Ultimate Series Jointers -19-

SECTION 6: OPERATIONS

Once assembly is complete and adjustments are

done to your satisfaction, you are ready to test

run the machine.

Turn on the power supply at the main panel.

Press the START button. Make sure that your fin-

ger is poised on the STOP button, just in case

there’s a problem. The jointer should run smooth-

ly, with little or no vibration or rubbing noises.

Strange or unnatural noises should be investigat-

ed and corrected before operating the machine

further.

If you cannot easily locate the source of an

unusual noise or vibration, contact our service

department for help.

Test Run

Stock Inspection

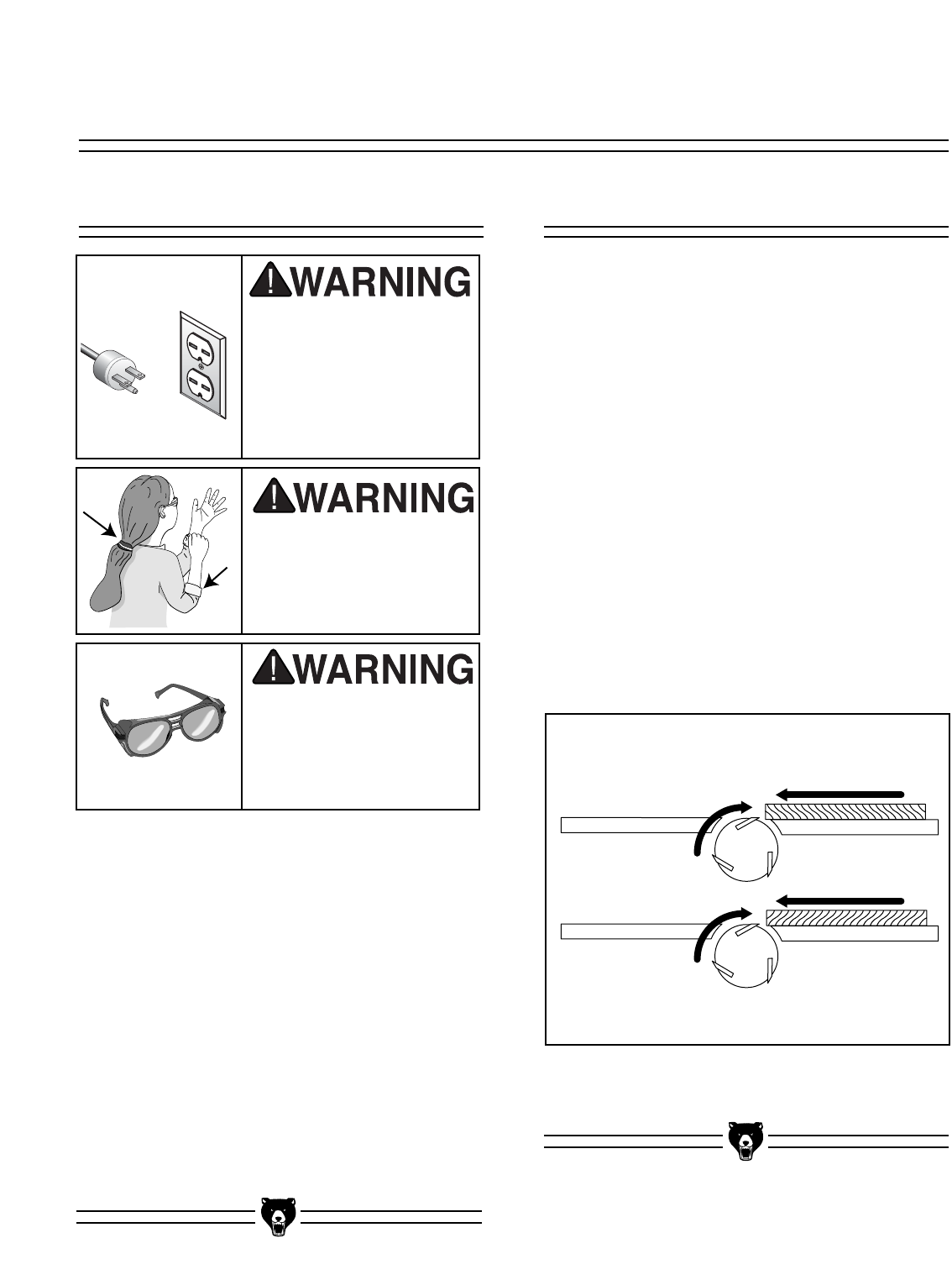

Figure 18. Correct and incorrect grain align-

ment to cutterhead.

OUTFEED TABLE

ROTATION

INFEED TABLE

FEED DIRECTION

OUTFEED TABLE

ROTATION

INFEED TABLE

FEED DIRECTION

If the stock has large or loose knots, consider

finding another workpiece. Knots in a workpiece

can be dangerous to the operator, as well as

destructive to equipment.

When jointing, always cut with the grain rather

than against it. Cutting against the grain (going

against the pattern of the wood’s growth rings)

chips the wood instead of cutting it, making the

workpiece rough and irregular. Look at the side of

your board. If the direction of the grain structure

facing the cutterhead runs toward the cutterhead

as it sits on the infeed table, your cut will be with

the grain as shown in Figure 18.

Occasionally, you will find woods that defy all

rules. In those rare cases, it is best to feed the

workpiece slowly and take several shallow cuts.

A few extra passes will hurt much less than a

ruined workpiece.

Disconnect power to the

machine when perform-

ing any maintenance,

assembly or adjust-

ments. Failure to do this

may result in serious

personal injury.

!

Keep loose clothing

rolled up and out of the

way of machinery and

keep hair pulled back.

Wear safety glasses

during the entire opera-

tion process. Failure to

comply may result in

serious personal injury.

CORRECT

INCORRECT