G8297/G8298/G8299 Air Compressors

-9-

SECTION 4: OPERATIONS

The pump produces compressed air which goes

into the air tanks through the delivery pipe and

the check valve. When the air pressure arrives at

the factory pre-set level of 135 PSI, the pressure

switch shuts off the electrical current to the axial

electric pump. At the time it shuts off, it dis-

charges the air held in the pump cylinder to the

delivery pipe. This allows the pump to be depres-

surized so it can easily restart. When the pres-

sure in the air tanks falls below the minimum fac-

tory set pressure of 105 PSI, the pump cycles

again to build the pressure back up. The pressure

switch is supplied with a discharge valve with

delayed closing, which reduces the strain on the

pump and the motor during startup.

The compressor is operating correctly when there

is a bleed of air every time the motor is switched

off. You will notice an audible air discharge each

time the pump motor stops. On these compres-

sors, the pump will cycle first to minimize the

amperage draw and will bleed off air through the

cold-start valve. The valve will stay open until

approximately 20 PSI is reached in the air tanks

at which time it closes to allow full pressurization

of the tanks.

For the G8299 with the dual motors, both motors

can be started simultaneously for rapid pressur-

ization. As with the G8298, the 2.5 HP pump is fit-

ted with a cold-start valve which will stay open

until approximately 20 PSI is reached in the

tanks. This will allow the compressor to lubricate

properly without straining the motor and pump.

Depending on the volume of the air usage, it is

often adequate to recharge the system during

operation using only the 2 HP pump taking

advantage of its lower RPM and quieter opera-

tion.

General

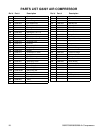

Fig 3. Pressure safety relief valve.

All of the compressors are equipped with a 150

PSI safety relief valve which will discharge air

from the tanks if for any reason they should

become over-pressured. See Figure 3. These

are preset valves and are not adjustable.

Relief Valve

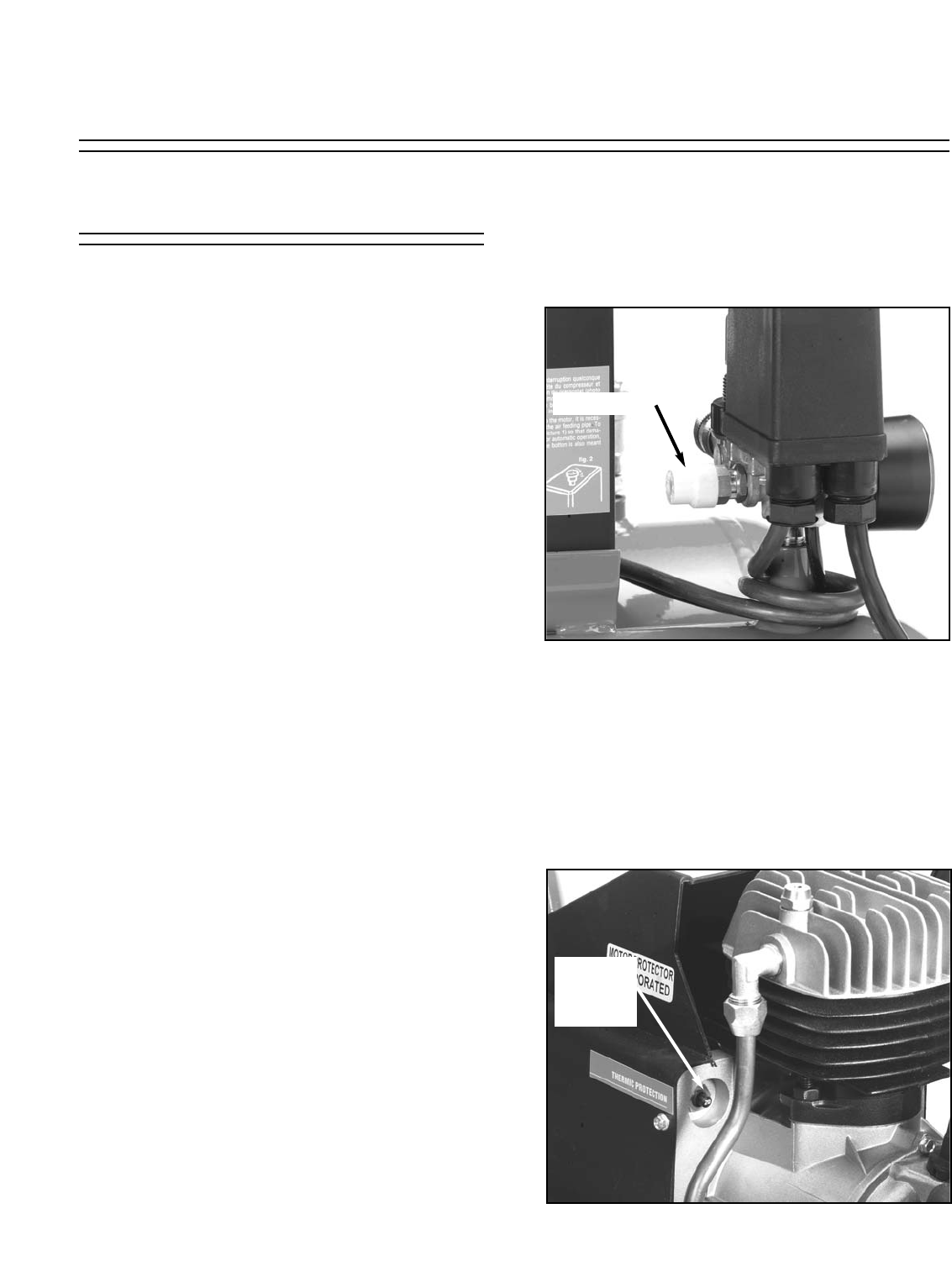

Fig 4. Thermal protection typical placement.

Thermal

Overload

Switch

These compressors are also equipped with ther-

mal overload breakers which will trip if there is

excessive load on the motors which causes a

heat buildup. In the event the breaker shuts the

compressor down, wait a few minutes for the unit

to cool down, then press the reset button shown

in Figure 4.