20

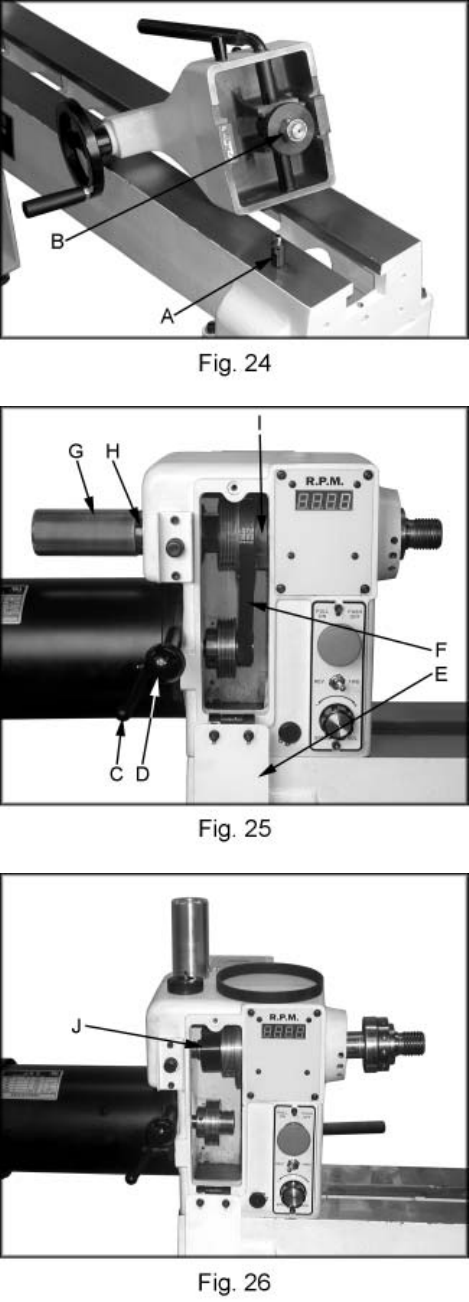

Adjusting Clamping Mechanism

The clamps are pre-set at the factory and should

not need any adjustment. However, if

adjustment is needed remove the stud (A, Fig.

24). Loosen the locking handle and slide the

headstock, tailstock or tool rest to the edge of

the bed and slightly turn the hex nut (B, Fig. 24).

Slide back into position and test the handle to

make sure it securely locks.

Changing the Belt and Bearings

Changing belt and bearings can be a difficult

task, and should be performed by a JET

authorized repair station. Remove headstock

and take into a repair station for servicing.

1. Disconnect the machine from the power

source!

2. Loosen the locking handle (C, Fig. 25), and

lift up on the tensioning handle (D, Fig. 25)

to remove tension from the poly v-belt.

3. Open door (E, Fig. 25), and remove the belt

(F, Fig. 25) from the lower pulley.

4. Loosen two set screws in the handwheel (G,

Fig. 25) and remove.

5. Loosen socket head cap screw enough to

unthread the clamping nut (H, Fig. 25).

6. Loosen two set screws in the right hand

pulley (I, Fig. 25).

7. Loosen set screw in the collar (J, Fig. 26)

8. Use a wood dowel, or aluminum stock to

knock spindle towards the tailstock. Use a

material that is softer than the spindle so

you do not mushroom end of spindle. Go

only far enough to remove belt from spindle,

see Figure 26.

9. Now you can replace the belt or bearings.

There are two bearings #5, and 10 that can

be seen in “Headstock Assembly,” page 24.

10. To reassemble reverse the procedure.

Note: When reinstalling clamping nut

thread it on to the spindle until its snug.

Then back off slightly and tighten the socket

head cap screw.