Page 11For technical questions, please call 1-800-444-3353.SKU 68341

TO PREVENT SERIOUS

INJURY FROM

ACCIDENTAL OPERATION:

Turn the Power Switch off and unplug the

Router before performing any inspection,

maintenance, or cleaning procedures.

TO PREVENT SERIOUS INJURY

FROM TOOL FAILURE:

Do not use damaged equipment. If abnormal

noise or vibration occurs, have the

problem corrected before further use.

Cleaning, Maintenance,

and Lubrication

1. BEFORE EACH USE, inspect the general condition

of the tool. Check for loose hardware, misalignment

or binding of moving parts, cracked or broken

parts, damaged electrical wiring, and any other

condition that may affect its safe operation.

2. AFTER USE, wipe external surfaces

of the tool with clean cloth.

3. Regularly clean all ventilation openings by

periodically brushing with a soft brush and/

or blowing clear with compressed air.

4.

WARNING! If the supply cord of this power

tool is damaged, it must be replaced only by a

qualied service technician.

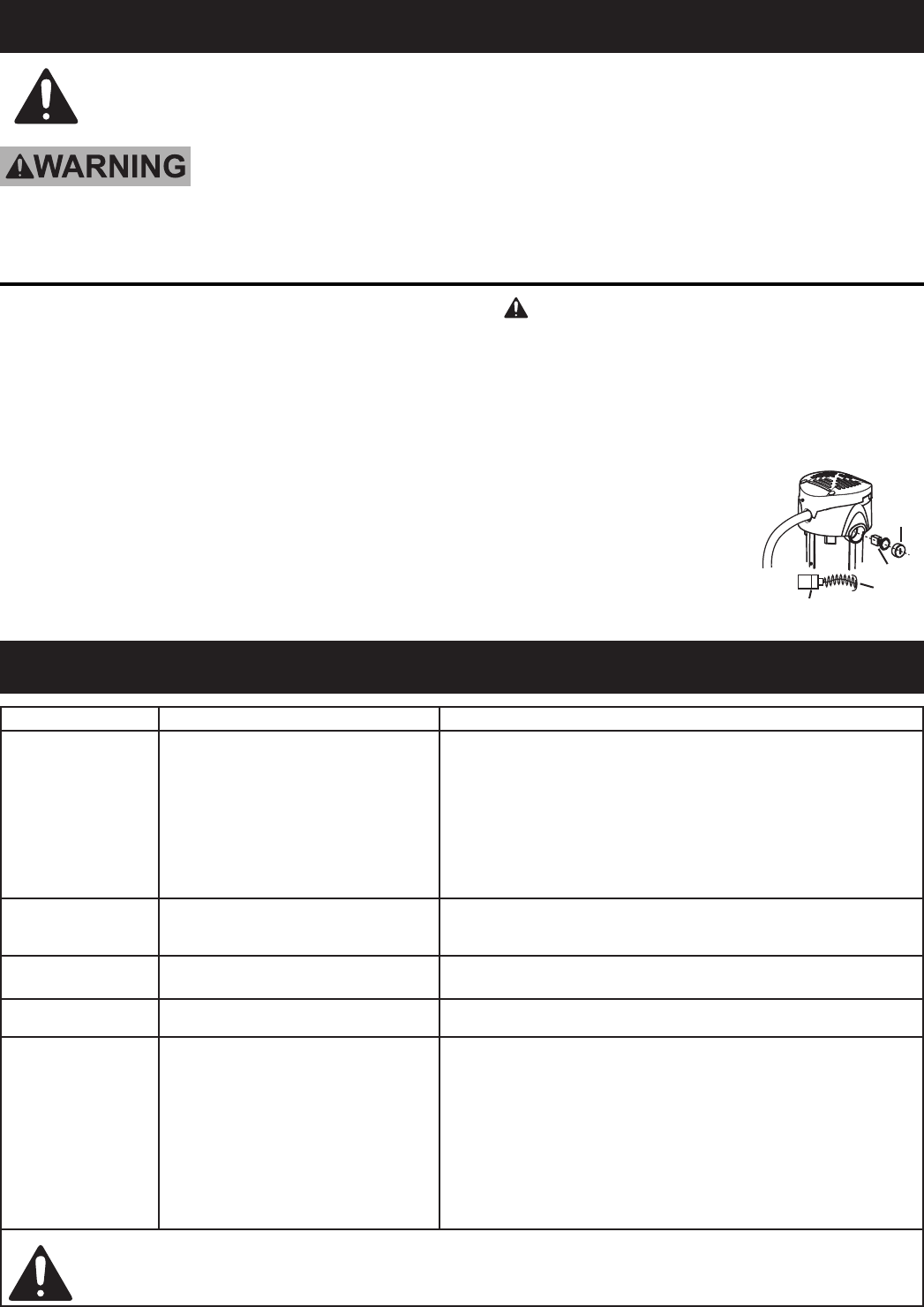

Replacing Carbon Brushes

Remove and check the Carbon Brushes regularly.

Replace when they wear down to the limit mark on

the carbon. Replace both

brushes at the same time.

To replace: Remove the Brush

Caps and old brushes, then

insert the new brushes and

secure the caps in place.

Carbon

Brush

(18)Limit mark

Brush

Cap

(15)

Maintenance and Servicing

Procedures not specically explained

in this manual must be performed

only by a qualied technician.

Troubleshooting

Problem Possible Causes Likely Solutions

Tool will not start. 1. Cord not connected.

2. No power at outlet.

3. Tool’s thermal reset breaker

tripped (if equipped).

4. Internal damage or wear. (Carbon

brushes or switch, for example.)

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered, turn off tool

and check circuit breaker. If breaker is tripped, make sure

circuit is right capacity for tool and circuit has no other loads.

3. Turn off tool and allow to cool. Press reset button on tool.

4. Have technician service tool.

Tool operates slowly. Extension cord too long or

wire size too small.

Eliminate use of extension cord. If an extension cord is

needed, use shorter/heavier gauge cord. See Extension

Cords in Grounding section on page 5.

Performance

decreases over time.

1. Accessory dull or damaged.

2. Carbon brushes worn or damaged.

1. Keep cutting accessories sharp. Replace as needed.

2. Have qualied technician replace brushes.

Excessive noise

or rattling.

Internal damage or wear. (Carbon

brushes or bearings, for example.)

Have technician service tool.

Overheating. 1. Forcing tool to work too fast.

2. Accessory misaligned.

3. Accessory dull or damaged.

4. Blocked motor housing vents.

5. Motor being strained by long or

small diameter extension cord.

1. Allow tool to work at its own rate.

2. Check and correct accessory to fence and/or table alignment.

3. Keep cutting accessories sharp. Replace as needed.

4. Wear ANSI-approved safety goggles and

NIOSH-approved dust mask/respirator while blowing

dust out of motor using compressed air.

5. Eliminate use of extension cord. If an extension cord is needed,

use one with the proper diameter for its length and load. See

Extension Cords in Grounding section on page 5.

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power

supply before service.