Maintenance

28 Operator’s Manual

MAINTENANCE

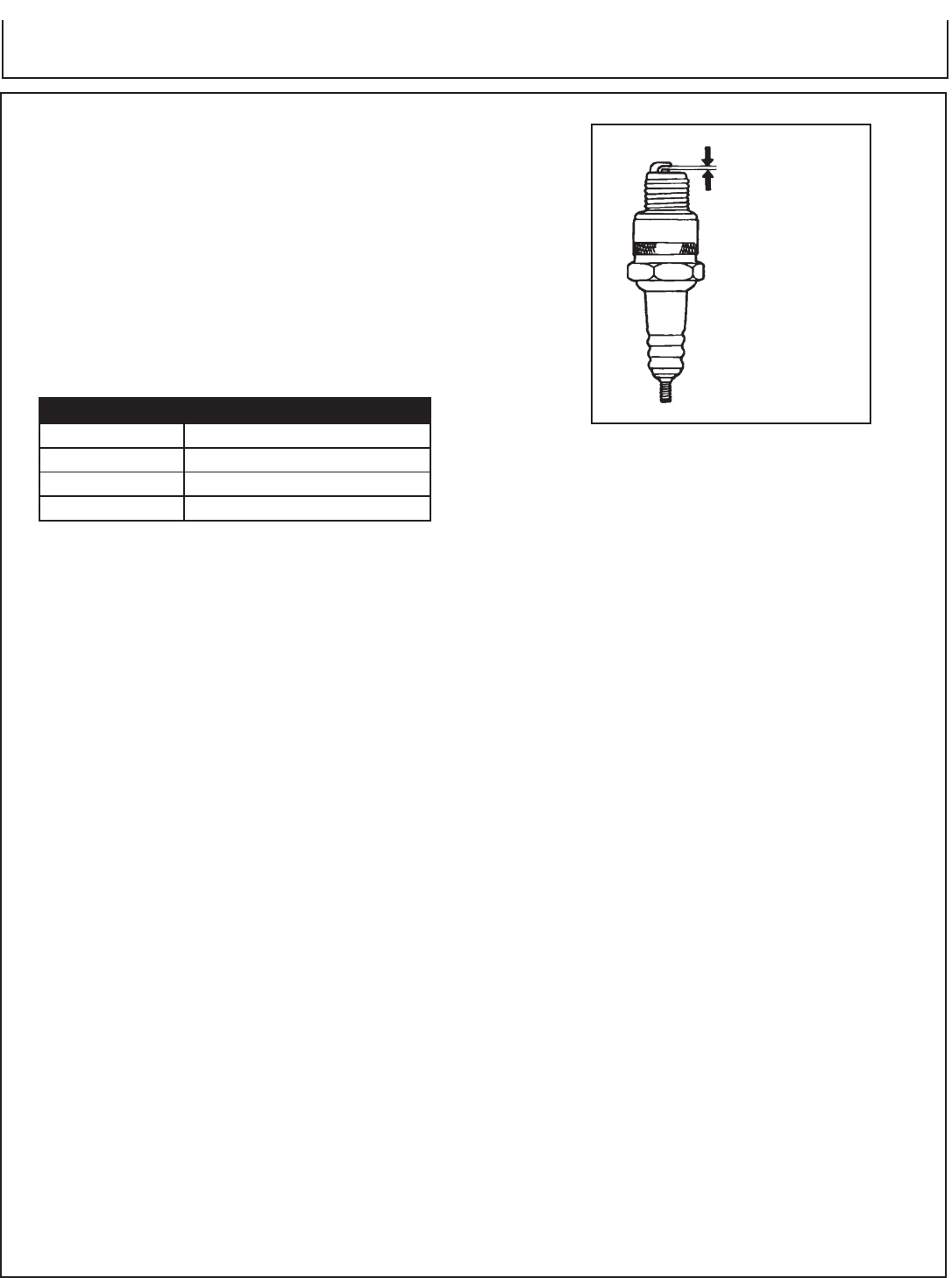

CLEANING AND GAPPING SPARK PLUG:

If the plug is contaminated with carbon, remove it using a

plug cleaner or wire brush.

Check the spark plug gap and reset it if necessary. The spark

plug gaps are listed below. To change the gap, bend the side-

electrode only, using a spark plug tool. (Fig. 3)

Install and tighten the spark plug. Connect the spark plug

lead.

Recommended Spark Plug:

BELT TENSION ADJUSTMENT:

To maintain peak performance of your unit, it may be

necessary to adjust the belt tension on occasion. Follow the

procedure outlined below:

1. Remove the beltguard and loosen the two nuts on each

side of the pump or engine. There are a total of 4 nuts.

2. Turn the cap screw clockwise until a 1/2 inch belt

deection is noticed between the pulleys.

3. Tighten the side nuts.

4. Put a straight edge across both pulleys. If necessary,

loosen one set of pulley screws and adjust in or out to

properly align. Tighten the pulley screws and check the

tension again.

5. Replace the beltguard and tighten the fasteners

securely.

Spark Plug Gap

(See recommendations)

Engine Honda

Spark Plug NGK BPR6ES

Spark Plug Gap 0.7 - 0.8 mm (0.03 in.)

Torque - New 8.7-10.9 ft-lb

Torque - Retighten 16.6-19.5 ft-lb

(Fig. 3)