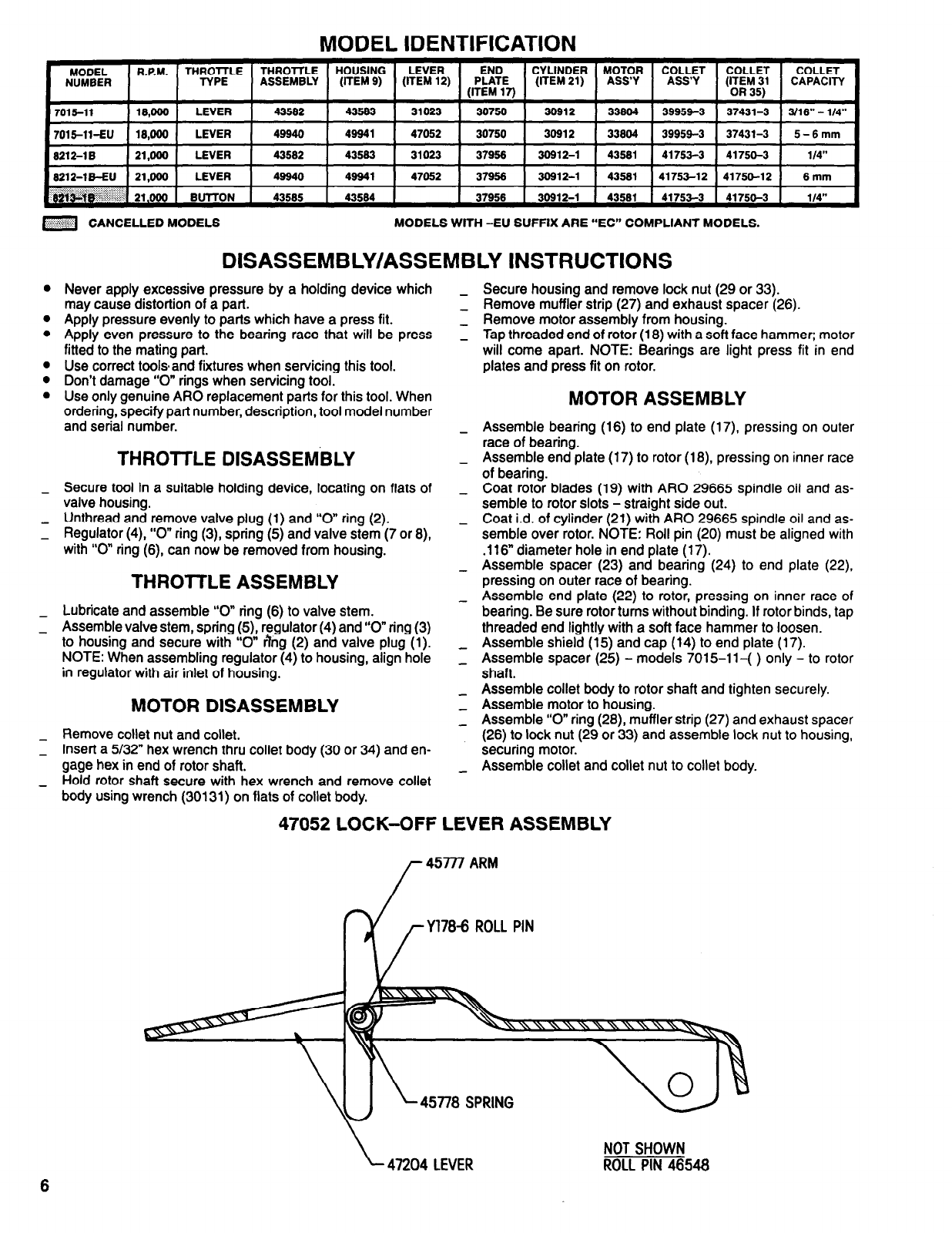

MODEL IDENTIFICATION

MODEL

NUMBER

7015-11

RPM

LEVER END CYLINDER MOTOR COLLET COLLET COLLET

THROTTLE THROTTLE HOUSING

ASSEMBLY

(ITEM 9)

