Preparing the Generator

14 Operator’s Manual

ENGINE OIL

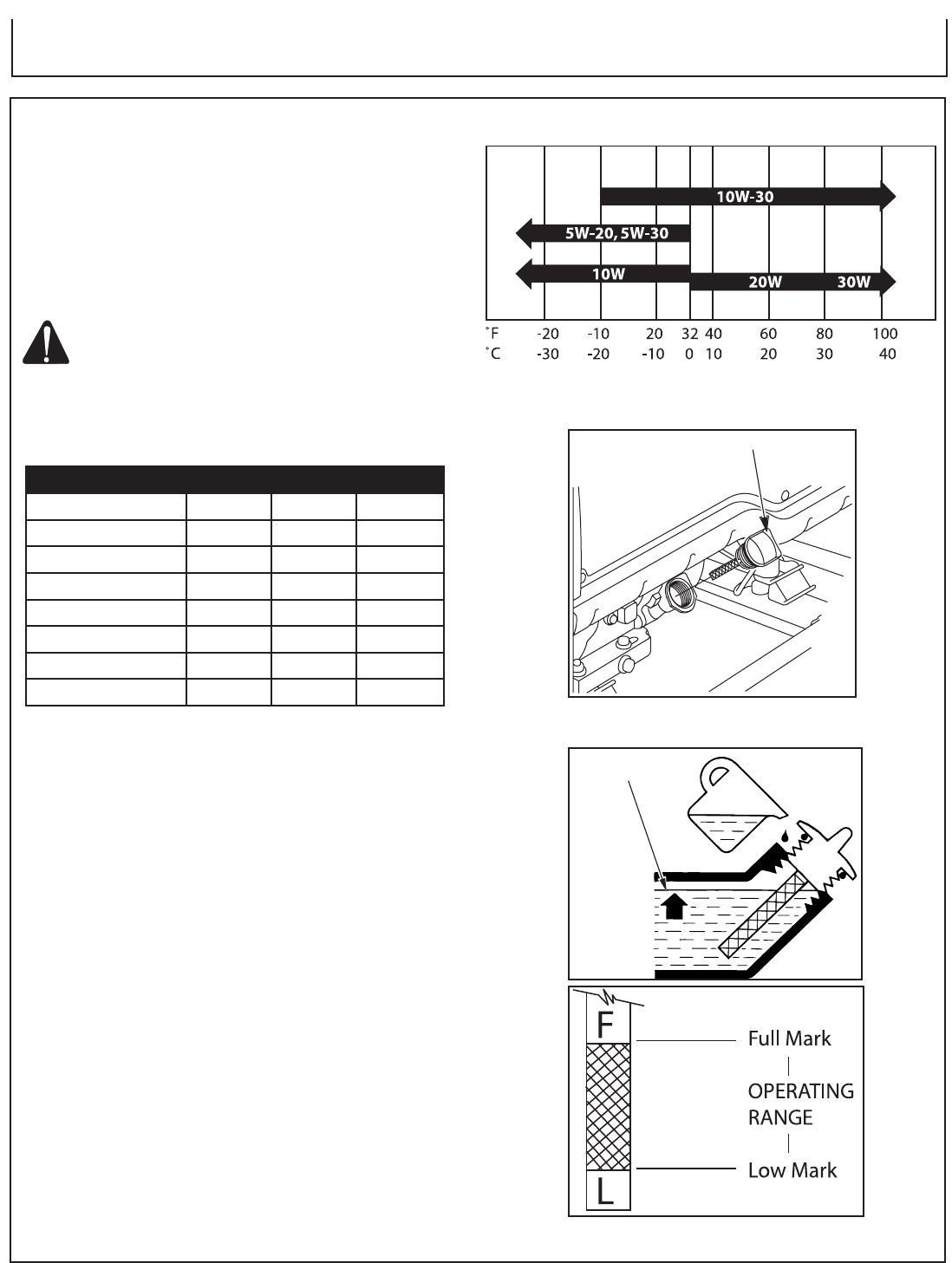

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

Use a high quality detergent oil with API classications of

SJ or higher.

Check oil level before each operation and ensure that it

is maintained.

CAUTION: THIS ENGINE CRANKCASE IS NOT

FILLED WITH OIL AT THE FACTORY, SO BE

SURE TO FILL IT BEFORE OPERATING THE

ENGINE.

ENGINE OIL CAPACITY

NOTE: These engines are equipped with a “Low Oil”

shut-off system for engine protection. If the

engine fails to start, check engine crankcase

for oil.

To ll with oil:

1. Level the engine to ensure accurate inspection and

to prevent overlling.

2. Unscrew the oil gauge (Fig. 1), wipe the dipstick dry.

Reinsert the oil gauge back into the oil ll gauge opening.

Remove the oil gauge and check the oil level.

3. The oil level should be between the full and low marks

on the dipstick. (Fig. 2)

NOTE: When checking the oil be sure the engine is

level.

4. Fill with oil as required through the oil ll gauge

opening.

5. Replace the oil gauge and screw in rmly.

6. Wipe up any spilled oil.

(Fig. 1)

(Fig. 2)

OIL GAUGE

UPPER LEVEL

TEMPERATURE CHART

MODEL # Liters Quart Ounces

AC-G6010H 0.6 0.63 20.3

AC-G6010HE 0.6 0.63 20.3

AC-G6010S 1.2 1.27 40.5

AC-G6010SE 1.2 1.27 40.5

AC-G7510H 1.1 1.16 37.2

AC-G7510HE 1.1 1.16 37.2

AC-G8010S 1.2 1.27 40.5

AC-G8010SE 1.2 1.27 40.5