6

12a342b

6

5

78

14151617

9

10

11

12

13

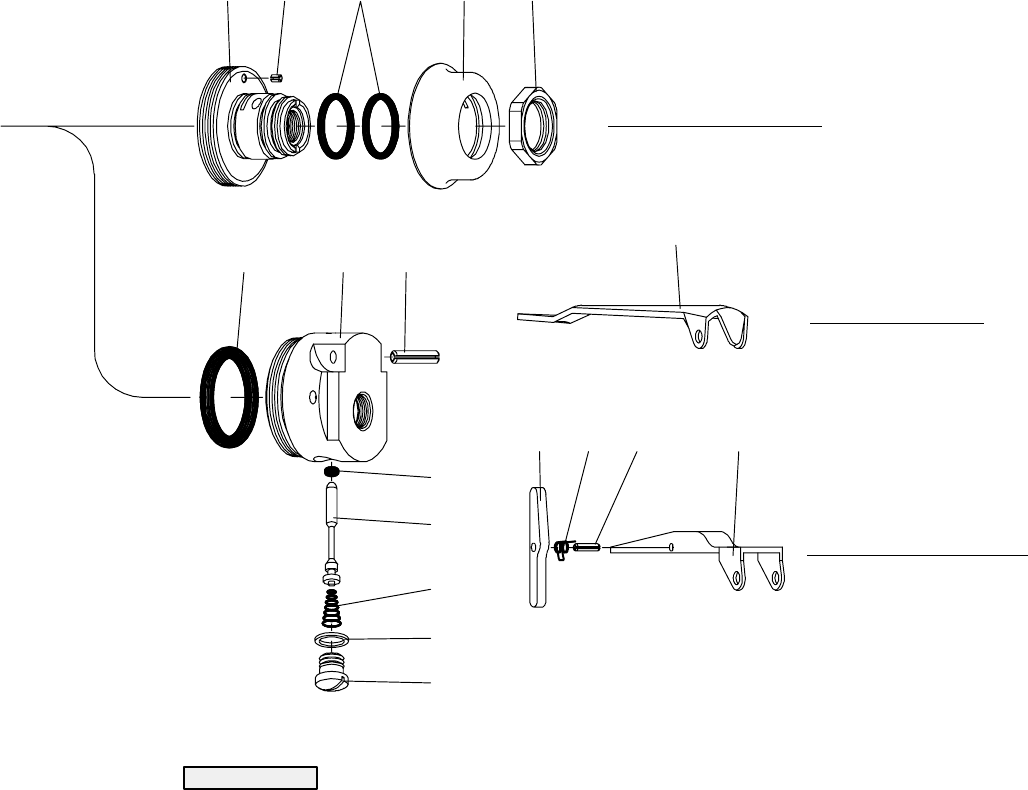

MODEL 7980–A–( )

MODEL 7980–2

MODEL 7980–2–EU

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

NOTICE

• Never apply excessive pressure by a holding device which

may cause distortion of a part.

• Apply pressure evenly to parts which have a press fit.

• Apply even pressure to the bearing race that will be press

fitted to the mating part.

• Use correct tools and fixtures when servicing this tool.

• Don’t damage ‘‘O” rings when servicing this tool.

• Use only genuine ARO replacement parts for this tool. When

ordering, specify part number, description, tool model number

and serial number.

DISASSEMBLY

_ Remove hose assembly (not shown) from the inlet of the tool.

_ Insert A 1/8” diameter pin thru the hole in the housing (26), lock

sleeve (29) and spindle (28).

_ Using a wrench on flats of housing cap (32), unthread and re-

move housing cap (32) and lock sleeve (29).

_ Using a wrench on flats of nosepiece (34), unthread and re-

move from spindle, releasing collet (33).

• Models 7980–2–( ) – Place head (7) in a vise and, using a

strap type wrench, unthread and remove housing (26).

• Models 7980–A–( ) – Clamp wrench (30131) flatwise in a vise

and place slot in air inlet of tool on wrench. Using a strap type

wrench, unthread and remove housing (26).

_ Remove nozzle plate (18).

_ Insert a 1/8” diameter pin thru the hole in housing (26) and

spindle (28), and remove nut (19).

_ Press spindle (28) out nose end of housing.

_ Remove impellers (21, 22 and 24), sleeve (20), bearing (23)

and spacer (25) from housing.

_ Do not remove bearing (27) from spindle unless damage is ev-

ident. To remove, press off of spindle.

• Models 7980–2–( ) – Remove valve screw (13) and seal (12),

releasing spring (11), stem valve (10) and ‘‘O” ring (9).

• Models 7980–A–( ) – To remove ‘‘O” rings (3), remove nut (1),

releasing throttle and bushing assembly (2a).

ASSEMBLY

_ Assemble bearing (27) to spindle (28), pressing on inner race

of bearing.

_ Assemble spindle into housing theu nose end, pressing on

outer race of bearing.

_ Assemble spacer (25), impeller (24), impeller (22) with bear-

ing (23) and impeller (21) with sleeve (20) to spindle, securing

with nut (19). NOTE: Assemble impellers with grooves in the

direction shown on page 4.

_ Assemble nozzle plate (18) and head to tool.

_ Assemble lock sleeve (29) to housing, aligning hole in lock

sleeve (29) with hole in housing.

_ Insert a 1/8” diameter pin thru hole in housing and lock sleeve

(29).

_ Assemble housing cap (32) to housing, tightening securely.

_ Assemble collet (33) and nosepiece (34) to spindle.

• Models 7980–2–( ) – Grease and assemble ‘‘O” ring (9) to

stem valve (10). Assemble stem valve (10) and spring (11) to

head, securing with seal (12) and valve screw (13).