04584595_ed3 5

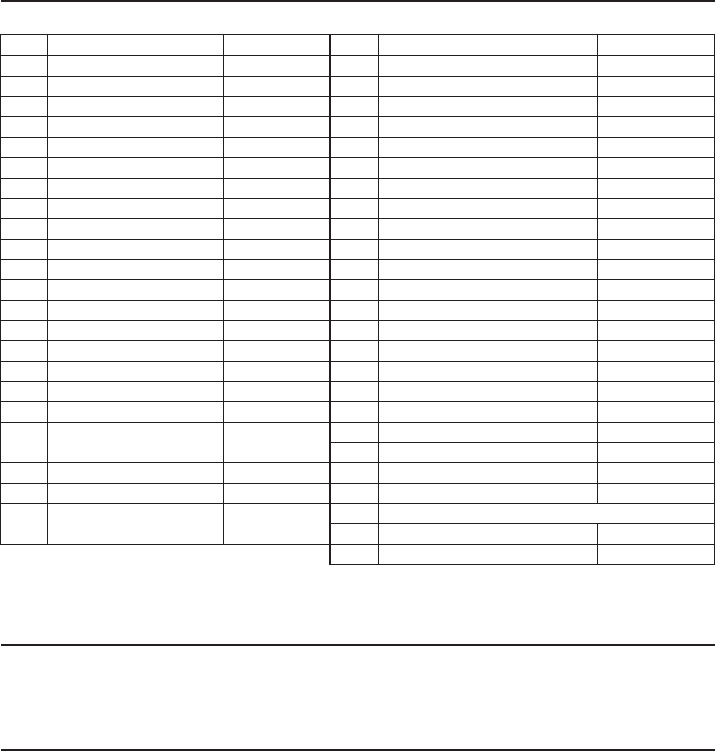

2902P and 2902SB Air Impactool Power Unit - Parts List

Item Part Description Part Number Item Part Description Part Number

† 49 Rear Rotor Bearing Retainer MF-18 • 70 Socket Retaining Ring 1702-425

† 50 Rear Rotor Bearing 401-22 • 71 Retainer Support Ring 1702-426

51 Rear End Plate 201-12 Quick-Change Anvil Assembly (1/4” hex) 1702-A926-4

52 Rotor 401-53 72 Quick-Change Anvil 1702-926-4

† • 53 Vane Packet (Set of 6 Vanes) 401-42A-6 73 Thrust Ring Lock 5C1-853

54 Cylinder 401-3 74 Thrust Ring I0A902A2-932-4

55 Cylinder Dowel HH92-74 • 75 Retaining Sleeve Spring 2U-931-4

56 Front End Plate 201-11 76 Retaining Ball (5/32” diameter steel ball) 2U-696

† 57 Front Rotor Bearing R00H-97 77 Retaining Sleeve 2U-930-4

58 Hammer Frame Washer 1702-706 • 78 Retaining Sleeve Stop 2U-933-4

59 Hammer 1702-724A Quick-Change Anvil Assembly (7/16” hex) 1702-A926-7

60 Hammer Frame Assembly 1702-A703A 79 Quick-Change Anvil 1702-926-7

61 Hammer Pins (2) 1702-704 80 Quick-Change Anvil Body I0A902A5-925

62 Hammer Case Assembly 2902-A727 81 Body Lock Pin I0A902A5-936

63 Hammer Case Bushing 401-641 • 82 Thrust Ring Lock 4U-933-7

* Warning Label WARNING-2-99 83 Thrust Ring 4U-932-7

† 64 Hammer Case Gasket 2902-36 84 Retaining Sleeve Spring 4U-931-7

65 Hammer Case Cap Screw (3) 1702-638 85 Retaining Ball (7/32” diameter steel ball) 2U-722

66

3/8” Square Drive Anvil Assembly

1702-P726

86 Retaining Sleeve I0A902A5-930

(with Pin-Type Retainer) * Horizontal Hanger 1901-366

† • 67 Socket Retaining Plunger 5020-716 * Vertical Hanger 1901-365

† • 68 Retaining Plunger Spring 401-718 * Socket Adapter (3/8” to 1/2”) 2U-215

69

3/8” Square Drive Anvil Assembly

1702-A626

* Quick-Change Chuck

(with Ring-Type Retainer) for 1/4” hex shank accessories 2U-A925-4

for 7/16” hex shank accessories 502-A925-7

* Not Illustrated.

† Indicates Tune-up Kit part.

• To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock one (pair or set) of each

part indicated by a bullet (•) for every four tools in service.

Parts and Maintenance

When the life of the tool has expired, it is recommended that the tool be disassembled, degreased and parts be separated by material so

that they can be recycled.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest Ingersoll Rand Oce or Distributor.

Related Documentation

For additional information refer to:

Product Safety Information Manual 04580916.

Product Information Manual 04584769.

Maintenance Information Manual 04584231.

Manuals can be downloaded from www.ingersollrandproducts.com.