English - 27

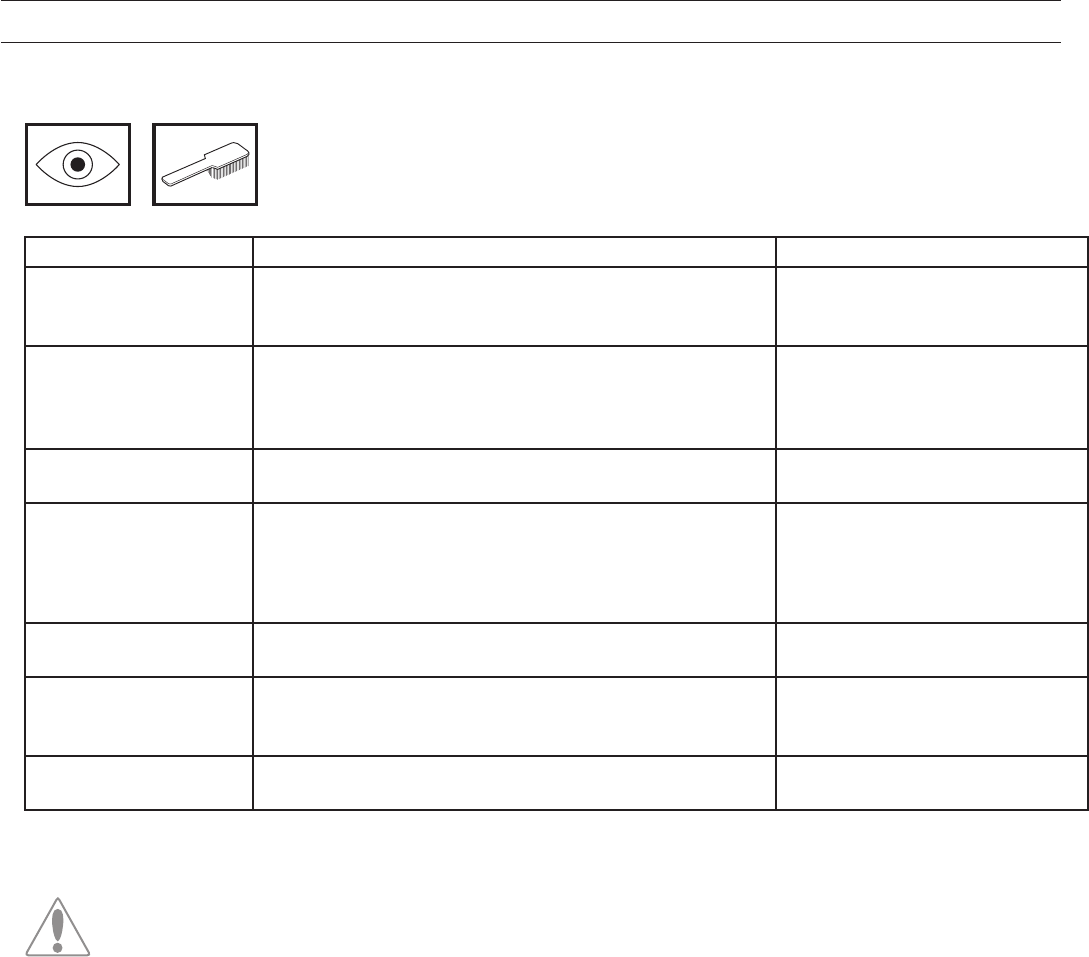

Maintenance schedule

Item Action Frequency

Check that head locks

are tight.

Tighten head locks and re-set in thread-locking com-

pound if required (Suggested thread-locking compound

Loctite 680)

Daily

Inspect heads for slop/

broken “fi ngers” if using

spring steel heads.

Examine machine heads while machine tipped back.

Disconnect Planetary Drive motor (small motor) and run

discs at lowest speed. Check to see how concentric/true

grinding heads are running.

Daily

Check effectiveness of

planetary seal.

Remove planetary head motor/gearbox system and

check for presence of dust under machine cover .

Weekly

Check condition of

chain ring.

Remove planetary head motor/gearbox system and in-

spect chain links in chain ring. Ensure links are clean and

free from build-up.

Weekly with Planetary Seal

Check condition of

Drive Sprocket.

Remove planetary head motor/gearbox system and

inspect condition of planetary drive sprocket.

Weekly with Planetary Seal

Inspect internal compo-

nents of machine.

Remove belt tensioner cover plate and check inside

machine for dust, moisture or belt fragments. Ensure to

re-seal cover plate with silicone sealant.

6 monthly

Clean contents of elec-

trical cabinet.

Blow out inside of electrical cabinet and variable speed

drives or frequency converters with DRY compressed air.

Every 2 months

IMOPRTANT!

Prior to removing belt tensioner cover plate,

ensure cover plate and area surrounding cover

plate are totally clean. Avoid debris from enter-

ing into inside of machine.

Maintenance schedule