32

4.6 COOLANT (Continued)

After the unit is drained and a new coolant filter element

is installed, refill the system with fresh coolant. Bring the

receiver level of coolant up to the midpoint of the sight

glass. Replace the fill cap. Start the compressor and run

it for a short time. The correct coolant level is at the

midpoint of the sight glass with the unit running in the

‘UNLOADED” mode.

4.7 SEPARATOR TANK

SCAVENGE SCREEN/ORIFICE

TOOLS REQUIRED

■ Open end wrench

■ Pliers

PROCEDURE

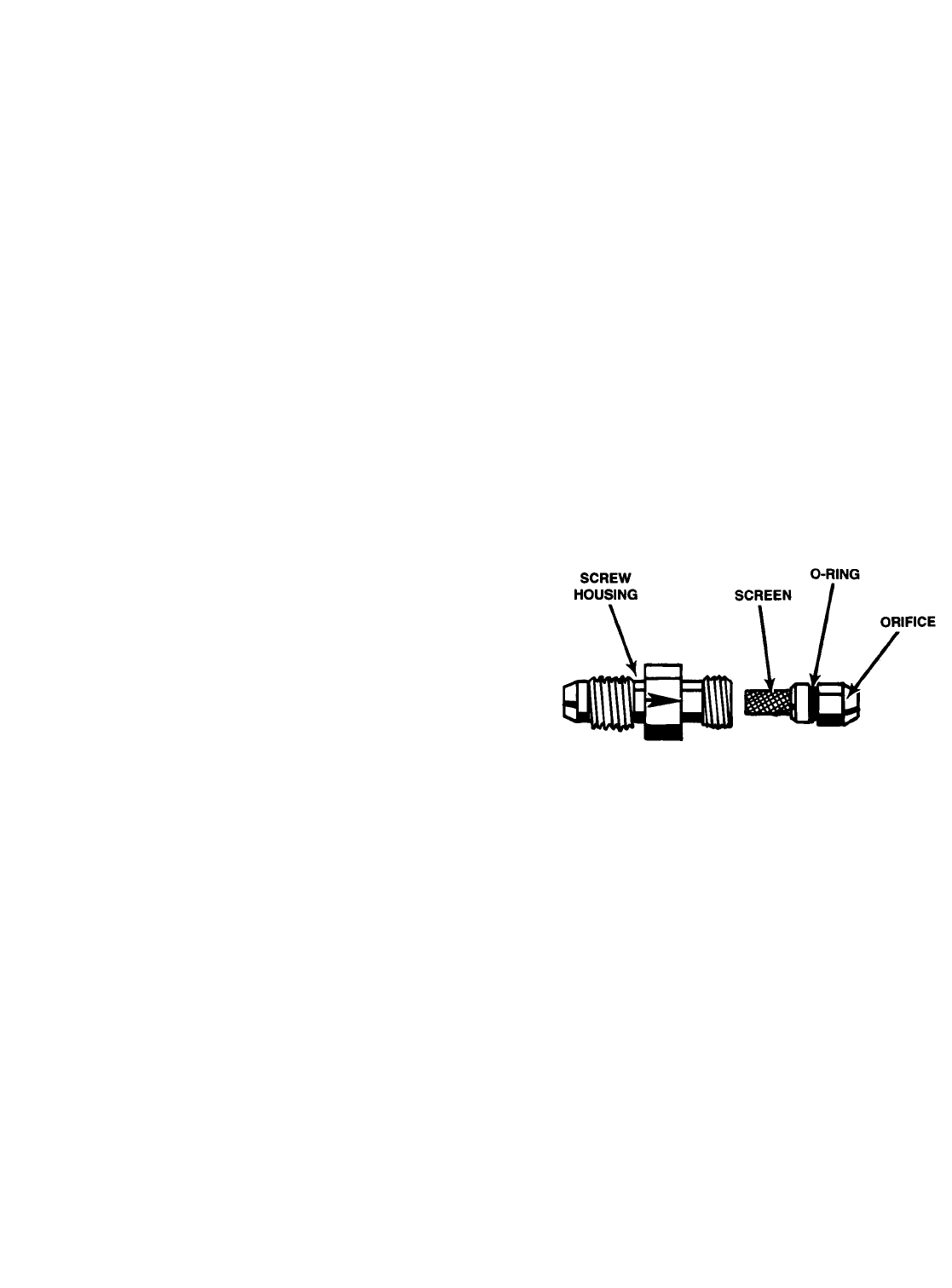

The screen/orifice assemblies are similar in appearance

to a straight tubing connector and will be located

between two pieces of 1/4 inch O.D. scavenge line

tubing.

The main body is made from 1/2 inch hexagon shaped

steel and the diameter of the orifice and a direction-of-

flow arrow is stamped in flat areas of the hexagon.

A removable screen and orifice is located in the exit end

of the assembly (See Figure 4.7-1) and will require

cleaning as outlined in the Maintenance Schedule,

Section 4.1.

To remove the screen/orifice, disconnect the scavenge

line tubing from each end. Hold the center section firmly

and use a pair of pliers to gently grasp the exit end of the

assembly that seals against the scavenge line tubing.

Pull the end out of the center section while using care to

prevent damage to the screen or sealing surfaces.

Clean and inspect all parts prior to reinstallation.

When the assembly is installed, confirm the direction of

flow to be correct. Observe the small arrow stamped in

the center section and ensure the direction flow to be

from the separator tank to the airend.

FIGURE 4.7-1 SEPARATOR TANK SCAVENGE

SCREEN/ORIFICE