G0463 Small Mill/Drill

-15-

Test Run and

Spindle Break-in

The Model G0463 has two speed ranges: Low

range is 0–1000; high range is 0–2000 RPM.

It is essential to closely follow the proper break-in

procedures to ensure trouble free performance.

Complete this process once you have familiarized

yourself with all instructions in this manual.

To begin the start up and break-in procedure:

1. Follow all lubrication procedures highlighted

in Lubrication in Section 6: MAINTENANCE

on Page 24.

2. Make sure there are no obstructions around or

underneath the spindle. Remove the drawbar

if there is no arbor or collet in the spindle.

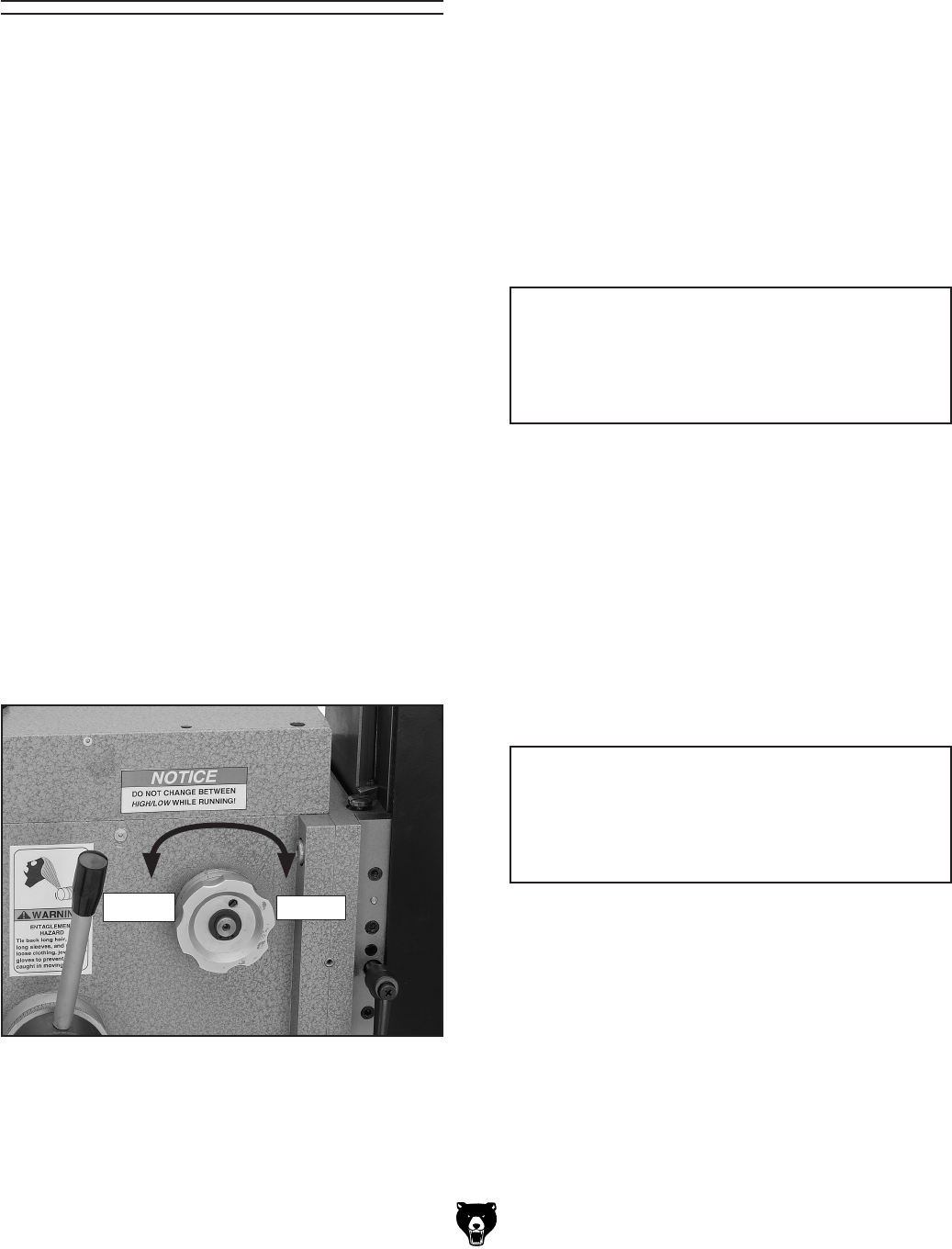

3. With the spindle at a complete stop, shift

the HIGH/LOW gear change knob into the

low range (see

Figure 7). Set the forward/

reverse switch to FWD.

Note: If the knob will not rotate into gear at

first, rotate the spindle by hand while holding

light pressure on the knob. When the gears

engage, the knob will rotate into place.

Failure to follow start up and spindle break-

in procedures will likely cause rapid deteri

-

oration of spindle and other related parts.

NOTICE

4. Make sure all switches are OFF and connect

the mill/drill to the power source

.

5. Turn the main power switch ON & Spindle

RPM control

ON and let the mill run for a

minimum of 10 minutes on a low speed. Th

e

mill/drill should run smoothly with minimal

noise and vibration.

—If you suspect the mill/drill is not working

correctly, shut the mill/drill

OFF and correct

the problem before proceeding further.

—If the mill/drill is running smoothly, pro

-

ceed.

Figure 7. HIGH/LOW gear change knob.

6. Slowly increase the RPM and allow it to run

at a medium RPM for another ten minu

tes.

7. Slowly increase the RPM and allow it to run

at a high RPM for another ten minu

tes.

8. Turn the mill/drill OFF. Switch to the high

range and rep

eat Steps 4–6.

9. Set the forward/reverse switch to REV and

repeat the previous process.

DO NOT attempt to change between high

and low speed ranges with the spindle

ON.

Damage to the spindle gearing will occur.

NOTICE

High

Low