3

5. Ensure that the depressed center wheel to be utilized

is the correct type and free of cracks or surface defects.

Also ensure that the depressed center wheel is

properly mounted and the wheel nut is securely

tightened, refer to the section on “Depressed Center

Wheel Assembly”.

6. Conducting a trial run

Ensure that the abrasive products is correctly mounted

and tightened before use and run the tool at no-load

for 30 seconds in a safe position, stop immediately if

there is considerable vibration or if other defects are

detected.

If this condition occurs, check the machine to

determine the cause.

7. Confirm the spindle lock mechanism

Confirm that the spindle lock is disengaged by pushing

push button two or three times before switching the

power tool on (See Fig. 3).

8. Fixing the side handle

Screw the side handle into the gear cover.

PRACTICAL GRINDER APPLICATION

1. Pressure

To prolong the life of the machine and ensure a first

class finish, it is important that the machine should

not be overloaded by applying too much pressure. In

most applications, the weight of the machine alone is

sufficient for effective grinding. Too much pressure

will result in reduced rotational speed, inferior surface

finish, and overloading which could reduce the life of

the machine.

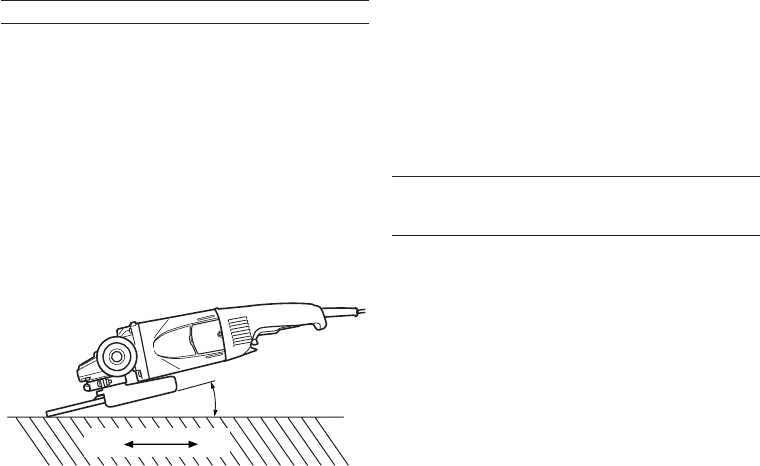

2. Grinding angle

Do not apply the entire surface of the depressed

center wheel to the material to be ground. As shown

in Fig. 2, the machine should be held at an angle of

15° – 30° so that the external edge of the depressed

center wheel contacts the material at an optimum

angle.

Fig. 2

3. To prevent a new depressed center wheel from

digging into the workpiece, initial grinding should be

performed by drawing the grinder across the

workpiece toward the operator (Fig. 2 direction B).

Once the leading edge of the depressed center wheel

is properly abraded, grinding may be conducted in

either direction.

4. Switch operation

Switch ON: Push the locking button forward and

then press the switch lever.

* For continuous use, press the switch

lever. The switch lever is locked by

pushing the locking button forward

once again.

(*Subject to change depending on

area.)

Switch OFF: Press and release the switch lever.

5. Precautions immediately after finishing operation

After switching off the machine, do not put it down

until the depressed center wheel has come to a

complete stop. Apart from avoiding serious accidents,

this precaution will reduce the amount of dust and

swarf sucked into the machine.

CAUTION:

⅜ Check that the work piece is properly supported.

⅜ Ensure that ventilation openings are kept clear when

working in dusty conditions.

If it should become necessary to clear dust, first

disconnect the tool from the mains supply (use non-

metallic objects) and avoid damaging internal parts.

⅜ Ensure that sparks resulting from use do not create a

hazard e.g. do not hit persons, or ignite flammable

substances.

⅜ Always use protective safety glasses and hearing

protectors, use other personal protective equipment

such as gloves, apron and helmet when necessary.

⅜ Always use eye and ear protection.

Other personal protective equipment such as dust

mask, gloves, helmet and apron should be worn

when necessary.

If in doubt, wear the protective equipment.

⅜ When the machine is not use, the power source

should be disconnected.

ASSEMBLING AND DISASSEMBLING THE

DEPRESSED CENTER WHEEL AND OTHER

TOOLS

CAUTION:

Be sure to switch OFF and disconnect the attachment

plug from the receptacle to avoid a serious accident.

1. Assembling (Fig. 3)

(1) Turn the machine upside down so that the spindle is

facing upward.

(2) Mount the wheel washer onto the spindle.

(3) Fit the protruding part of the depressed center wheel

or cutting wheel or diamond wheel onto the wheel

washer.

(4) Screw the wheel nut onto the spindle.

(For diamond wheel assembling, use the wheel nut

with the convex side against the diamond wheel.)

(5) Insert the push button to prevent rotation of the

spindle, and tighten the wheel nut with the accessory

wrench, as shown in Fig. 3.

2. Disassembling

Follow the above procedures in reverse.

CAUTION:

⅜ Comfirm that the depressed center wheel is mounted

firmly.

⅜ Confirm that the push button is disengaged by

pushing push button two or three times before

switching the power tool on.

15 – 30°

AB