Page 4 HRO-ST3131 Mar 8, 2004

GAS / HYDRAULIC POWERED AIRLESS

SPRAY PUMPS.

Gas / Hydraulic powered airless spray equipment is an

industrial paint sprayer which uses a gas engine to drive a

hydraulic pump which in turns produces hydraulic pres-

sure. This pump delivers pressure fluid to a hydraulic mo-

tor which drives a high pressure airless piston pump. All

of these components make this unit a heavy duty portable

airless sprayer which is capable of high volume and high

production able to pump and spray light to very high vis-

cous materials. Airless spray is fast, economical and

needs no atomizing air.

Airless spray systems use a high pressure pump

to supply fluid to the spray tip, where it is atomized

by the pressure and sprayed onto a desired surface.

Control of the atomizing pressure is done by regulating

the hydraulic fluid pressure in the hydraulic pump.

The spray is controlled by triggering a hand gun,

or activating the controls of an automated system.

The spray pattern and flow rate is controlled by

choosing the spray tip best suited to your needs.

GENERAL SAFETY WARNING

•

High pressure spray can cause serious injury.

•

Because of the high pressure and velocity of the fluid

being atomized, paint, solvent or other fluids could

penetrate through your skin, into your body or eyes.

•

Never point the spray gun at yourself or anyone else.

•

Never put your hands, fingers or any part of the

body over the spray tip/nozzle.

•

Even after you shut off the pump, there is still high

pressure in the system, You must always follow the

“PRESSURE RELIEF PROCEDURE”

before ser-

vicing, or removal of the spray tip/nozzle.

SAFETY WARNING!

•

Use of this high-pressure equipment could result in serious injury and is for

professional use only!

•

You must operate this equipment only after the instruction manual is clearly understood.

•

Workman and assistant must always wear protective eyewear, gloves, clothing,

and respirators as recommended by the material manufacturer.

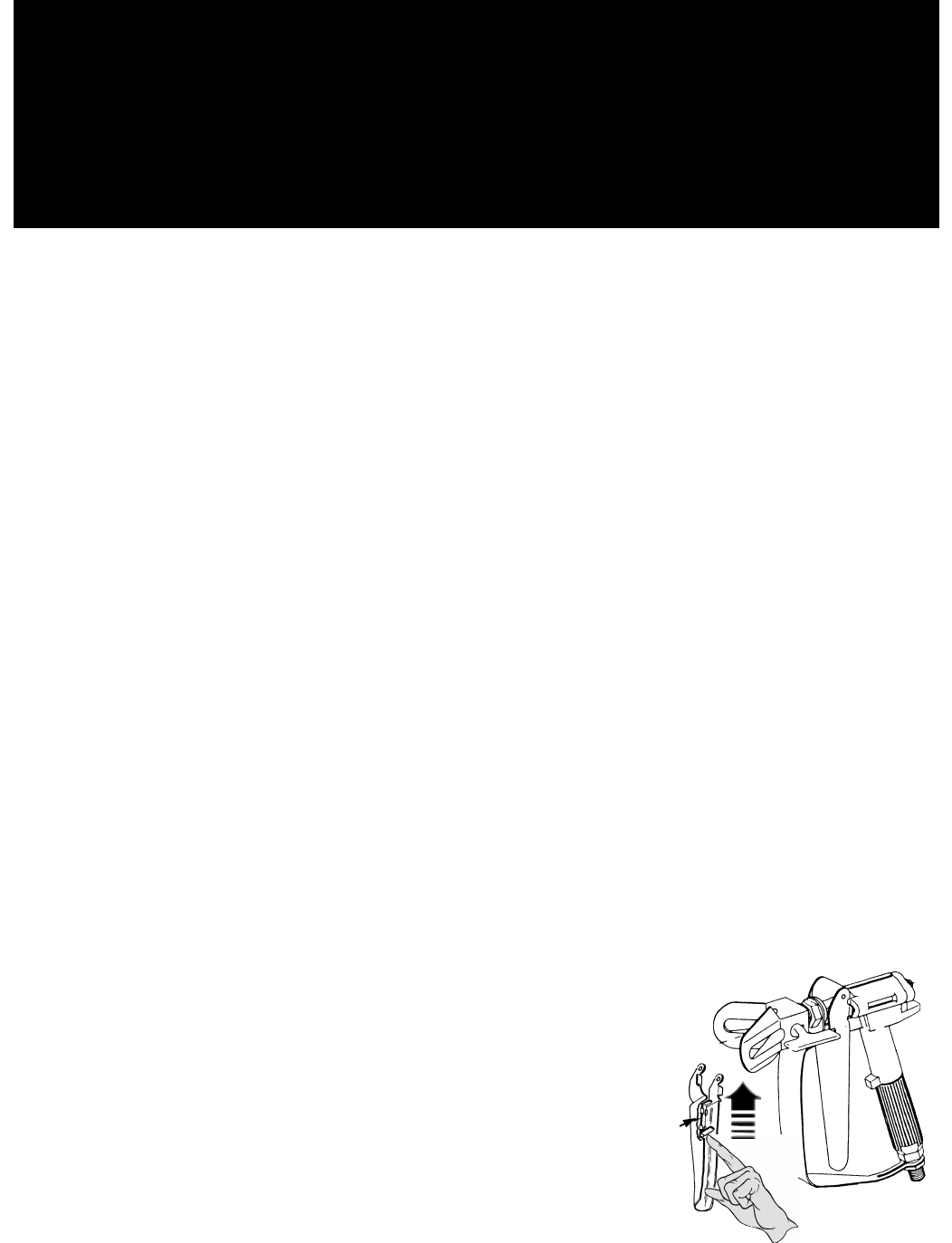

SPRAY GUN SAFETY WARNING

•

Never

point the gun at yourself or anyone

else: This can result in serious injury.

•

Safety latch:

Engage trigger safety latch in

the closed or “LOCK” Position see FIG 1,

whenever you stop spraying, even for a mo-

ment. Failure to engage trigger safety latch

can result in serious injury.

•

Trigger safety guard:

This prevents the

gun from triggering accidentally when it is

dropped or bumped. You must not operate

without the trigger safety guard.

•

When

cleaning or changing the tips use ex-

treme caution and follow the “

PRESSURE

RELIEF PROCEDURE”

then remove the

spray tip.

•

Aim

the spray gun into a grounded metal

pail using the lowest pressure possible,

then trigger the spray gun.

•

If

the fluid sprayed is not diffused into a

irregular stream, replace the diffuser at once.

•

If

the spray tip clogs while spraying, engage

trigger safety latch in “SAFE” position

immediately.

•

Never

wipe off around the spray tip until

pressure is fully relieved and the trigger

safety latch in “SAFE” position.

Trigger safety lock

Push up to engage

lock

Fig 1