-44-

G8144Z/G8145Z/G8146Z

Vertical Metal Cutting Bandsaw

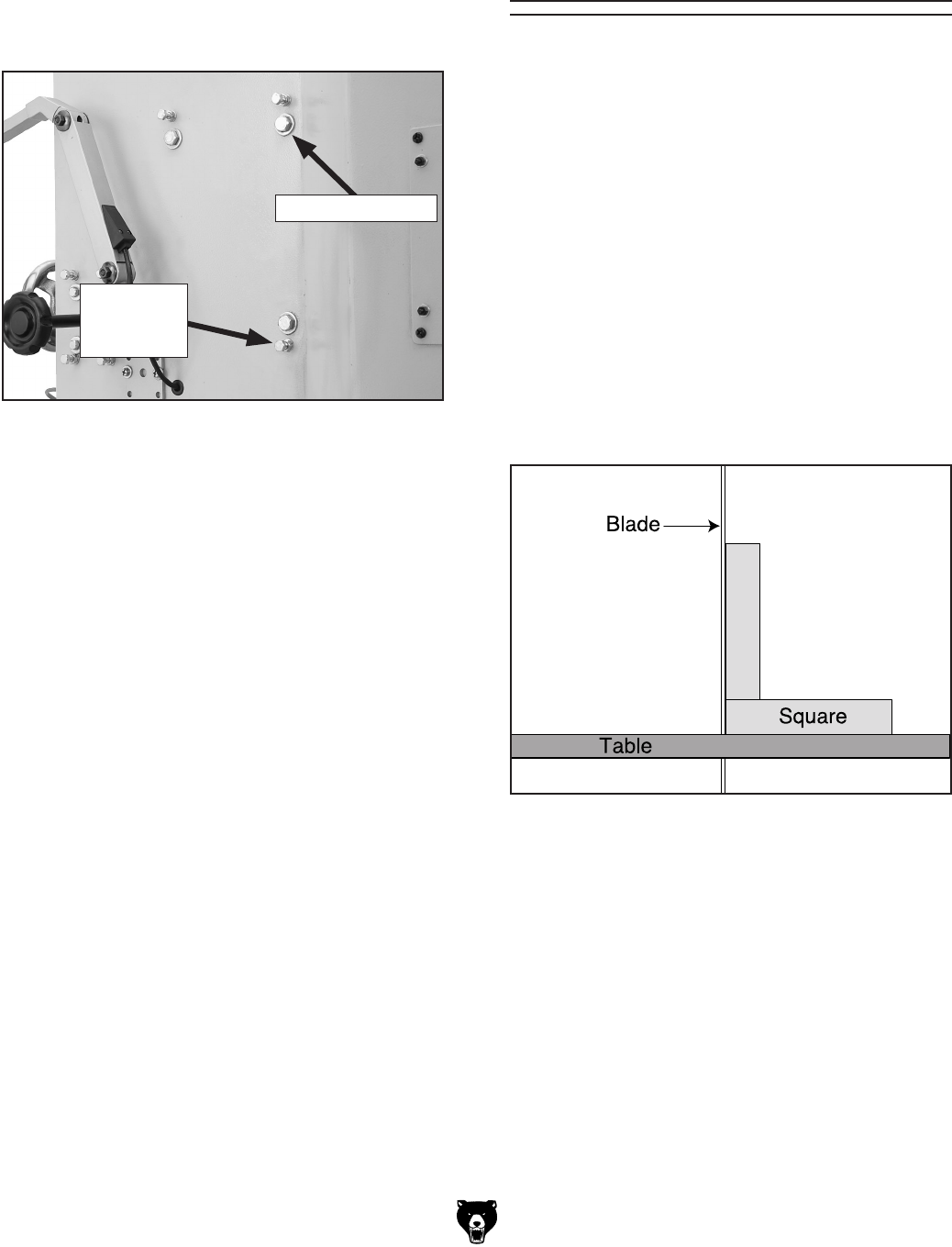

Aligning Table To

Blade

To ensure the angle accuracy of the cut, the table

must be 90° to the blade from front-to-back and

side-to-side. If the table is not square to the blade,

it needs to be adjusted.

To adjust the table square to the blade:

1. DISCONNECT BANDSAW FROM POWER!

2. Make sure the wheels are coplanar (Page

43) and the blade is properly tensioned

(Page 29).

3. Set the angle of the table to "0".

4. Use a square to check table alignment with

the blade, as shown in

Figure 53.

table alignment

Adjusting Upper Wheel

(Model G8146Z only)

The Model G8146Z upper wheel adjusting fasten-

ers consist of four locking hex bolts and four adjust

-

ing hex bolts with jam nuts (see Figure 52).

Figure 52. Model G8146Z upper wheel adjusting

fasteners.

Locking Hex Bolt

Adjusting

Hex Bolt

& Jam Nut

To adjust the Model G8146Z upper wheel:

1. Complete all steps in the Checking Wheel

Coplanarity subsection on Page 43.

2. Use a 17mm wrench to loosen the locking

hex bolts and a 12 mm wrench to loosen the

jam nuts on the upper wheel (see

Figure

52).

Note: Threading an adjusting hex bolt in

will force that part of the wheel forward.

Conversely, threading an adjusting hex bolt

out will pull that wheel section to the rear of

the machine when the locking hex bolt is re-

tightened.

3. Re-tighten the locking hex bolts and jam nuts

to secure the settings of the adjusting hex

bolts.

4. Re-check the wheels for alignment and repeat

the steps above if necessary.

5. Re-install the table and check its alignment

with the blade

.

Figure 53. Checking table alignment with the

blade.