Page 6SKU 92353 For technical questions, please call 1-800-444-3353

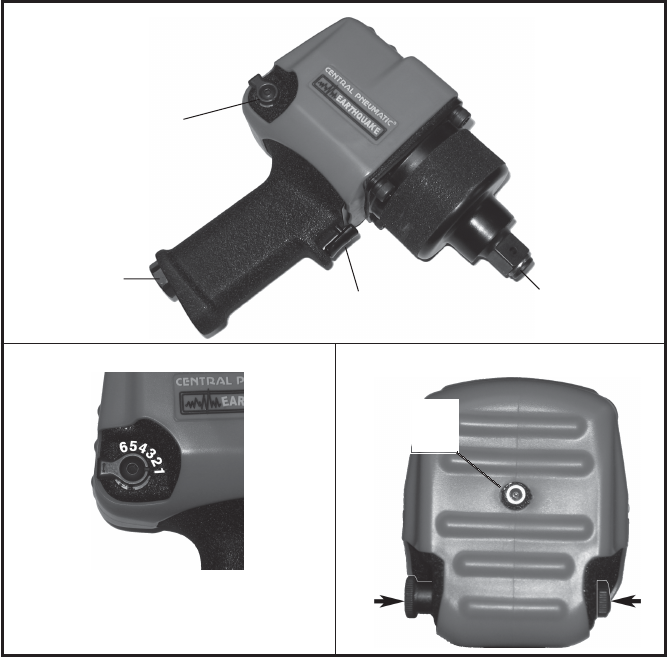

FIGURE 2

FIGURE 3

Turn the Regulator Knob (15) to a higher num-

ber for more air flow and more power.

Turn the Knob to a lower number for less power.

In the illustration above it is set to position 1.

1. Make sure your Impact Wrench is disconnected from the air hose before attempting any

maintenance.

2. Wipe the Impact Wrench down with a lint free cloth after each use.

3. Make sure the Anvil (39) is clear of dirt or debris. If possible, spray it with compressed

air before each use.

4. Annually, or more often if used on a daily basis, use a grease gun (not included), to

inject grease into the Grease Fitting (12). See FIGURE 3.

5. If you do not use an inline oiler/filter system, lubricate the tool daily by holding it so that

the Inlet (8) is facing up. Squeeze the Trigger (2), and place one or two drops of oil into

the Inlet (8). Squeezing the Trigger (2) allows the oil to circulate in the motor.

Maintenance

Regulator

Knob (15)

Trigger (2) Anvil (39)

Inlet (8)

FIGURE 1

Grease

Fitting

(12)

Forward Reverse