- 9 -

English

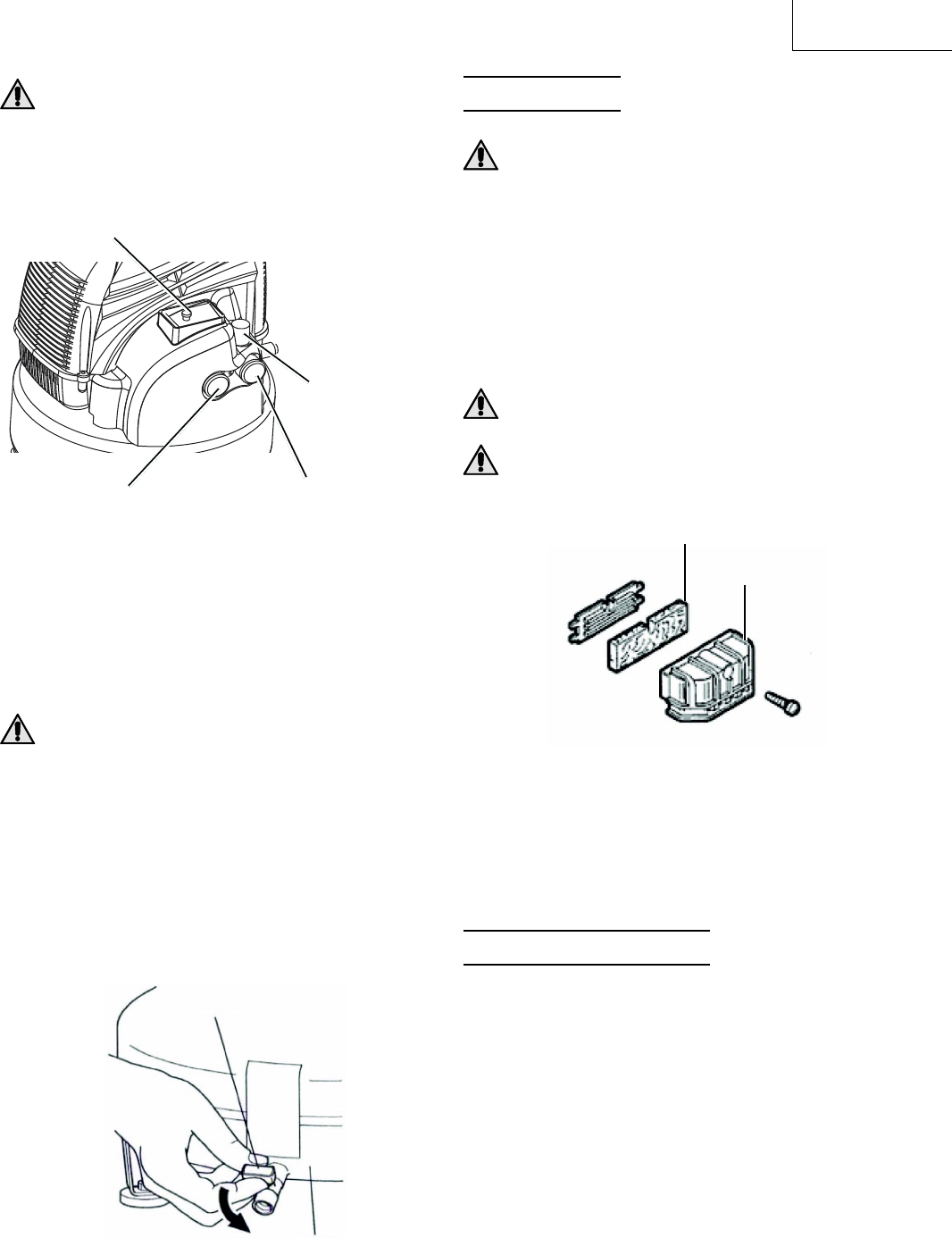

Knob of the

pressure reducer

Pressure gauge (A)

indicates the pressure

in the air tank

Pressure gauge

(B) indicates the

working pressure

Knob of the pressure switch

Drain cock

Intake filter

Filter element

Fig.3

Fig.4

Fig.5

WARNING: Check the manufacturer’s maximum

pressure rating for nailers, staplers and

accessories. Compressor outlet pressure

must be regulated so as to never exceed the

maximum pressure rating of the nailers,

staplers and accessories.

3. Shutdown

(1) Push the knob of the pressure switch to “OFF”

(Refer to Fig. 1 and Fig. 2).

(2) Unplug the plug from power source.

(3) Open the drain cock located at the lower part of the tank

(Fig. 4).

WARNING: Risk of bursting. When the tank gets cor-

roded, there is a risk of breakdown. Water

will condense in the air tank. If not drai-

ned, water will corrode and weaken the air

tank causing a risk of air tank rupture.

Drain tank daily or after 4 hours of use. The

drain contains moisture in the air, abra-

sion particles, rust, etc.. To drain tank

open valve slowly and tilt compressor to

empty accumulated water. Keep face and

eyes away from drain cock.

MAINTENANCE

WARNING: Disconnect the compressor from the

power source and remove the compressed

air from the air tank before performing the

maintenance operations. Allow the

compressor to cool before performing the

maintenance operations.

1. Cleaning the intake filter

Remove the intake filter (Refer to Fig. 1) every 50 hours or

once a week and clean the inside of the intake filter and the

filter element with compressed air (Fig. 5). Use a phillips

screwdriver to disassemble intake filter.

WARNING: Never clean filter element with a flammable

liquid or solvent.

CAUTION: Do not operate without the intake filter.

NOTE: Replace the filter element when it becomes dirty.

2. Draining tank

Drain tank daily or after 4 hours of use. Open drain

cock and tilt compressor to empty accumulated

water (Refer to Fig. 4).

SERVICE AND REPAIRS

All quality compressors will eventually require servicing or

replacement of parts because of wear from normal use.

To assure that only authorized replacement parts will be used,

all service and repairs must be performed by a HITACHI

AUTHORIZED SERVICE CENTER, only.

NOTE: Specifications are subject to change without any

obligation on the part of the HITACHI.

Tank