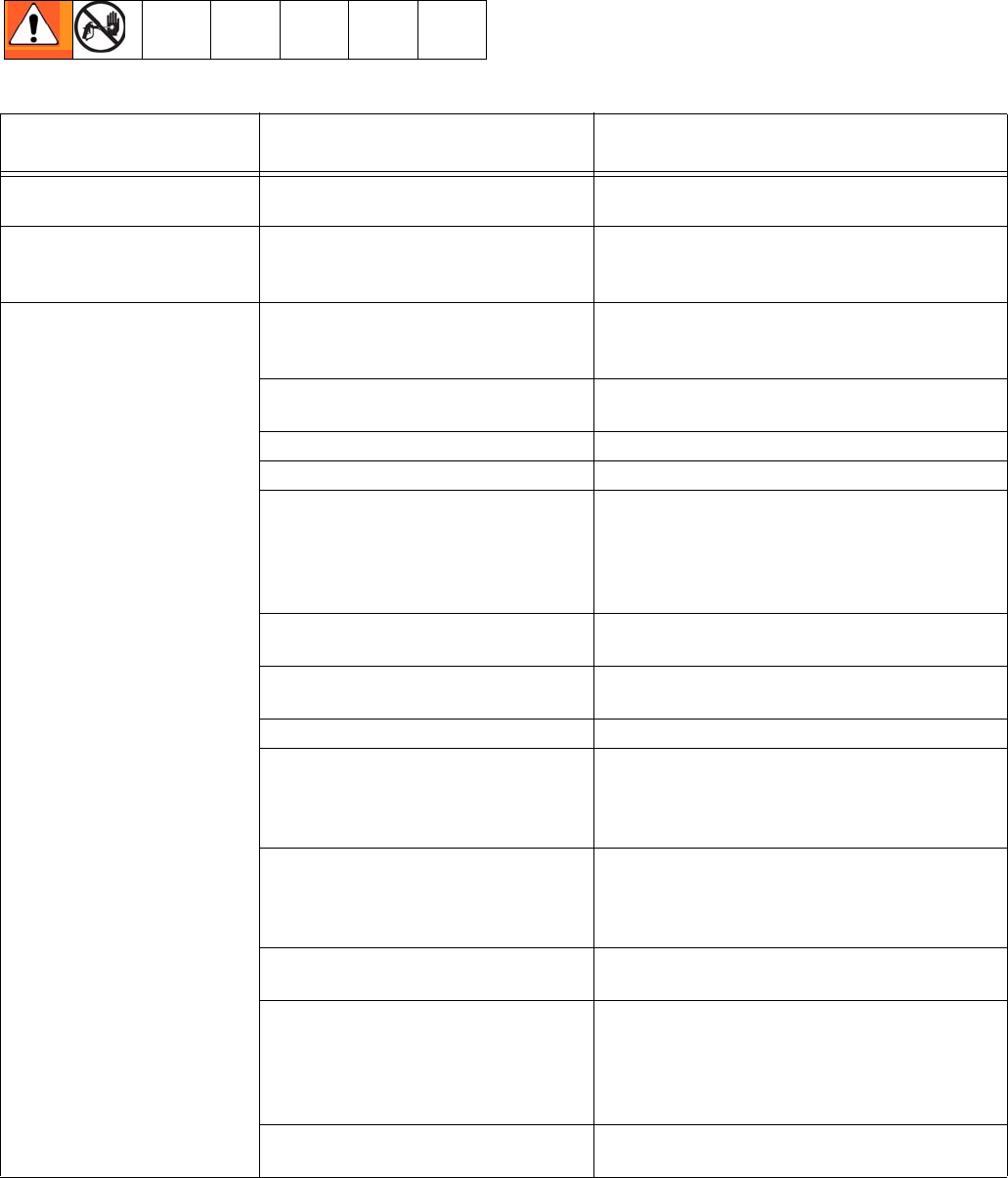

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK, refer to this column

E=XX is displayed 1. Fault condition exists 1. Determine fault correction from table,

page 13.

False tripping of WatchDog

system. EMPTY is dis-

played. Pump does not run.

1. Operating conditions out of

WatchDog parameters. Pump

output is low, see below.

1. Turn pressure down. Refer to operation

manual for adjusting. Operate without

WatchDog active; see operation manual.

Pump output is low 1. Spray tip worn 1. Follow Pressure Relief procedure Warn-

ing, then replace tip. See your separate

gun or tip manual.

2. Spray tip clogged 2. Relieve pressure. Check and clean spray

tip.

3. Paint supply 3. Refill and reprime pump.

4. Intake strainer clogged 4. Remove and clean, then reinstall

5. Intake valve ball and piston ball

are not seating properly

5. Remove intake valve and clean. Check

balls and seats for nicks; replace if neces-

sary; see pump manual 310643 or

310894. Strain paint before using to

remove particles that could clog pump.

6. Suction hose connections 6. Tighten any loose connections. Check for

missing or damaged seals.

7. Fluid filter, tip filter, or tip is

clogged or dirty.

7. Clean filter; see operation manual.

8. Prime valve leaking 8. Relieve pressure. Repair prime valve.

9. Verify pump does not continue to

stroke when gun trigger is

released. (Prime valve not leak-

ing.)

9. Service pump; see pump manual 310643

or 310894.

10. Leaking around throat packing

nut which may indicate worn or

damaged packings.

10. Replace packings; see pump manual. Also

check piston valve seat for hardened paint

or nicks and replace if necessary. Tighten

packing nut/wet-cup.

11. Pump rod damage 11. Repair pump. See pump manual 310643

or 310894.

12. Low stall pressure 12. Turn pressure knob fully clockwise. Make

sure pressure control knob is properly

installed to allow full clockwise position. If

problem persists, replace pressure trans-

ducer.

13. Piston packings are worn or

damaged

13. Replace packings; see pump manual

310643 or 310894.