PAGE2OF4

650556Ć1

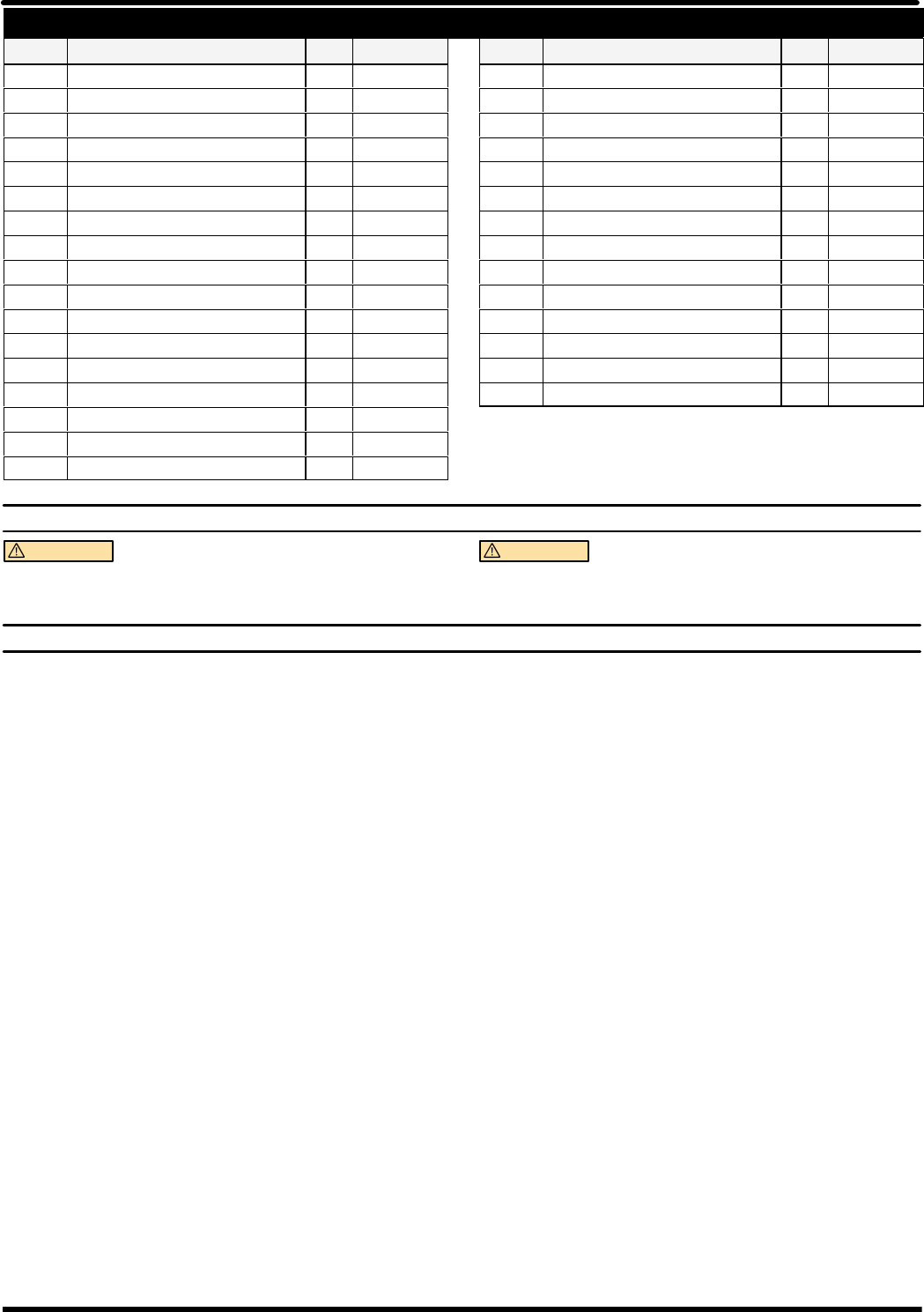

PARTS LIST / 650556-1

ITEM DESCRIPTION(Size in Inches)

QTY

PART NO. ITEM DESCRIPTION(Size In Inches)

QTY

PART NO.

1 TwoBall PistonPump (1) 650685ĆP43

2 CartAssembly (IncludesItems 3thru14) (1) 67139

3 Cotter Pin (3/32") (2) Y15Ć35ĆC

4 Washer (4) 91522

5 Tip (2) 91011

6 Washer(3/8") (6) Y13Ć6ĆC

7 Screw(3/8"Ć 16x1Ć1/4") (4) Y6Ć66ĆC

8 Nut(3/8" Ć16) (4) Y12Ć6ĆC

9 WheelAssembly (2) 91515

10 Brace (1) 95102

11 Screw(5/16"Ć 18x3/4") (4) Y6Ć53ĆC

12 Nut(5/16" Ć18) (4) Y12Ć5ĆC

13 Washer(5/16") (4) Y14Ć516ĆC

14 Cart Welding Assembly (1) 67138

15 MaterialFilter (IncludesItem 16) (1) 651422Ć70

16 Plug(3/8") (1) Y17Ć13ĆS

17 Muffler (1) 91790ĆZZ

j 18 3/4" SuctionHoseAssembly (1) 622606Ć5

j 19 90_ Elbow(3/4") (1) Y43Ć15ĆS

j 20 Suction Tube (5Gallon) (1) 94263Ć1

21 HoseAssembly (1) 628092ĆF

22 Gauge (1) 100067

23 ModularPiggybackFilter/Regulator (1) P29241Ć100

24 Nipple(1/2"x 1Ć1/2"(m)) (1) Y27Ć54ĆC

25 Bushing(1/2" Ć14(m) x1/4"Ć 18(f)) (1) 94271

26 Nipple(1/4"Ć 18(m)) (2) 1950

27 StreetTee(1/4"Ć 18) (1) 94270

28 NeedleValve (1) 94269

29 Adapter(1" (m)x1/2" (f)) (1) 94256

30 90_ Adapter(1"(m) x1/4"(f) x3/4"(f)) (1) 94254

31 Plug (1) Y17Ć11ĆS

jParts included in 67140Ć1 Asm (std)

Available: 67140Ć2 Asm. uses 94263Ć2 (36" Inlet Tube)

OPERATING INSTRUCTIONS

WARNING

DO NOT EXCEEDMAXIMUM OPERATING PRESĆ

SURE OF 6000 P.S.I. (414 BAR) AT 100 P.S.I. (6.9 BAR) AIR INĆ

LET PRESSURE.

WARNING

REFER TO THE PUMP MANUAL FORADDITIONĆ

AL OPERATING AND SAFETY PRECAUTIONS AND OTHER

IMPORTANT INFORMATION.

INSTALLATION

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

This unit comesassembled exceptforthe airsupply hose,gunand maĆ

terial hose which must be attached.

• A connector, coupler and air supply hose and must be supplied

to the air regulator.

• Attach a Ground wire to a suitable ground and the Ground Lug

provided on the pump Air Motor.

• Keep containers covered to prevent contamination.

1. Turn the knob on the air regulator counterĆclockwise to zero p.s.i.

2. Attach hose and gun. Place pump inlet tube into a full container of

material.

3. Start the pump to cycle by turning the airregulator knob clockwise.

The pump will cycle several strokes until pressure is built up in the

system, atwhich timeitwill stall,checkfor anyloosefittings orleakĆ

age. Check all connections and reĆtighten as necessary.

4. Relief Valve (28) is used to relieve pressure in the hose in order to

change spray tips. Open the relief valve to relieve pressure. Close

the relief valve to continue spray operation.