-34-

G0633/G0634 Jointer/Planer Combo Machine

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person

-

al injury.

SECTION 6: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

:

• Clean unpainted cast iron parts of jointer and

planer tables

• Lubricate feed rollers

Weekly Check:

• Clean cutterhead

Monthly Check:

• Inspect V-belt tension, damage, or wear

• Clean/vacuum dust buildup from inside cabi

-

net and off motor

• Lubricate worm gear

• Lubricate roller chains

• Lubricate elevation lead screw

• Lubricate worm shaft

Schedule

Vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth—this

ensures moisture from wood dust does not remain

on bare metal surfaces. Treat all unpainted cast

iron and steel with a non-staining lubricant after

cleaning. We recommend products like SLIPIT

®

,

G96

®

Gun Treatment, or Boeshield

®

T-9 (see

Page 32 for more details).

Cleaning

V-Belts

V-belt removal and replacement involves remov-

ing the V-belts, rolling them off of the pulleys,

replacing them with new belts, then retensioning

them.

Always replace V-belts as a set, or belt tension

may not be even among the belts and may cause

premature belt failure.

Consider replacing stock belts with Power Twist

V-belts (see

Page 32) to reduce vibration and

noise, and increase belt lifespan.

To adjust/replace belts the V-belts:

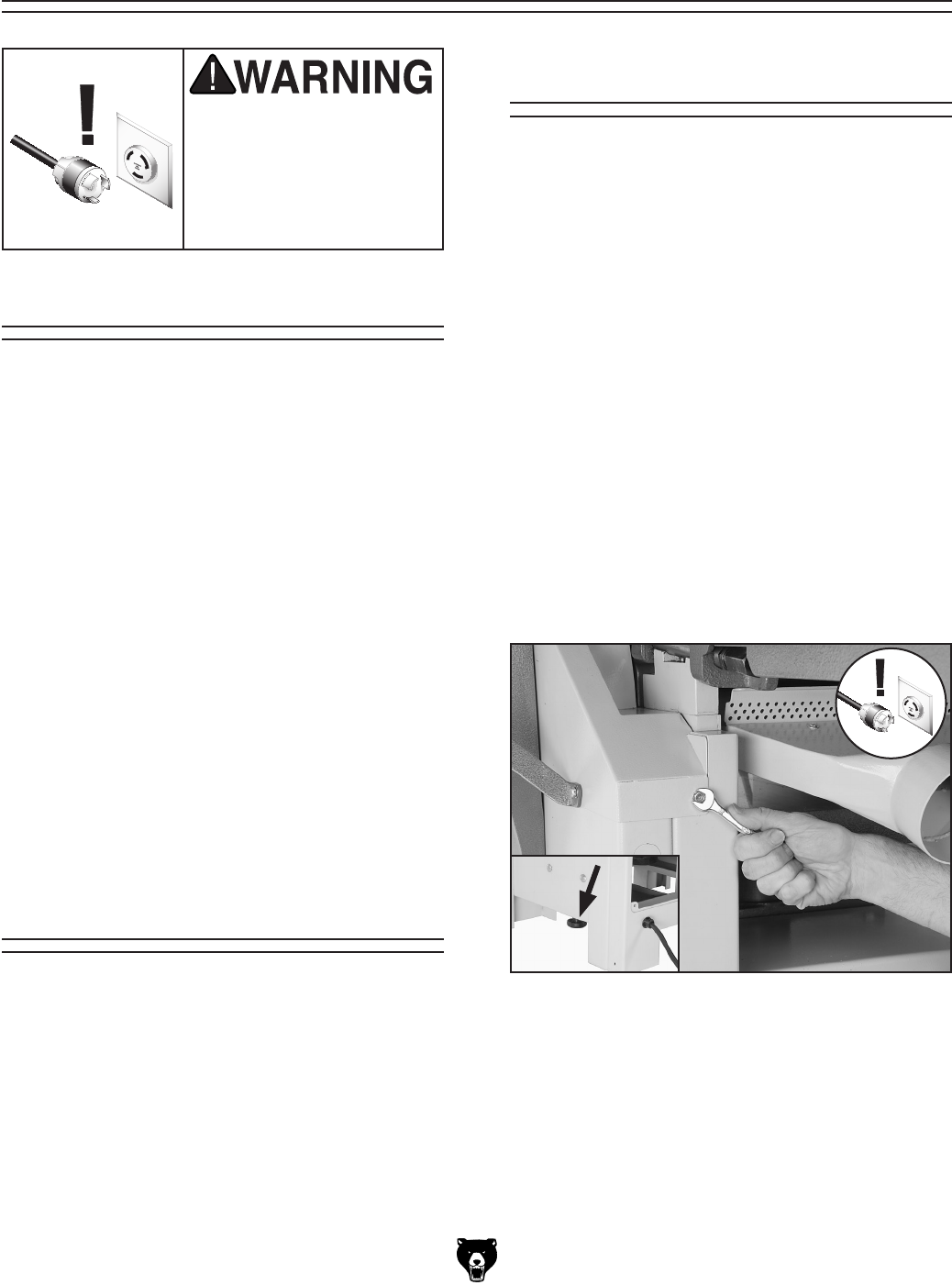

1. DISCONNECT THE JOINTER/PLANER

FROM THE POWER SOURCE!

2. Remove the four hex bolts securing the V-

belt cover (see

Figure 46).

3. Remove the fence and fence bracket, then

remove the motor access cover and belt ten

-

sion knob (

Figure 46).

Figure 46. Removing bolts on V-belt cover and

belt tension knob (inset).