26 Operator’s Manual

Service

MAINTENANCE

AIR CLEANER:

WARNING: RISK OF FIRE OR EXPLOSION. DO

NOT USE GASOLINE OR LOW FLASH-

POINT SOLVENTS TO CLEAN THE

ELEMENT. CLEAN THE ELEMENT IN A

WELL VENTILATED AREA. ENSURE

THAT NO SPARKS OR FLAMES ARE

NEAR THE WORKING AREA, THIS

INCLUDES ANY APPLIANCE WITH A

PILOT LIGHT.

CAUTION: NEVER RUN THE ENGINE WITHOUT

THE AIR FILTER, SERIOUS DANGER

CAN RESULT.

Check the air cleaner daily or before starting the engine.

Check for and correct heavy buildup of dirt and debris along

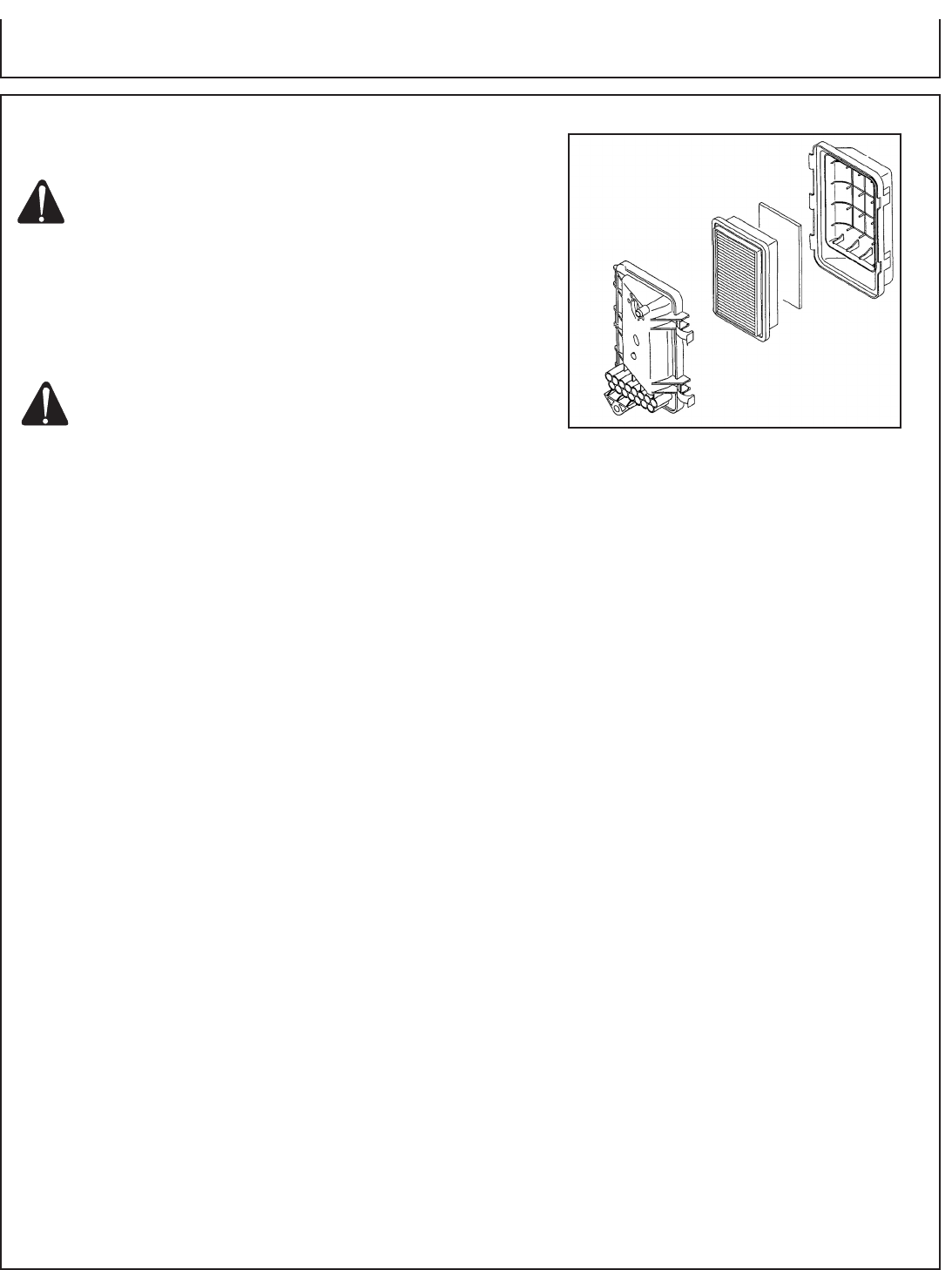

with loose or damaged components. (See Fig. 8)

1. Unsnap the air cleaner cover and remove the elements.

2. Clean the elements:

FOAM PRE-CLEANER ELEMENT: Wash the foam pre-

cleaner element in warm water with detergent. Rinse the

foam pre-cleaner element thoroughly until all traces of

detergent are eliminated. Squeeze out excess water, but do

not wring. Allow the foam pre-cleaner element to air dry.

Saturate the foam pre-cleaner element with new engine oil.

Squeeze out all excess oil. DO NOT put engine oil on the

foam damper.

NOTE: Clean the foam pre-cleaner element every 25 hours

of operation (more often under extremely dusty or

dirty condition)

PAPER AIR CLEANER ELEMENT: Do not wash the paper

element or use pressurized air, as this will damage the

element. Clean by gently tapping the element to remove

dust. Replace the element if damaged, bent or extremely

dirty. Handle new element carefully; do not use if the sealing

surfaces are bent or damaged.

NOTE: Replace the paper element every 100 hours (more

often under extremely dusty conditions.)

5. Reinstall the foam pre-cleaner element and the paper

air cleaner element. Close air cleaner cover and clasp

shut.

(Fig. 8)