15

5. Rotate the speed dial to the desired setting.

(The dial can also be rotated while the blade

is running.) Refer to the chart in Figure 17

for recommended blade speed and

downfeed rate settings.

6. Press the blade run button on the hand grip

to start the saw blade.

7. Use the hand grip to slowly bring down the

bow until the blade makes light contact with

the workpiece. Now begin to apply gradual

pressure on the workpiece and complete the

cut.

8. Release the blade run button on the hand

grip and push the bow back up toward

vertical.

9. If finished with the operation, push the

STOP button.

Blade Speed and Downfeed Pressure

The Band Saw offers continual variable speed

within the specified range; the speed of the

blade is set using the speed control dial next to

the switch.

A general rule is the harder the material being

cut, the slower the blade speed.

Also important is the downfeed pressure, which

is the amount of pressure directed by the blade

against the workpiece; this is controlled

manually by the operator using the grip handle.

Downfeed pressure can be deduced by

“Recommended Cutting Times” in Figure 17.

Following are general recommendations for

speed control dial positions as they relate to the

various speeds and applications:

• 30 m/min. (dial position 1) for stainless steel,

alloy steel and bearing bronzes.

• 45-50 m/min. (dial position 2-3) for mild

steel, hard brass or bronze.

• 60-80 m/min. (dial position 4-6) for soft

brass, aluminum or other light materials.

Material chips or shavings are the best indicator

of proper blade speed and downfeed pressure.

The ideal chip is thin, tightly curled and warm to

the touch. Chips that range from golden brown

to black indicate excessive force. Blue chips

indicate extreme heat from too high a blade

speed, which will shorten blade life. Thin or

powdered chips indicate insufficient downfeed

rate.

Maintenance

Disconnect the band saw’s

plug from the power source before doing any

maintenance.

Clean the band saw regularly after each day’s

work. Clear metal shavings with a suction device

or brush, not your hands. Do not use

compressed air.

If the power cord is worn, cut, or damaged in

any way, have it replaced immediately.

All of the ball bearings are packed with grease at

the factory. They require no further lubrication.

Lubricate the vise lead screw with a general-

purpose grease.

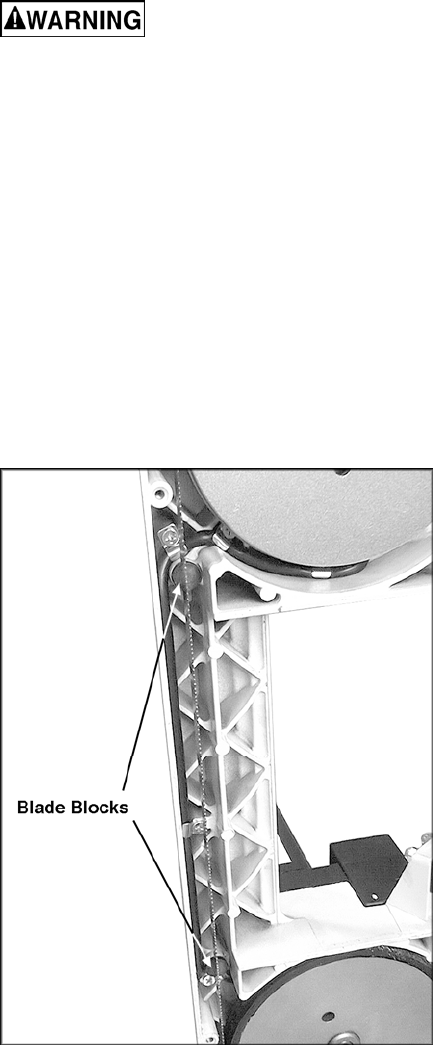

Inspect the blade blocks (Figure 18). If they are

worn, they should be replaced. Remove the

blade and replace the blocks.

Figure 18

If the band saw will be unused for a period of

time, slacken the blade tension before storage.

This will help prolong the life of the blade.