Model G0466/G0469 Air Compressors

-18-

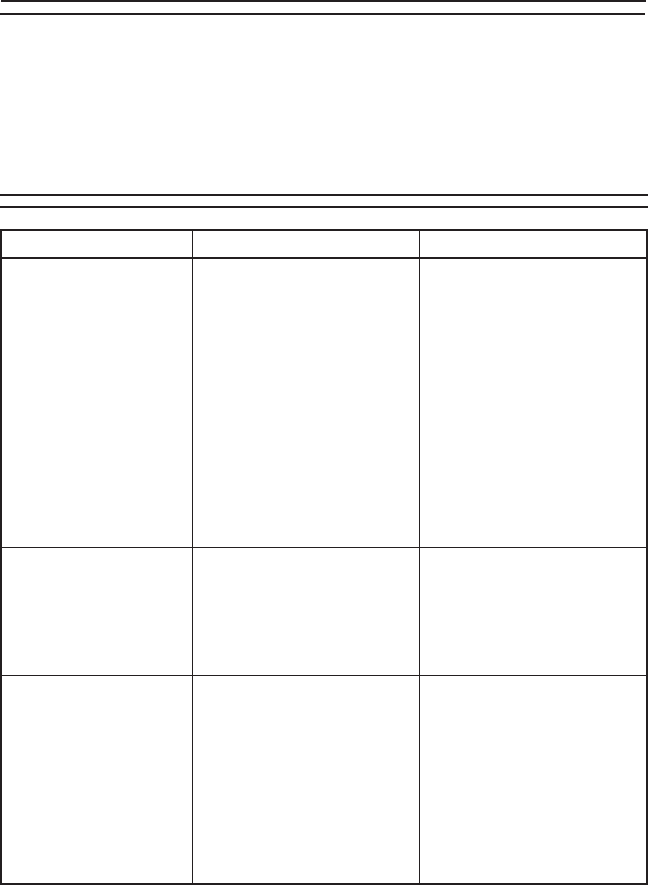

SECTION 6: SERVICE

This section is provided for your convenience—it is not a substitute for the Grizzly Service

Department. If you need help troubleshooting, replacing parts, or you are unsure of how

to perform the procedures in this section, then feel free to call our Technical Support at

(570) 546-9663.

Symptom Possible Cause Possible Solution

Motor will not start.

1. Tank already pressurized.

2. Thermal overload switch

has tripped.

3. Low voltage.

4. Short circuit in motor or

cord, or loose connec-

tions.

5. Incorrect fuses or circuit

breakers in power line.

6. Pressure switch is bad.

1. Motor will not start if tank

is fully pressurized.

2. Wait for motor to cool.

3. Check power line for

proper voltage.

4. Inspect all connections on

motor for loose or shorted

terminals or worn insula-

tion.

5. Install correct fuses or cir-

cuit breakers.

6. Replace the pressure

switch.

Motor fails to develop

full power (output of

motor decreases rapidly

with decrease in volt

-

age at motor terminals).

1. Power line overloaded

with lights, appliances,

and other motors.

2. Undersized wires or cir-

cuits too long.

1. Reduce load on power

line.

2. Increase wire sizes or

reduce length of the cir-

cuit.

Motor overheats and

thermal overload turns

motor OFF

.

1. Cooling fins dirty.

2. Air filter clogged.

3. Compressor is running

too long without a break.

4. Air circulation through the

motor restricted.

1. Clean cylinder fins and

motor area.

2. Inspect and clean air filter.

3. Do not use air tools with

CFM needs that exceed

the compressor CFM rat-

ing.

4. Clean out motor to pro-

vide normal air circula-

tion.

Troubleshooting