English

11

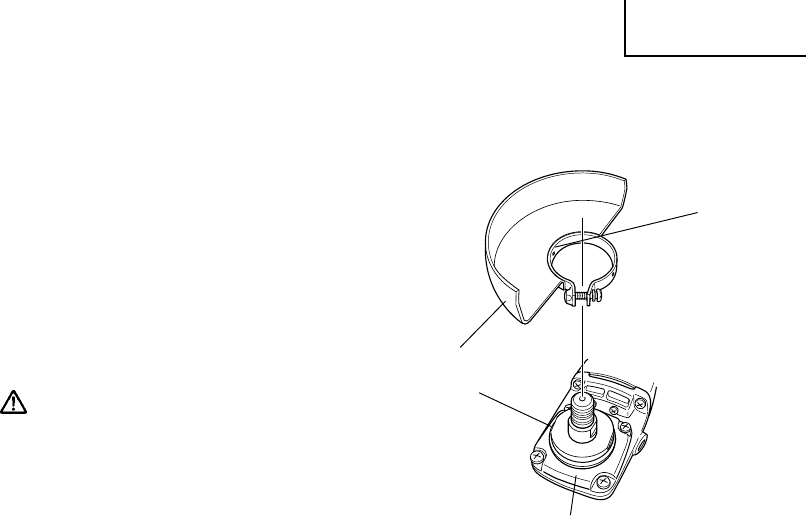

[Installing Wheel Guard]

⅜ Slightly loosen the screw on the wheel

guard.

⅜ Install the wheel-guard-locating pin in

line with the across flats of the packing

gland, turn it to the angle suitable for

operation, and make adjustment.

⅜ After the adjustment, ensure that the

screw is securely tightened on the wheel

guard in order to fix it completely.

WARNING:

If the wheel guard is not attached properly,

a broken wheel may result in and cause

death or serious injury.

7. Thoroughly check that the depressed center

wheel is free of cracks, splits and other

abnomalities before mounting. Make sure it

is firmly clamped and has been properly

mounted. Refer to page 13 of this manual for

Depressed Center Wheel Assembly and

Disassembly

8. Test the grinder before using.

Before actually beginning the grinding work, test the grinder by first clearing the area of

all other personnel. Make sure the wheel guard is in place and that you are wearing eye

protection. Turn the grinder “on”, and make sure the grinder runs smoothly and shows

no abnormalities.

Duration of the trial run is as follows:

When depressed center wheel is replaced .................. 3 minutes or more

When starting daily work .............................................. 1 minute or more

9. Use only properly rated depressed center wheels.

Use only depressed center wheels rated at 13300 RPM or more.

Using a depressed center wheel rated less can lead to wheel disintegration during

operation and cause serious bodily injury.

10.Check the push button.

Make sure that the push button is disengaged by pushing push button two or three times

before turning on the grinder. (Fig. 5)

Fig. 2

Wheel Guard

Locating Pin

Across Flats

Packing Gland

6. Mounting the wheel guard

Be sure to mount the wheel guard at an angle that will protect the operator’s body from

injury by a broken wheel piece.

G12SA2_1-E.E65 8/20/02, 11:50 AM11