-24- G0445/G0582/G9962Z/9962ZX Wide Belt Sander

Sanding Workpiece

Typically, no more than 0.5mm (approx.

1

⁄64") of

material is removed during each pass. Attempts

to remove too much material can cause jamming,

wood burning, rapid paper wear or tearing, poor

finish, short motor life. Make sure that you mea

-

sure the workpiece thickness before and after

every pass.

The following is the correct sanding operating

procedure:

1. Put on safety glasses, a dust mask, and

hearing protection!

2. Turn ON the dust collector.

3. On the initial pass, set the table so the sand-

paper is 0.25" above the workpiece.

Note: This initial pass setting eliminates the

chance of overloading the sander on

unde-

tected high points on the workpiece.

4. Continue to raise the table 0.0625" between

each successive pass until the sander begins

to sand the workpiece.

NOTICE

It may be necessary to send wide stock

through the sander two or three times

between table height adjustments. This

reduces the likelihood of burning the wood

if there is a high spot.

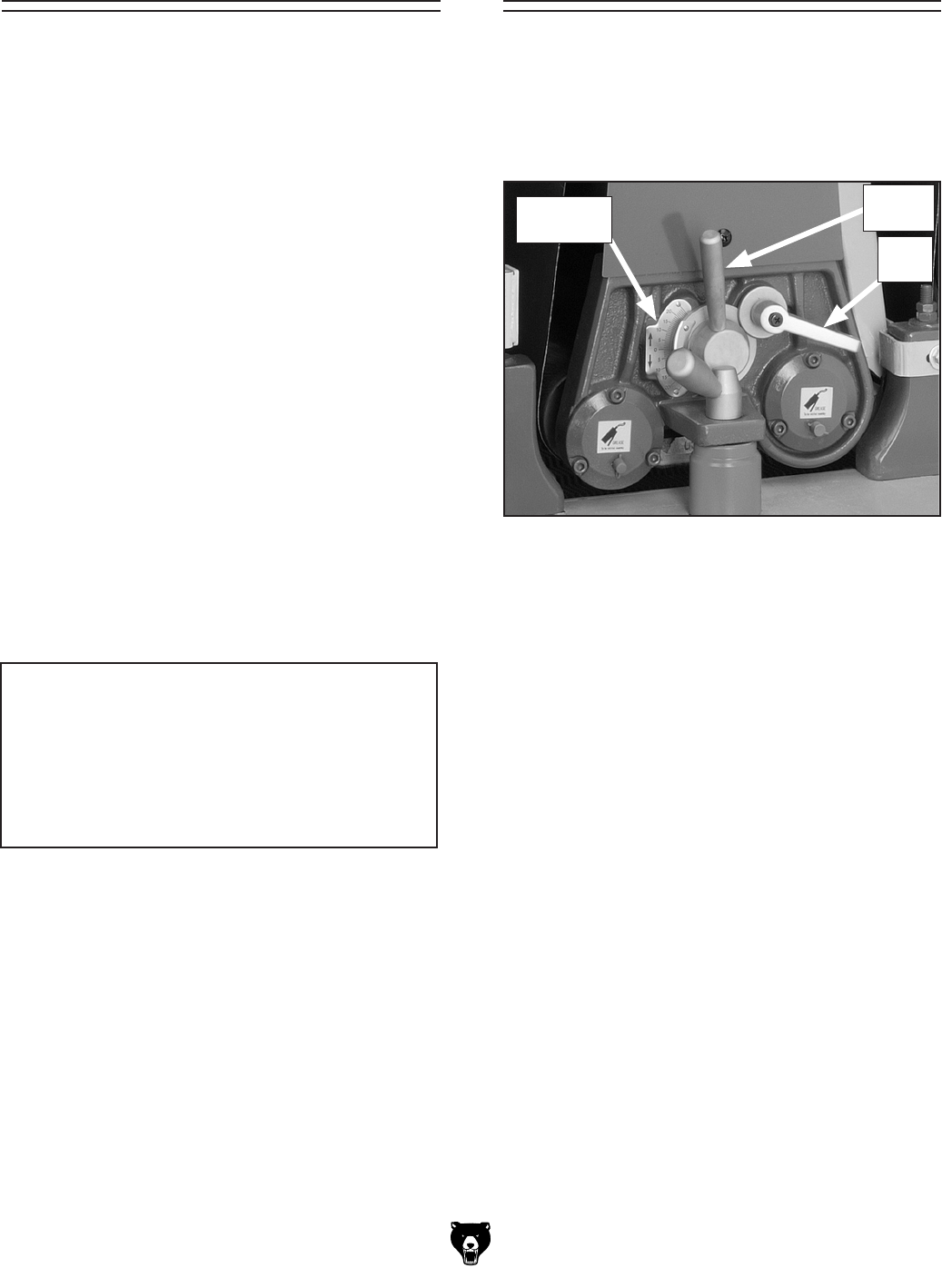

Platen Adjustment

Your sander is equipped with an adjustable felt

platen and graphite pad for those extra sensitive

sanding operations.

The platen position allows

for 3 basic types of sanding. These different posi

-

tions can be adjusted by rotating the height lever

shown in

Figure 18.

Figure 18. Platen height controls.

Lock

Lever

Height

Lever

Scale and

Pointer

Using the platen:

For an initial heavy-sanding pass, the platen is

raised above the level of the drums, and the table

is adjusted to set sanding depth. The drums do all

the work using #100 grit or coarser sandpaper

,

but you will have a rough finish.

For an intermediate-finishing pass, the platen is

lowered so it is level with the drums

, and the table

is adjusted to set sanding depth. The best belt grit

for this position is #100-#180.

For a final-sanding pass, do not adjust the table

to adjust the sanding depth. The drums must

touch the workpiece without doing any sanding.

The platen should be lowered to 0.2 to 0.5 mm

below the sanding drums. You can lower the

platen up to 2 mm below the drums for short

intervals, but streaking, burn marks, and prema

-

ture graphite/platen wear can occur if this setting

is abused. The best belt grit for the

final-sanding

pass is #180 or finer.

Note: The platen scale is broken down in arbi-

trary increments.