— 10 —

English

MAX.

MIN.

3. Extension cord

When the work area is far away from the power

source, use an extension cord of sufficient thickness

and rated capacity (refer page 6). The extension cord

should be kept as short as practicable.

WARNING:Damaged cord must be replaced or

repaired.

4. Confirm the power receptacle

If the power receptacle only loosely accepts the plug,

the receptacle must be repaired. Contact the nearest

electric store for repair service.

If such a faulty receptacle is used, may cause

overheating, resulting in a serious hazard.

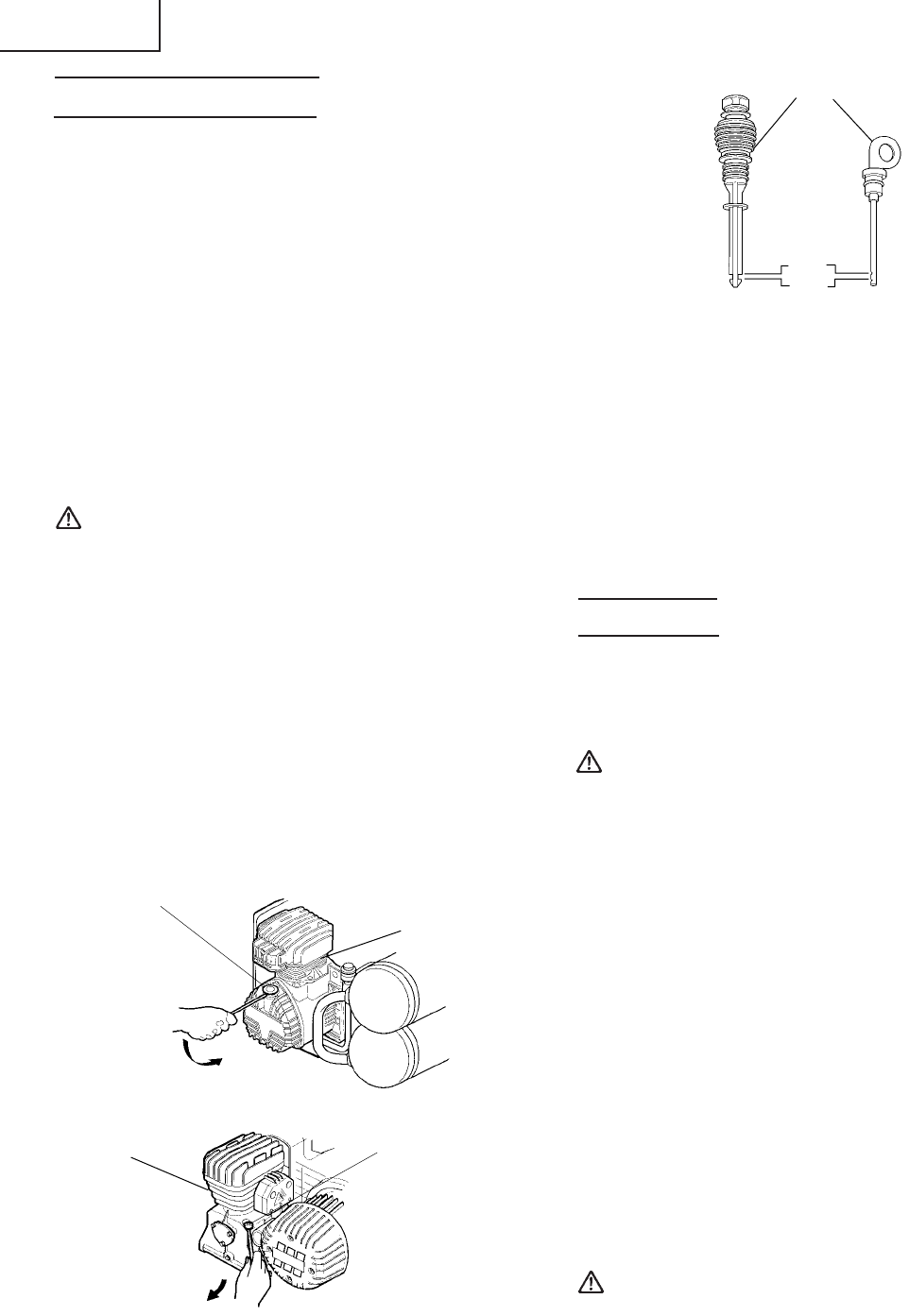

5. Dipstick insertion and oil level check

(If your compressor is EC6C this step is not

necessary.)

Use a screwdriver or similar tool to remove the plastic

cap on the lower part of the cylinder (Fig. 2).

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power source requirements specified on the

product nameplate.

2. Power switch

Ensure that the knob of the pressure switch is in the

“OFF” position. If the plug is connected to a

receptacle while the knob is in the “AUTO” position,

the compressor will start operating immediately and

can cause serious injury.

6. Air coupler installation

Screw in the air coupler to the joint (Refer to Fig. 1

and Fig. 4.). The screw size of the joint is 3/8". Use an

air coupler which has the same screw size.

OPERATION

1. Start up

Insert the plug into the receptacle and start the

compressor by turning the knob of the pressure

switch, to “AUTO”. (Refer to Fig. 1 and Fig. 4).

WARNING: Do not stop or start the compressor

by use of the plug. Always use

“AUTO/OFF” knob located on the

pressure switch.

The operation of the compressor is automatic and is

controlled by the pressure switch which stops it when

the pressure in the air-tank reaches the maximum

level and restart it when the air pressure drops during

use to the restart level.

The motor of the compressor is fitted with a thermal

protection inside-the wrap, which stops the

compressor when the temperature is too high. Should

this be tripped, the compressor will restart automati-

cally after 15–20 minutes.

2. Adjustment of working pressure

Unlock the knob of the pressure reducer pulling it up,

adjust the pressure to the required level by turning the

knob clockwise to increase and counterclockwise to

decrease.

A pressure gauge is provided to know when the

required pressure is reached, lock the knob by

pushing it down firmly (Fig. 4).

Fig. 3

When the oil volume is insufficient, refer to the section

“Oil change-oil topping off” on page 12 for a descrip-

tion of how to supply the oil.

Fig. 2

Insert the accessory dipstick all the way to the bottom.

Remove the dipstick and make sure the oil level is

within the range of the dipstick notches (Fig. 3).

(EC16)

WARNING: Check the manufacturer’s maximum

pressure rating for nailers, staplers and

accessories. Compressor outlet

pressure must be regulated so as to

never exceed the maximum pressure

rating of the nailers, staplers and

accessories.

EC6B

EC12

(EC16)

()

Dipstick

Plastic cap

EC6B

EC12

()

Plastic cap

Cylinder

Cylinder