H7945/H7946/H7995 26° Angle Nailer

-12-

Replacing

Pistons/O-Rings

If you need to replace piston parts in your

nailer, you can purchase a piston repair kit

from Grizzly: call 1-800-523-4777.

The Piston Repair Kit part number for

Model H7945 is PH7945090; the Piston

Repair Kit part number for Model H7946

is PH7946090; the Piston Repair Kit part

number for Model H7995 is H7995090.

Refer to the parts breakdown during this

procedure to identify parts and their loca-

tions inside the nailer.

4. Push the top of the piston down with

your finger as far as it will go; this will

push the piston driver into the nose of

the nailer.

5. Insert a stiff rod or wire of the same

diameter as your nails into the dis-

charge area of the nose and use it

to push the piston driver up until the

piston head clears the top of the cyl-

inder. (Be careful not to scratch the

discharge area or the piston cylinder.)

6. Grip the piston head by hand and

remove the piston assembly from the

cylinder.

7. Clean all metal parts with an auto-

motive grade solvent. Clear all ports

and blow the solvent away with com-

pressed air.

8. Replace any part that shows damage

of heavy wear. Relubricate the tool.

9. Apply a thin film of the nailer lubricat-

ing oil on the new O-ring and place

it on the new piston. Install any other

parts included in the piston repair kit.

10. Insert the new piston in the cylinder.

Make sure that the grooves on the

piston driver align with those in the set

plate at the bottom of the cylinder.

Note: DO NOT force the piston into

the cylinder! If the piston is not easily

inserted, double-check the alignment

of the piston driver with the grooves on

the set plate.

12. Put the cylinder seal back on the top

rim of the cylinder.

13. Make sure that the cap gasket is in

place, then secure the cap to the nailer

body by tightening the 4 cap screws.

To replace a piston and O-ring(s):

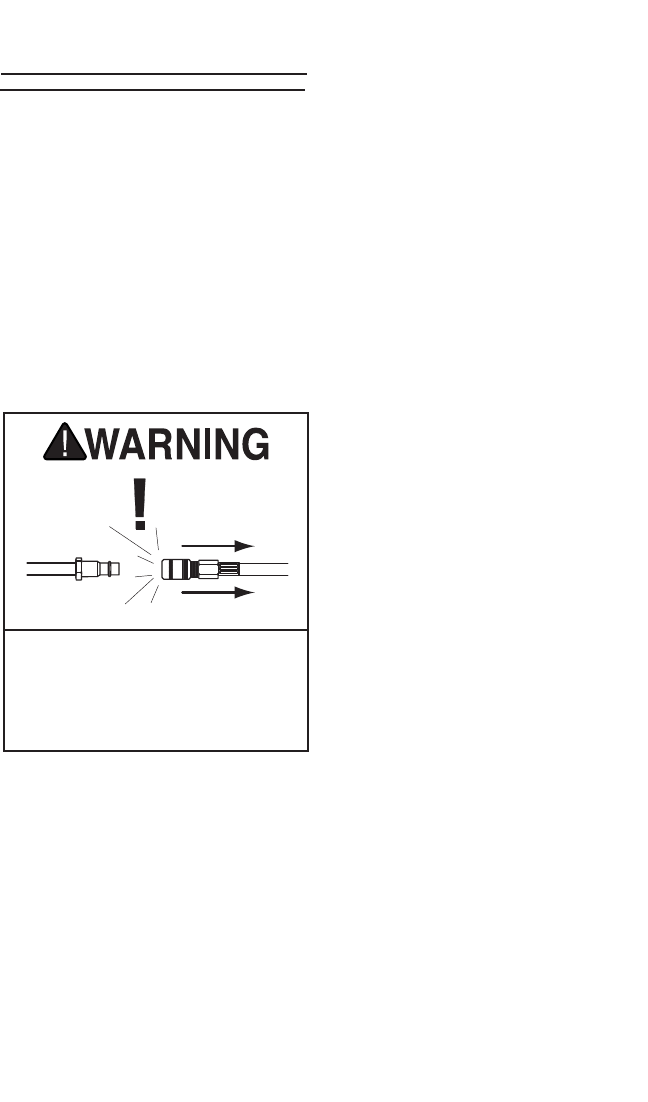

1. DISCONNECT NAILER FROM THE

AIR SUPPLY!

2. Remove all nails from the magazine.

3. Remove the four screws that secure

the nailer cap, then remove the cylin-

der cap and cylinder seal.

Always disconnect the air supply

from the nailer whenever servicing!

During maintenance, a nailer con-

nected to air may fire accidentally,

causing serious personal injury!