G9742 5" x 6" Metal Cutting Bandsaw

-23-

AZii]ZWaVYZgZVX][jaaheZZYWZ[dgZZc\V\"

^c\i]Zldg`e^ZXZ#CZkZghiVgiVXjil^i]i]Z

WaVYZ ^c XdciVXi l^i] i]Z ldg`e^ZXZ hZZ

Figure 27#

8]^eh h]djaY WZ XjgaZY VcY h^akZgn# >[ i]Z

X]^ehVgZi]^cVcYedlYZga^`Z!^cXgZVhZndjg

[ZZYgViZ#

7jgcZYX]^eh^cY^XViZVcZZYidgZYjXZndjg

WaVYZheZZY#

LV^ijci^ai]ZWaVYZ]VhXdbeaZiZanhideeZY

WZ[dgZgZbdk^c\i]Zldg`e^ZXZ[gdbi]Zk^hZ!

VcYVkd^YidjX]^c\i]ZXjiZcY·^iXdjaYWZ

kZgn]di

Hjeedgiadc\e^ZXZhhdi]Znldci[Vaal]Zc

Xji! VcY[aV\i]Z ZcYid VaZgieVhhZgh"Wn d[

ediZci^VaYVc\Zg#

6Y_jhii]ZWaVYZ\j^YZhVhXadhZVhedhh^WaZ

id i]Z ldg`e^ZXZ id b^c^b^oZ h^YZ"id"h^YZ

WaVYZbdkZbZci#

JhZXddaVcil]Zcedhh^WaZid^cXgZVhZWaVYZ

a^[Z#

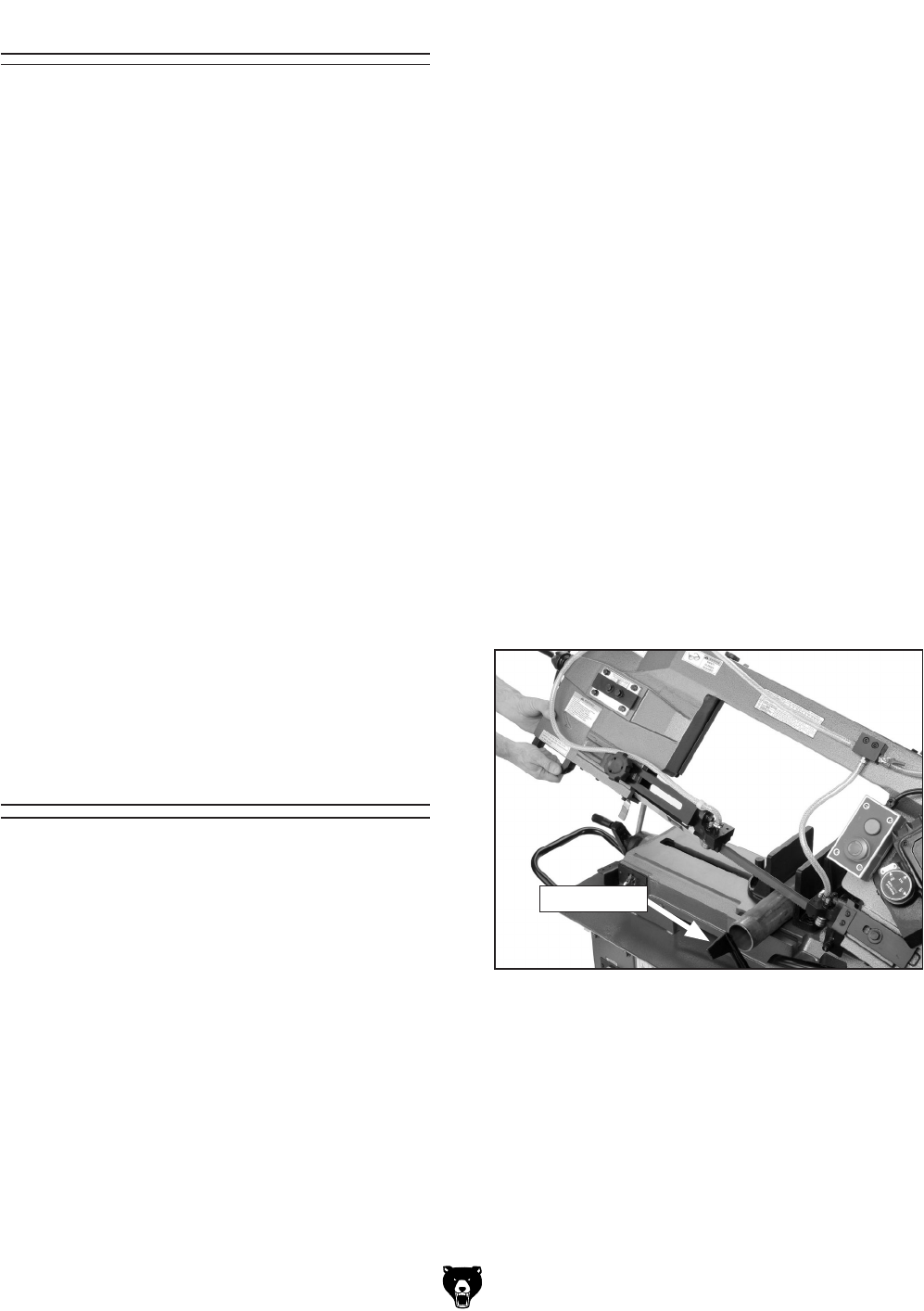

Figure 27#Ine^XVaegdeZghiVgi^c\edh^i^dc#

Ldg`Hide

Blade Tension

Proper blade tension is essential to long blade life,

straight cuts, and efficient cutting.

Two major signs that you do not have proper

blade tension are: 1) the blade stalls in the cut and

slips on the wheels, and 2) the blade frequently

breaks from being too tight.

To tension the blade on the bandsaw:

1. Make sure the blade is tracking properly.

2. UNPLUG THE BANDSAW!

3. Slide the blade guides as far apart as they

will go, then tighten them down again.

4. Turn the tension knob clockwise to tighten

the blade, or counterclockwise to loosen the

blade.

Note: To fine tune blade tension, use a

blade tensioning gauge, like the one found in

SECTION 5: ACCESSORIES on Page 24.

Please follow the instructions included with

your gauge and the blade manufacturer's

recommendations on blade tension.

Operation Tips

I]Z[daadl^c\i^ehl^aa]ZaendjhV[ZanVcYZ[[ZX"

i^kZandeZgViZndjgWVcYhVl!VcY]Zaendj\Zii]Z

bVm^bjba^[Zdjid[ndjghVlWaVYZh#

Tips for horizontal cutting:

JhZi]Zldg`hideidfj^X`anVcYVXXjgViZan

Xji bjai^eaZ e^ZXZh d[ hidX` id i]Z hVbZ

aZc\i]#

8aVbei]ZbViZg^Va[^gban^ci]Zk^hZ_Vlhid

ZchjgZ V higV^\]i Xji i]gdj\] i]Z bViZg^Va!

VcY jhZ i]Zedh^i^kZ adX` idheZZY egdYjX"

i^dc#