G7297 Disc Sander -15-

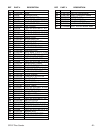

The most efficient way to get a perfect miter is to

cut the workpiece slightly long and sand it to the

desired dimension. Miter sanding can be done

easily with the miter gauge:

To perform miter sanding operations:

1. Loosen the knob on the miter gauge and

adjust the angle to the desired point. Tighten

the knob.

2. Slide the miter gauge into its slot and use it

to hold your workpiece in position. Note—

The miter gauge can be used in either direc-

tion in the slot to achieve the proper relation

of the workpiece to the disc.

3. With light, but firm pressure, push the work-

piece slowly into the downspin side of the

rotating disc (Figure 9).

Figure 9. Mitering with gauge angled.

Rotation

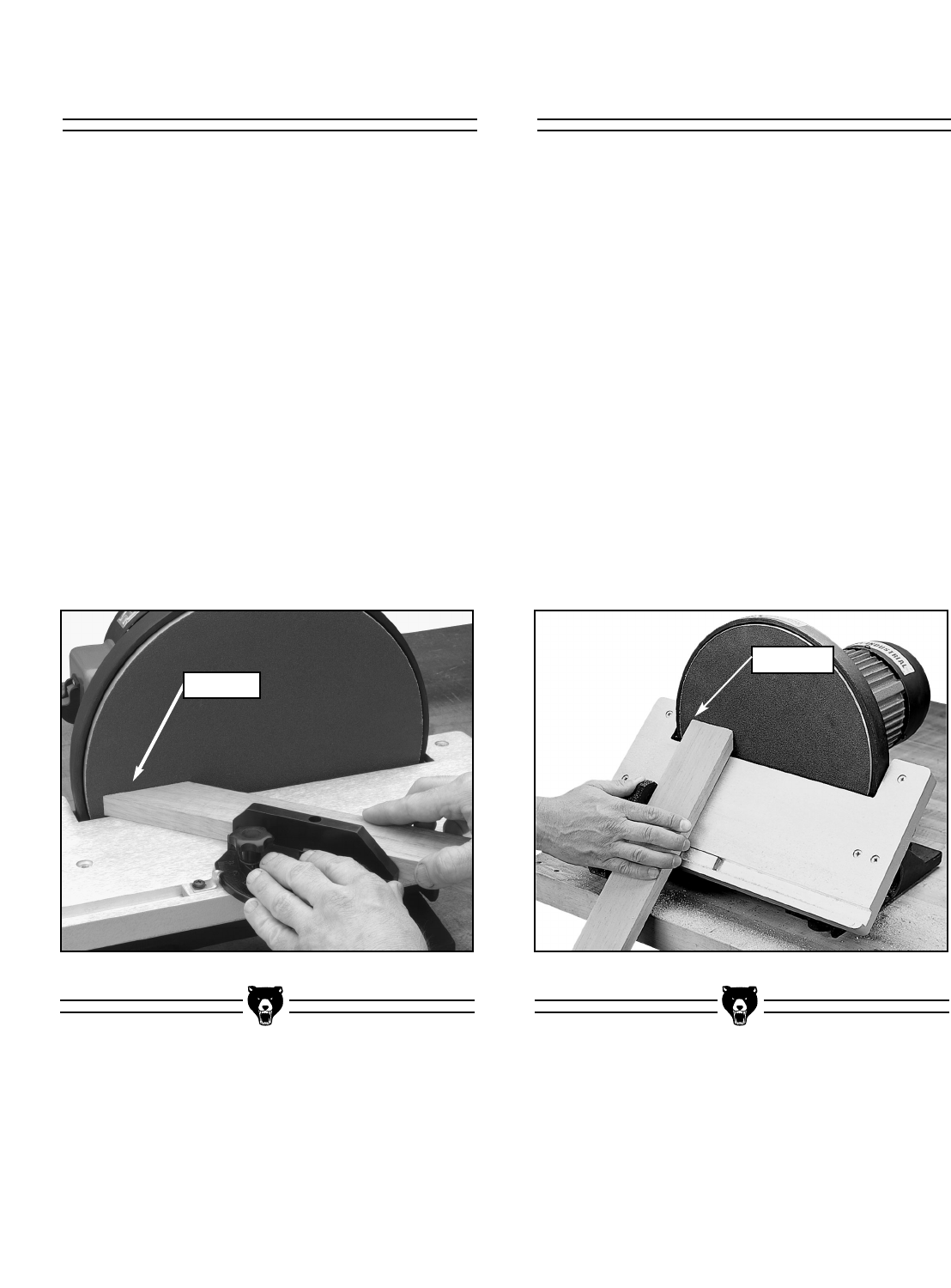

To perform angle sanding operations:

1. Loosen the handles securing the table.

2. Use the angle gauge to acheive the desired

table angle and tighten the handles. Note—

The disc table can be positioned from -15˚ to

35˚, relative to the plane of the sanding sur-

face. Whenever possible, sand with an open

angle where there is plenty of clearance

between the disc and the table. This will

avoid trapping the workpiece between the

sanding surface and the table.

3. Slide the miter gauge into its slot and use it

to hold your workpiece in position.

4. With light, but firm pressure, push the work-

piece slowly into the downspin side of the

rotating disc (Figure 10).

Figure 10. Mitering with table angled.

Rotation

Angle SandingMiter Sanding