EEDDGGEE GGRRIINNDDIINNGG

DDoo nnoott uussee eeddggee ggrriinnddiinngg wwhheeeellss ffoorr ccuutt--ooffff wwoorrkk,, ddeeeepp

ggrriinnddiinngg oorr ssuubbjjeecctt tthheemm ttoo aannyy ssiiddee pprreessssuurree

aass tthhiiss mmaayy lleeaadd ttoo bbrreeaakkaaggee

aanndd ppoossssiibbllee ppeerrssoonnaall iinnjjuurryy..

These wheels should be used for shallow cutting

and notching (less than 1/2" in depth). Keep the open side of the guard away

from the operator at all times.

Edge grinding should only be done with wheels specifically designed for this purpose.

RREEMMOOVVIINNGG GGUUAARRDD FFOORR SSAANNDDIINNGG OORR UUSSIINNGG FFLLAATT WWIIRREE BBRRUUSSHHEESS

• Set the Angle Grinder on a flat surface with the spindle facing up.

• Remove the inner and outer flanges, unscrew spring washer and remove

the guard.

• Store these parts carefully.

• Replace the guard after the job is finished.

AATTTTAACCHHIINNGG SSAANNDDIINNGG DDIISSCC

• To remove the guard, see instructions

given in the “Removing Guard for

Sanding or Using Flat Wire Brushes”

Section above.

• Set the inner flange and outer flange on

the spindle.

• Push in the spindle lock button. Turn the

spindle until it locks into place.

• Once the spindle is locked, tighten the

sanding disc by hand.

OOPPEERRAATTIINNGG TTHHEE AANNGGLLEE GGRRIINNDDEERR

AAllwwaayyss uunnpplluugg tthhee ttooooll bbeeffoorree aatttteemmppttiinngg ttoo cchhaannggee tthhee

gguuaarrdd oorr aacccceessssoorriieess..

WARNING

12

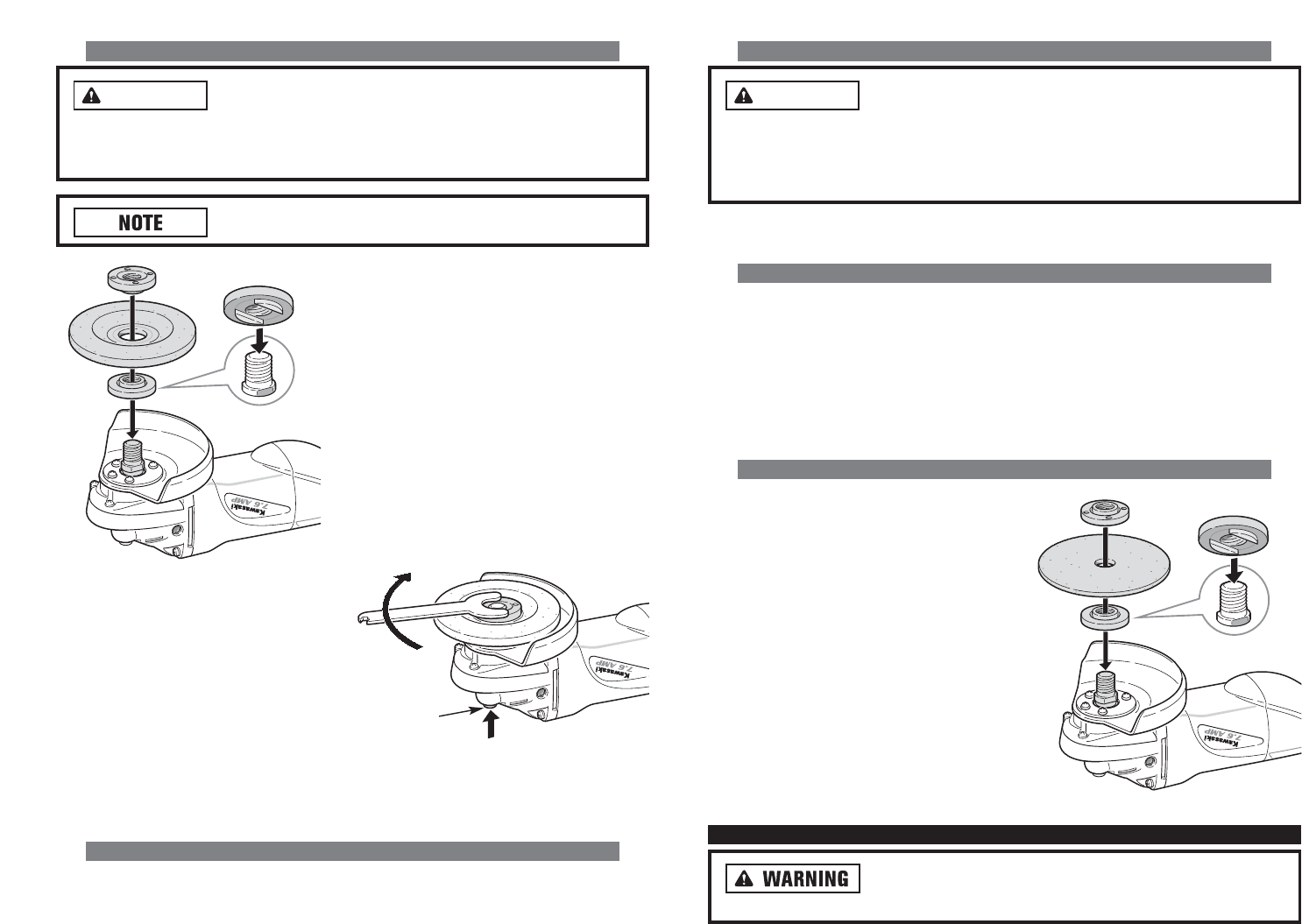

AATTTTAACCHHIINNGG WWHHEEEELLSS WWIITTHH DDEEPPRREESSSSEEDD CCEENNTTEERRSS

AAllwwaayyss cchheecckk tthhee ttooooll wwaarrnniinngg llaabbeell ffoorr tthhee rreeccoommmmeenndd--

eedd ssppeeeedd rraattiinngg oonn aacccceessssoorriieess..

Never run a wheel or brush over the rated

speed. Accessories exceeding the recommended speed may fly apart and cause

serious personal injury.

HHuubbbbeedd wwhheeeel

lss ddoo nnoott rreeqquuiirree mmoouunnttiinngg ffllaannggeess..

• Press the spindle lock firm and

insure there is no movement in the

spindle. Then while the spindle lock

is depressed tighten the locking nut

in a clockwise direction using the

pin spanner.

• Allow the Angle Grinder to run in

idle for at least a minute with the

grinding or cutting disc correctly

assembled.

AATTTTAACCHHIINNGG WWIIRREE BBRRUUSSHHEESS

Wire cup brushes, not included, can be screwed directly on the spindle. No flanges are

necessary.

WARNING

11

SPINDLE

LOCK

BUTTON

• Place the backing washer over the

spindle making sure the fit is tight.

• Place the grinding or cutting disc on the

top of the backing washer ensuring the

bore fits into the step of the flange.

• Mount the concave recess side of the

locking nut over the spindle.