Model G0464/G0465/G0467/G0468/G0470 Air Compressors

-15-

SECTION 5: MAINTENANCE

Schedule

For optimum performance from your

machine, follow this maintenance sched-

ule and refer to any specific instructions

given in this section.

Daily

1. Check the oil level! Use the sight glass

on the crankcase to make sure the oil

reservoir is at the correct level.

2. Check for worn or damaged cords and

plugs.

3. Check for any other condition that

could hamper the safe operation of this

machine.

4. When finished using the air compres-

sor, drain the condensation from the

tank as instructed in Draining Tank

on Page 16, and leave the drain valve

open until the next use.

The air compressor will turn ON

automatically when it is set on AUTO.

When performing maintenance make

sure the AUTO/OFF lever is in the

OFF position, the compressor is

unplugged, and the air pressure has

been bled out of the tank.

Operating this equipment has the

potential to cause eye injury and

hearing loss. Always wear eye and

ear protection when operating an air

compressor. Be certain the safety

protection you wear meet the appro-

priate standards of the American

National Standards Institute (ANSI).

If the compressor is used on a daily basis,

perform the following checks each week.

Weekly

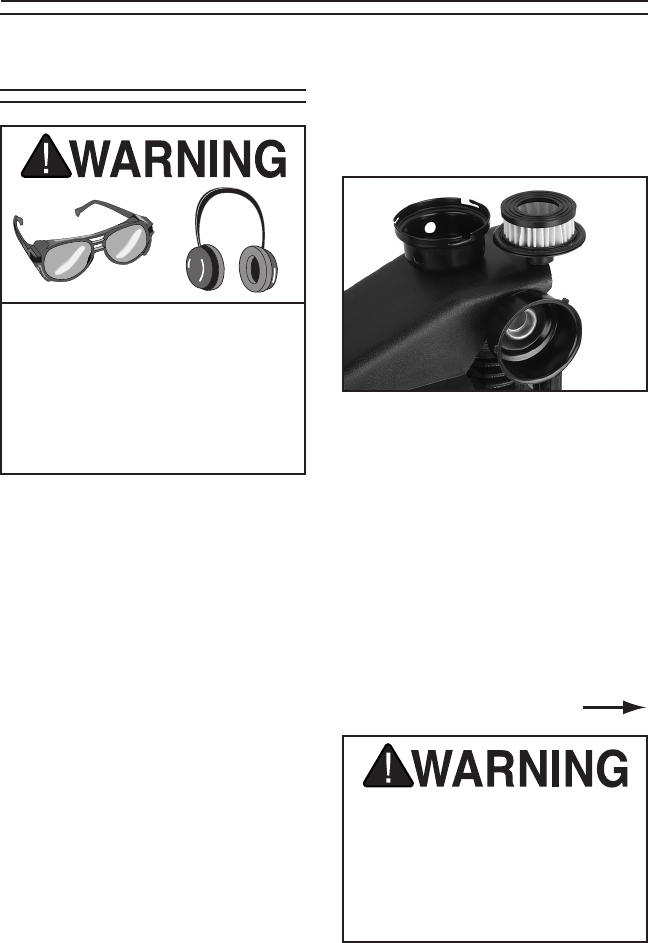

1. Blow dirt and dust off of the air filter

(Figure 9), then re-install.

2. Check for loose bolts or fittings.

3. Clean off all dirt and dust from the cylin-

der head, motor, fan, air lines, exhaust

pipe, couplers and frame. Dirt can lead

to overheating.

4. Check air lines and connectors to make

sure they are in good condition.

5. Pull the safety drain valve to make sure

it is working properly (see Draining

Tank on Page 16).

Figure 9. Air filter foam element.

Continued on next page