(ITEM 12) PLATE

ASS’Y

ASS’Y

(ITEM 31

CAPACITY

(ITEM 17)

(ITEM 21)

or 35

18,000

LEVER 43582

43583 31023 30750 30612

33804 39954-3 37431-3 3/16” - 1/4”

7015-11-EU 18,000 LEVER 49940 46941 47052 30750 30912 33804 39959-3 37431-3 5-6mm

8212-1B 21,000 LEVER 43602 43583 31023 37968 30612-1 43581 41753-3 41750-3 1/4”

8212-1B-EU 21,000 LEVER 49640 49641 47052 37956 30612-1 43581 41753-12 41750-12 6mm

8213-1B 21,000 BUTTON 43685 43584 37956 30912-1 43581 41753-3 41750-3 1/4”

CANCELLED MODELS

MODELS WITH -EU SUFFIX ARE “EC” COMPLIANT MODELS.

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

l

l

0

l

l

0

-

-

-

-

Never apply excessive pressure by a holding device which

may cause distortion of a part.

Apply pressure evenly to parts which have a press fit.

Apply even pressure to the bearing race that will be press

fitted to the mating part.

Use correct tools and fixtures when servicing this tool.

Don’t damage “0” rings when servicing tool.

Use only genuine ARO replacement parts for this tool. When

ordering, specify part number, description, tool model number

and serial number.

THROTTLE DlSASSEMBLY

Secure tool in a suitable holding device, locating on flats of

valve housing.

Unthread and remove valve plug (1) and “0” ring (2).

Regulator (4), “0” ring (3), spring (5) and valve stem (7 or 8),

with “0” ring (6), can now be removed from housing.

THROTTLE ASSEMBLY

Lubricate and assemble “0” ring (6) to valve stem.

Assemble valve stem, spring (5) regulator (4) and “0” ring (3)

to housing and secure with “0” ring (2) and valve plug (1).

NOTE: When assembling regulator (4) to housing, align hole

in regulator with air inlet of housing.

MOTOR DISASSEMBLY

Remove collet nut and Collet.

Insert a 5/32” hex wrench thru collet body (30 or 34) and en-

gage hex in end of rotor shaft.

Hold rotor shaft secure with hex wrench and remove collet

body using wrench (30131) on flats of collet body.

Secure housing and remove lock nut (29 or 33).

Remove muffler strip (27) and exhaust spacer (26).

Remove motor assembly from housing.

Tap threaded end of rotor (18) with a soft face hammer; motor

will come apart. NOTE: Bearings are light press fit in end

plates and press fit on rotor.

MOTOR ASSEMBLY

Assemble bearing (16) to end plate (17) pressing on outer

race of bearing.

Assemble end plate (17) to rotor (18) pressing on inner race

of bearing.

Coat rotor blades (19) with ARO 29665 spindle oil and as-

semble to rotor slots - straight side out.

Coat i.d. of cylinder (21) with ARO 29665 spindle oil and as-

semble over rotor. NOTE: Roll pin (20) must be aligned with

.116” diameter hole in end plate (17).

Assemble spacer (23) and bearing (24) to end plate (22).

pressing on outer race of bearing.

Assemble end plate (22) to rotor, pressing on inner race of

bearing. Be sure rotor turns without binding. If rotor binds, tap

threaded end lightly with a soft face hammer to loosen.

Assemble shield (15) and cap (14) to end plate (17).

Assemble spacer (25) - models 7015-11-( ) only - to rotor

shaft.

Assemble collet body to rotor shaft and tighten securely.

Assemble motor to housing.

Assemble “0” ring (28) muffler strip (27) and exhaust spacer

(26) to lock nut (29 or 33) and assemble lock nut to housing,

securing motor.

Assemble collet and collet nut to collet body.

47052 LOCK-OFF LEVER ASSEMBLY

Y178-6 ROLL PIN

45778 SPRING

47204 LEVER

NOT SHOWN

ROLL PIN 48548