14 4 1/4-Inch Disc Grinder Operator's Manual

OPERATION (CONTINUED):

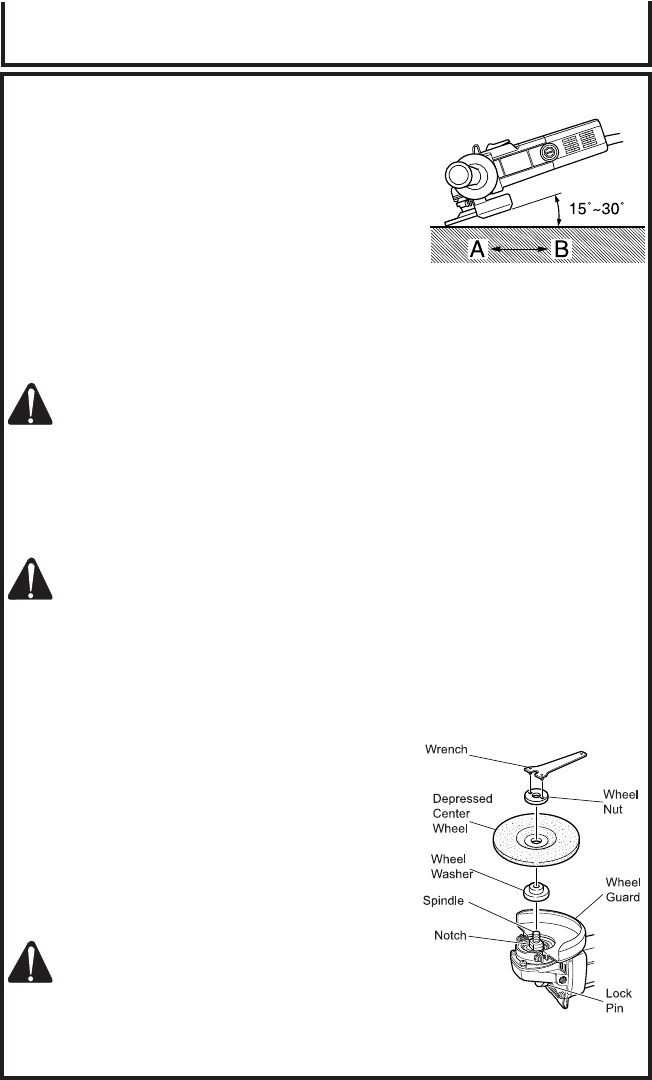

5. Move the grinder in the proper direction:

When using a new depressed center wheel in

direction A (Fig. 2), the wheel edge may cut into the

workpiece. In this case, grind in direction B (Fig. 2).

Once the wheel edge is worn, the workpiece can be

ground in both directions.

NOTE: The wheel provided (resinoid wheel) is rated as

Class A grain and # 36 grain size. It is most

suitable for heavy grinding of steel and other

types of materials.

6. Adjust operation to desired finish:

For a fine finish, decrease pressure by lifting slightly.

Grind slowly and at the appropriate speed.

CAUTION: THE REVOLVING DEPRESSED

CENTER WHEEL WILL CREATE

AIR TURBULENCE.

DO NO LAY THE GRINDER DOWN

IN AREAS OF DUST OR DIRT

UNTIL IT HAS COME TO A

COMPLETE STOP.

1. Assembling

a. Turn the disc grinder upsidedown so that the

spindle is facing upward.

b. Align the oval-shaped indentation of the wheel

washer with the notched part of the spindle,

then attach them.

c. Fit the protuberance of the depressed center

wheel onto the wheel washer.

d. Screw the wheel nut onto the spindle.

e. While pushing the lock pin with one hand, lock

the spindle by turning the depressed center

wheel slowly with the other hand. Tighten the

wheel nut by using the supplied wrench as

shown in Fig. 3.

CAUTION: TIGHTEN THE WHEEL NUT

SECURELY AND CONFIRM THAT

THE DEPRESSED CENTER WHEEL

DOES NOT WOBBLE.

2. Disassembling:

To remove the depressed center wheel, follow the

above-mentioned procedure in reverse order.

DEPRESSED CENTER WHEEL ASSEMBLY AND DISASSEMBLY:

WARNING: NEVER ATTEMPT TO ASSEMBLE OR DISASSEMBLE THE

DEPRESSED CENTER WHEEL WHILE THE GRINDER IS

CAPABLE OF BEING TURNED “ON”.

BE SURE POWER SWITCH IS IN THE “OFF” POSITION AND THE

ELECTRICAL CORD HAS BEEN DISCONNECTED FROM THE

RECEPTACLE.

Operation

(Fig. 2)

(Fig. 3)