-20- Extreme Duty Planers

V-Belt

Avoid getting grease or oil on the V-belts or pul-

leys. Check the V-belts, as part of a monthly

inspection for proper tension and belt condition.

Cracking and glazing could result in belt failure.

Replace the belt if such conditions appear.

To loosen/tighten belt tension:

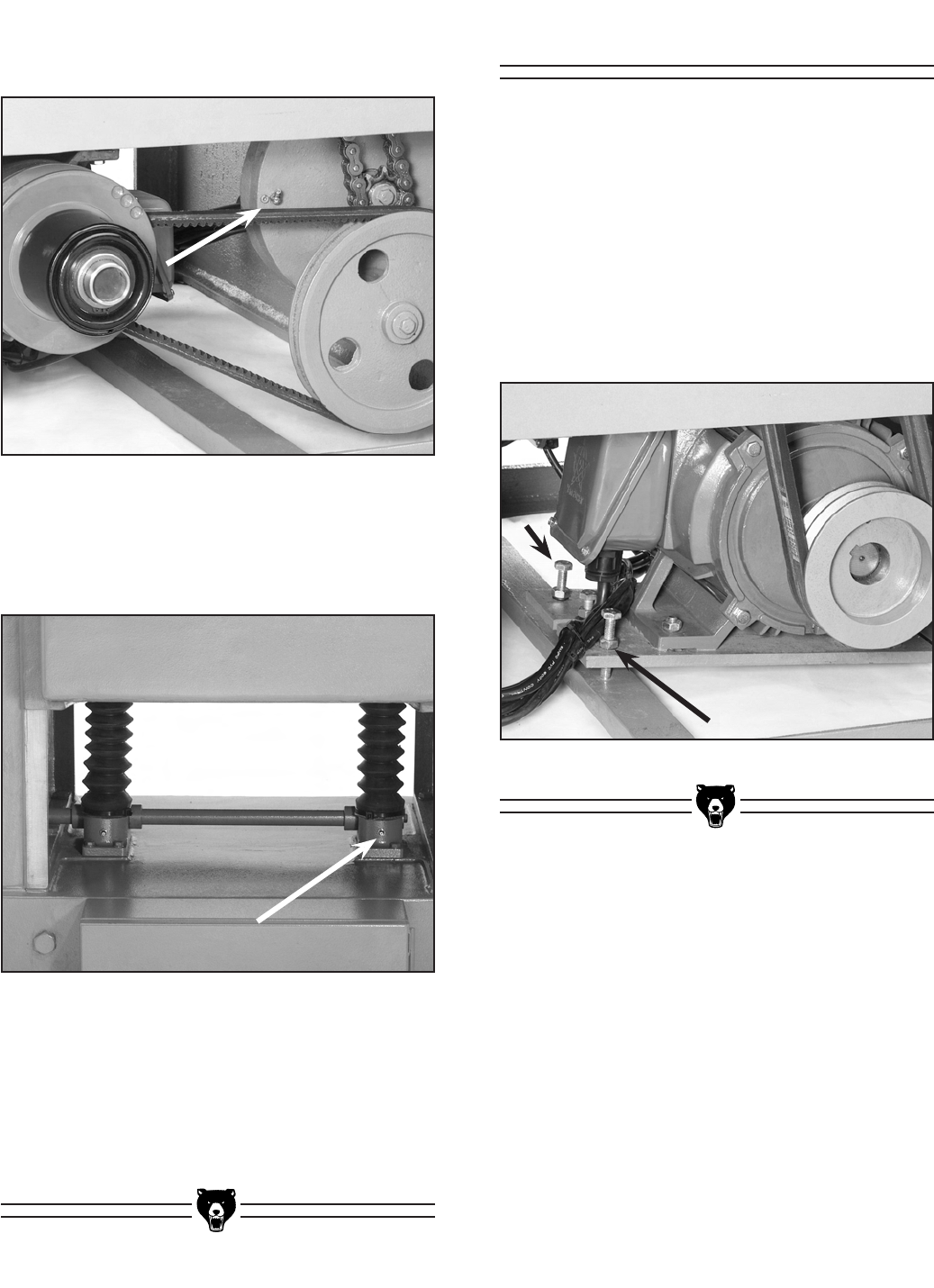

1. Thread in the motor mount adjustment bolts

(Figure 23) to loosen the V-belt. Unthread

the

adjustment bolts to tighten the V-belt.

Figure 21. Transmission box grease fitting.

Figure 22. Table lifting gear grease fittings.

Figure 23. Motor mount adjustment bolts.

2. Transmission Box — Lubricate after every

12 hours of continuous use. See Figure 21

for

location.

3. Table Lifting Gears — Once a week for

heavy use; once a month for moderate use.

See Figure

22 for locations.

4. Chain — Clean and regrease as determined

by visible inspection for dust or grime in the

chain grease.

Always wipe off excess grease from all loca-

tions

after lubricating!