connected to the same circuit, the total electrica! load must be

considered in selecting the proper wire size DO NOT USE

UNDERSIZE WIRE

FUSES., Refer to the National Electric Code to determine the proper

fuse or circuit breaker rating required. When selecting fuses,

remember the momentary starting current of an electric motor is

greater than its full load current Time-delay or "slow-blow" fuses

are recommended.

Single-Phase Wiring

uJ L=J

L1

T = Supply Line Terminal

L = Load Terminal

used disconnecLorclrcu_tbreaker

Pressure switch

(inctltde_ on/auto-off switch)

Singie phase

m_or

COMPRESSOR LUBRICATION

CAUTION Do not operate without lubricant or with inadequate

lubricant. Ingersoll-Rand fs not responsible for

compressor failure caused by inadequate

lubrication

SYNTHETIC LUBRICANT. We recommend thgersolI-Rand

synthetic compressor lubricant from start-up See the WARRANTY

section for extended warranty information

ALTERNATE LUBRfOANTS. You may use a petroleum-based

lubricant that is premium quality, does not contain detergents,

contains only anti-rust, anti-oxidation, and anti-foam agents as

additives, has a fieshpoint of 440°F (227°C) or higher, and has an

auto-ignition polnt of 650=F (343°C) or higher

See the petroleum lubricant viscosity table below The table is

intended as a general guide only Heavy duty operating conditions

require heavier viscosities,, Refer specific operating conditions to

_our dealer for recommendations

Temperature Around Unit Vlscosib' @ 100"F (37 8"C) Viscosity Grade

_F "C SUS Centtstokes 1SO SAE

40 & below 4 4 & below 150 32 32 10

40 - BO 4 4 - 26 7 500 t10 !00 30

80 - 125 26.7 - 51.0 750 165 '_50 40

you use a petroleum-based compressor lubricant at start-up and

decide to convert to Ingersoll-Rand synthetic compressor lubricant

later on, the compressor valves must be thoroughly decarbonized

and the crankcase must be flushed before conversion

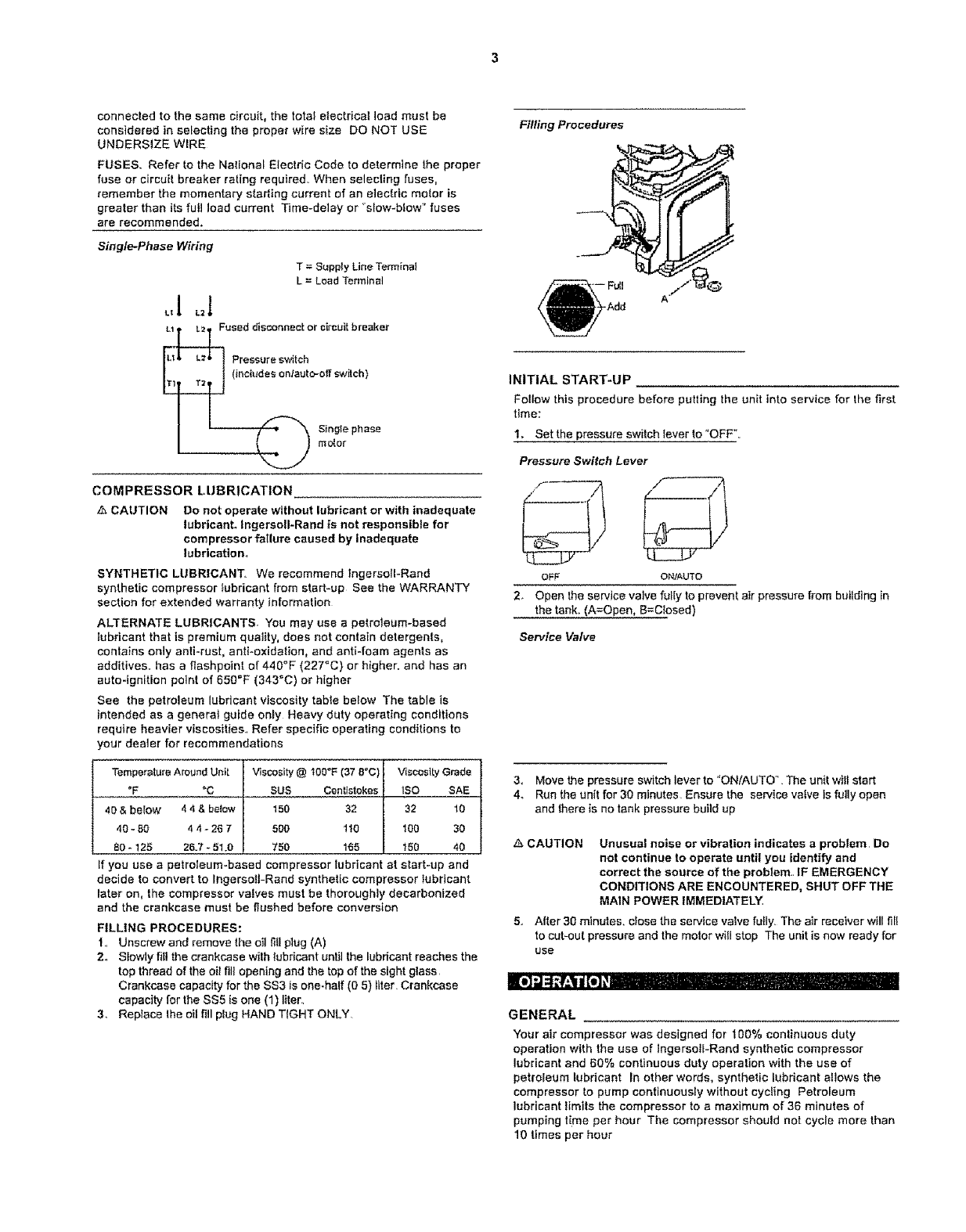

FILLING PROCEDURES:

t,, Unscrew and remove the ell fillplug (A)

2. Slowly flit the crankcase with lubricant until the lubricant reaches the

top thread of the sit filI opening and the top of the sight glass

Crankcase capacity for the SS3 Is one-half (0 5) Iiter Crankcase

capacity for the SS5 is one (1) liter.,

3. Replace the oil fill plug HAND TIGHT ONLY

Filling Procedures

INITIAL START-UP

Follow this procedure before putting the unit into service for the first

time:

t. Set the pressure swffch lever to "OFF"..

Pressure Switch Lever

OFF" ON/AUTO

2. Open the service valve fully to prevent air pressure from building in

the tank. (A=Open, B=Closed)

Service Valve

3. Move the pressure switch lever to "ON/AUTO _ The unit will start

4. Run the unit for 30 minutes Ensure the service vaive is fully open

and there is no tank pressure build up

CAUTION

Unusual noise or vibration indicates a problem Do

not continue to operate until you identify and

correct the source of the problem., IF EMERGENCY

CONDITIONS ARE ENCOUNTERED, SHUT OFF THE

MAIN POWER IMMEDIATELY,

5., After 30 minutes, close the service valve fully. The air receiver will fill

to cut-out pressure and the motor will stop The unit is now ready for

use

B[o]"J=1:_.,_II[=]h

GENERAL

Your air compressor was designed for f 00% continuous duty

operation with the use of Ingersoll-Rand synthetic compressor

lubricant and 60% continuous duty operation with the use of

petroleum lubricant In other words, synthetic lubricant allows the

compressor to pump continuously without cycling Petroleum

lubricant limits the compressor to a maximum of 36 minutes of

pumping time per hour The compressor should not cycle more than

10 times per hour