G9908 3 Function Hammer Drill

-5-

OPERATION INSTRUCTIONS

Disassembly and improper reassem-

bly of this device can result in electri-

cal shock danger. Always have this

device serviced by a qualified electri-

cal repair technician. Serious injury

will result.

Inserting And Changing Bits

Clean and lightly oil the selected bit before

inserting. Pull back the locking sleeve and

slide bit into hammer drill. Twist bit with

slight inward pressure until it moves further

into the hammer drill. Release locking

sleeve and make sure that bit is secured in

place and will not come out by hand. For

removal, pull back locking sleeve and slide

bit straight out of hammer drill.

Operation

1. The hammer drill can be started and

stopped by simply pressing and releasing

the trigger switch.

2. For safety reasons, you should always

use the auxiliary handle during use. If the

hammer drill locks up, the auxiliary handle

will help you maintain control and

decrease your chances of injury. To adjust

the auxiliary handle, twist it counterclock-

wise until it is loose enough to position

where you need it, then twist clockwise to

tighten.

3. Setting the depth gauge rod can be

done by loosening the auxiliary handle and

inserting the rod into the hole on the auxil-

iary handle near the body of the hammer

drill. Tighten handle when your desired

length is achieved.

4. The dust protection cap can be fitted on

the bottom end of the bits before you insert

them into the hammer drill. This will help

prevent to a large extent the entry of

drilling dust. The hollow side of the dust-

cap should face body of the hammer drill.

5. It is important that you don’t apply too

much pressure to the hammer drill during

operation. Excessive force puts unneces-

sary stress on the motor and increases

likelyhood of getting hurt. If speed drops

suddenly during use, decrease pressure

immediately.

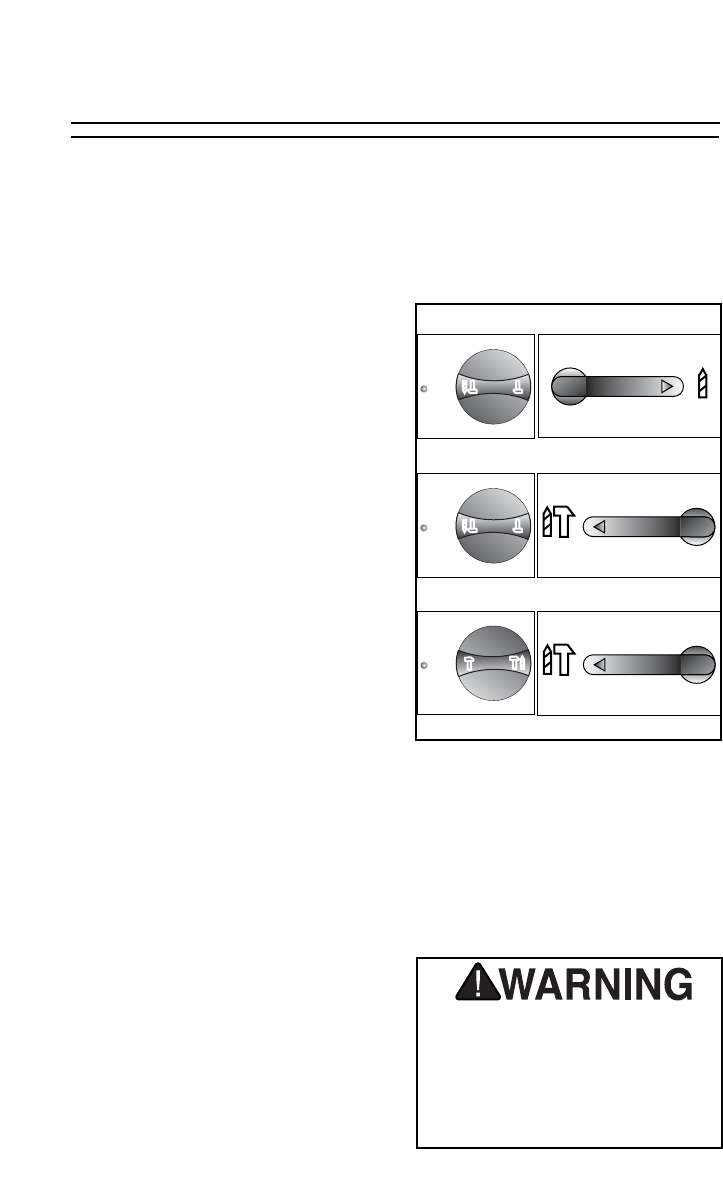

Mode Selector Switch

You can achieve the three functions of the

hammer drill by selecting the various com-

binations of front and back switches. Refer

to Figure 2 for more details.

Drill Mode

Power Chisel Mode

Hammer Drill Mode

Fig 2. Functions of Hammer Drill

Maintenance

It is important that you always keep the

device and ventilation slots clean. Aside

from lubricating bits before insertion, all

other repairs or maintenance to the inter-

nal parts of the tool should be done by a

qualified service technician.