G1066/G1066Z/G1079 Drum Sander -21-

Conveyor Belt

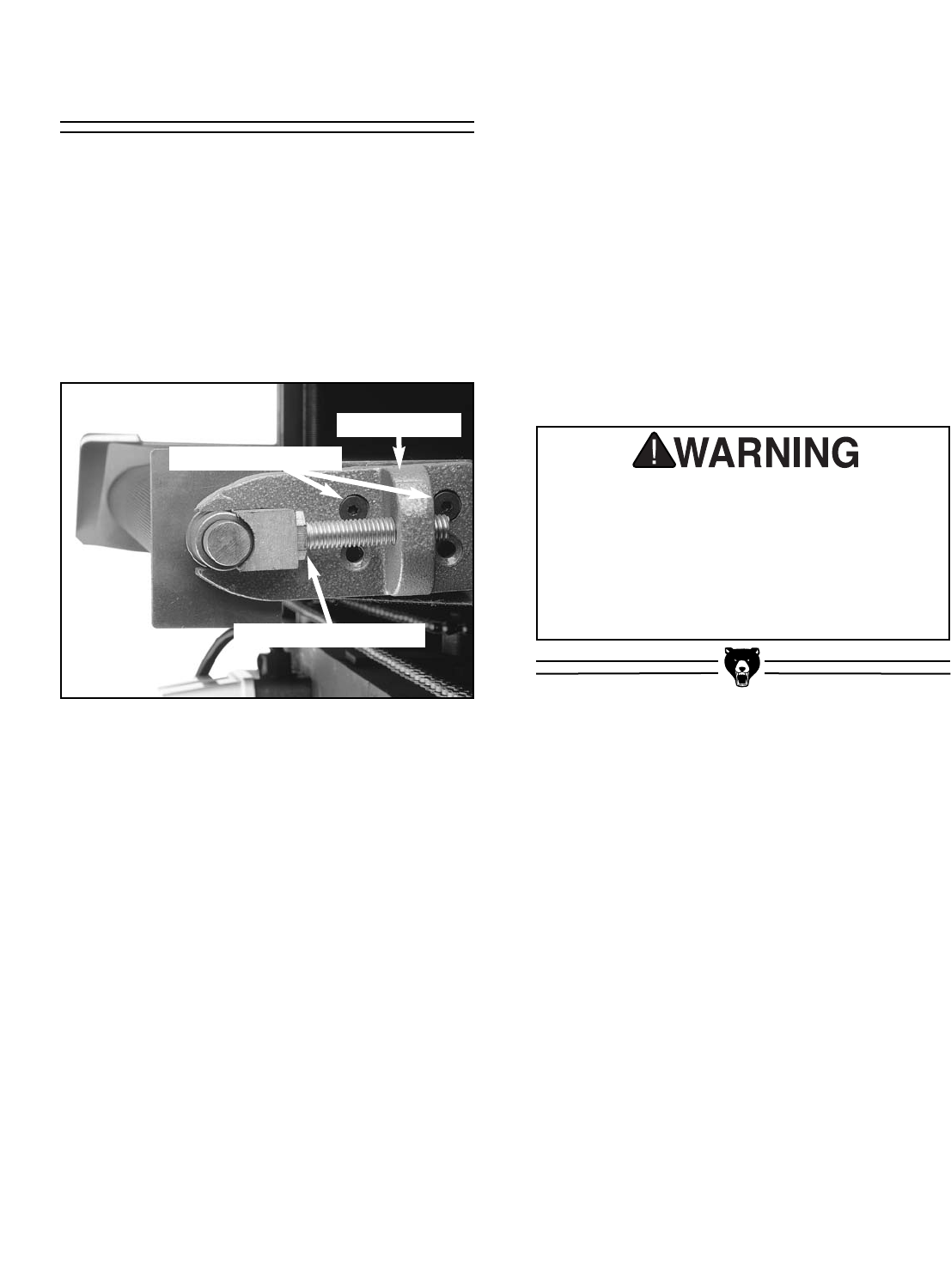

The conveyor belt tension and tracking adjust-

ments are controlled by the adjustment bolts

located at each end of the front and rear convey-

or rollers. If the conveyor belt is too loose or

tracks off to one side, adjust as follows:

1. If the conveyor belt is slipping, turn both

infeed adjustment bolts counter-clockwise.

See Figure 16.

Figure 16. Location of conveyor adjustments.

Roller Bracket

Allen

®

Head Screws

Roller Adjustment Bolt

Always make adjustments at the infeed end

to avoid re-adjusting conveyor drive chain.

Conveyor belt tracking adjustments must be

made while the conveyor belt is running.

Use extreme care to ensure that clothing,

hair or jewelry is kept safely away from mov-

ing parts.

2. If the conveyor belt tracks toward the right

side, turn the adjustment bolt located at the

infeed right corner. Turning this bolt counter-

clockwise will make the sanding belt move to

the left.

3. After you have made the adjustment, run the

machine for approximately 15 minutes to

observe the tracking adjustment you made.

Be patient, the belt tracks slow.

4. If the conveyor belt tracks too far to the left,

loosen the adjustment bolt. Turning this bolt

clockwise will move the sanding belt to the

right.