ON/OFF SWITCH

The Model G1131 Radial Drill Press is

equipped with a key-activated ON/OFF

switch for added safety. To switch on the

drill press:

1. Insert the safety key into the switch

mechanism located at the front of the

spindle assembly.

2. Flip the key to the ON position.

3. When drilling is complete, switch the

key to the OFF position. When the drill

press is not in use, remove the key from

the switch and store it in a safe place.

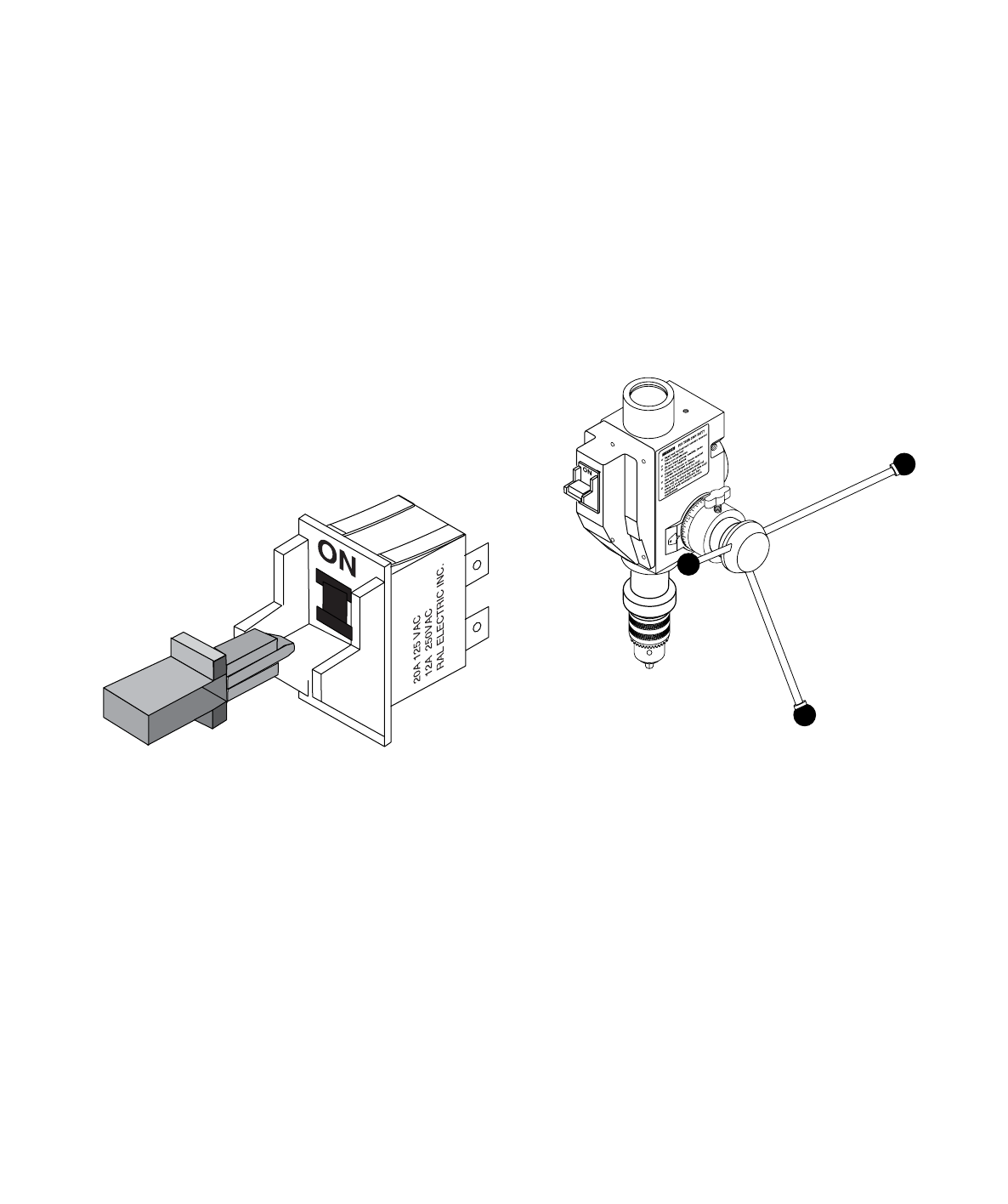

DEPTH STOP ADJUSTMENT

The Model G1131 Radial Drill Press offers

an adjustable depth stop for precision con-

trol when making repetitive cuts to an exact

depth. To set the depth stop:

1. Adjust your table so your workpiece is

close enough to your drill bit to allow

travel to the full depth of cut you desire.

2. Drill your first hole to the depth you

seek.

3. Turn off the drill press and lower the

spindle until the bit reaches the base of

your cut. With one hand, maintain that

depth.

4. Loosen the depth stop knob located at

the hub of the spindle height wheel and

rotate the depth scale counterclockwise

until the pointer reaches zero.

5. Tighten the depth stop knob and

release the height wheel.

Once the procedure is complete, your drill

press will deliver uniformly deep holes until

you choose to change your settings.

SPINDLE RETURN SPRING

Although the spring-operated spindle return

is set at the factory, there may come a time

when it’s necessary to adjust its level of

tightness.

Should adjustment be required, carefully

loosen the two locknuts on the outside of the

spring assembly (located on the spindle

housing)

Firmly grasp the spring housing as you

loosen the locknuts and gently pull the hous-

ing away from the spindle until the notches

clear the retainer tab. Turn the housing

clockwise – one notch at a time – until the

proper tension is attained. Tighten the lock-

nuts. Tighten the two nuts together using

two wrenches.