TROUBLE SHOOTING

LISTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE GRINDER TO MALFUNCTION. MALFUNCTIONS BEYOND THE SCOPE OF THIS MANUAL

SHOULD BE BROUGHT TO THE ATTENTlON OF YOUR ARO REPRESENTATIVE OR RETURN THE TOOL TO THE FACTORY FOR REPAIR.

CONDITION

LOW SPEED AND

POWER OR GRIND-

ER WILL NOT RUN.

THROTTLE VALVE

1. DAMAGED VALVE PIN OR COM-

HARD TO OPERATE. PONENTS.

TOOL WILL NOT

SHUT OFF.

1. DAMAGED VALVE COMPONENTS.

POSSIBLE CAUSE

1. INADEQUATE AIR SUPPLY.

2. AIR REGULATOR (30603) IMPROPER-

LY ADJUSTED.

3. AIR INLET OR EXHAUST SCREEN

PLUGGED.

4. OBSTRUCTION IN THROTTLE VALVE

OR VALVE NOT OPENING.

5. MOTOR NOT BEING PROPERLY LU-

BRICATED.

6. ROTOR BLADE IS MISSING, INCOR-

RECTLY INSTALLED, BADLY WORN

OR BEARING FAILURE.

CORRECTIVE ACTION

1.

CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUST-

MENT (90 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

2.

CHECK REGULATOR ADJUSTMENT TO BE SURE OF MAXIMUM

AIR FLOW.

3. INSPECT, WASH CLEAN.

4.

DISASSEMBLE THROTTLE, CLEAN, INSPECT FOR OBSTRUC-

TIONS OR DAMAGED PARTS.

5.

APPLY 2 OR 4 DROPS OF SPINDLE OIL IN AIR INLET. RUN TOOL

TO ALLOW OIL TO ENTER MOTOR - BE CERTAIN OILER IS

FULL OF OIL.

6.

DISASSEMBLE MOTOR, CLEAN AND INSPECT FOR PROPER

INSTALLATION, REPLACE BLADES AND/OR BEARINGS IF NEC-

ESSARY.

1.

DISASSEMBLE VALVE COMPONENTS, INSPECT, REPLACE IF

NECESSARY.

1.

DISASSEMBLE VALVE COMPONENTS, INSPECT, REPLACE

PARTS IF NECESSARY.

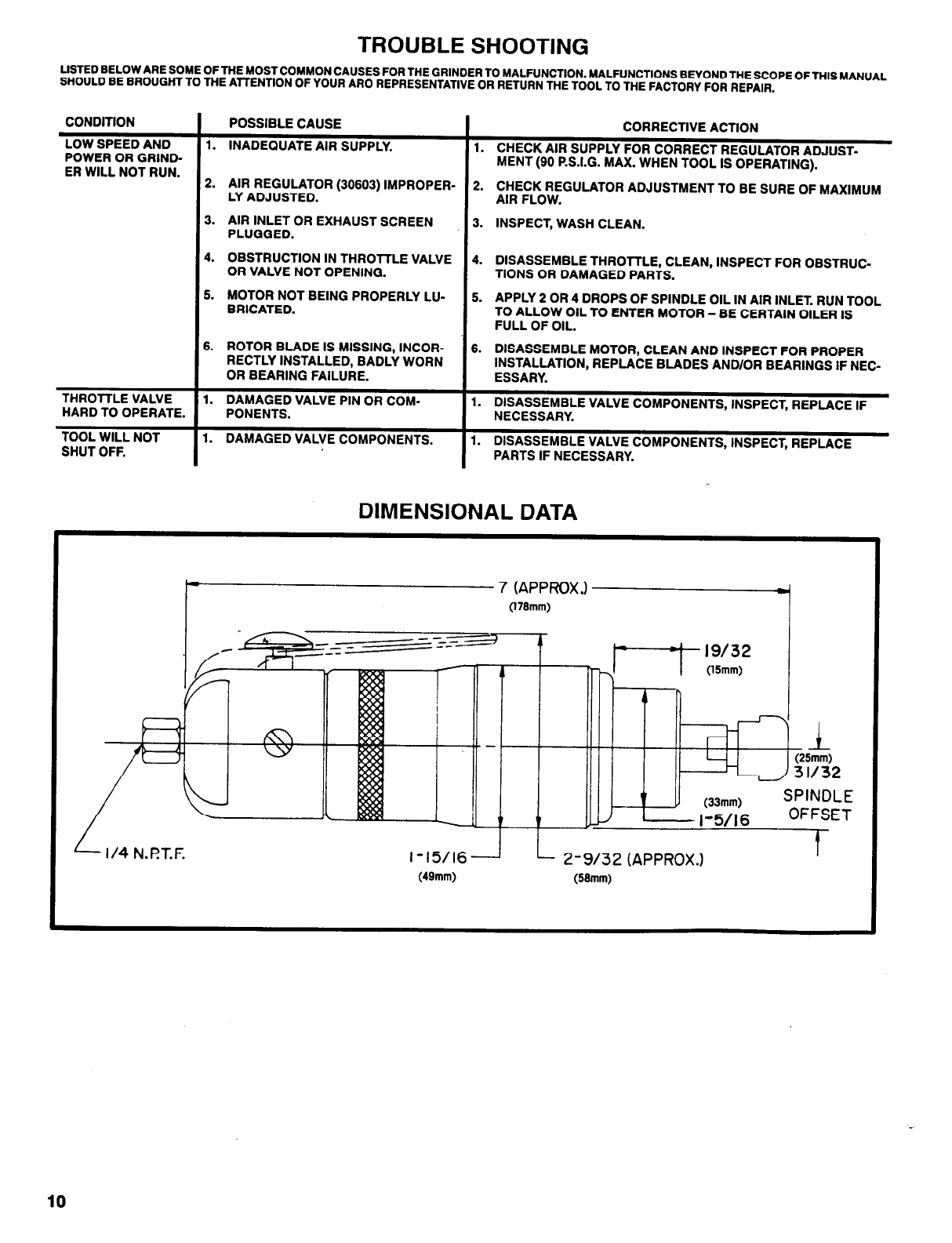

DIMENSIONAL DATA

(49mm)

2-9/32 (APPROX.)

(56mm)

10