THUMB

SCREW

GUN

A-5

INSTALLATION

A-5

PRESSURE ARM ADJUSTMENT

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the weld-

ing power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several sec-

onds after the gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform mainte-

nance work.

------------------------------------------------------------------------

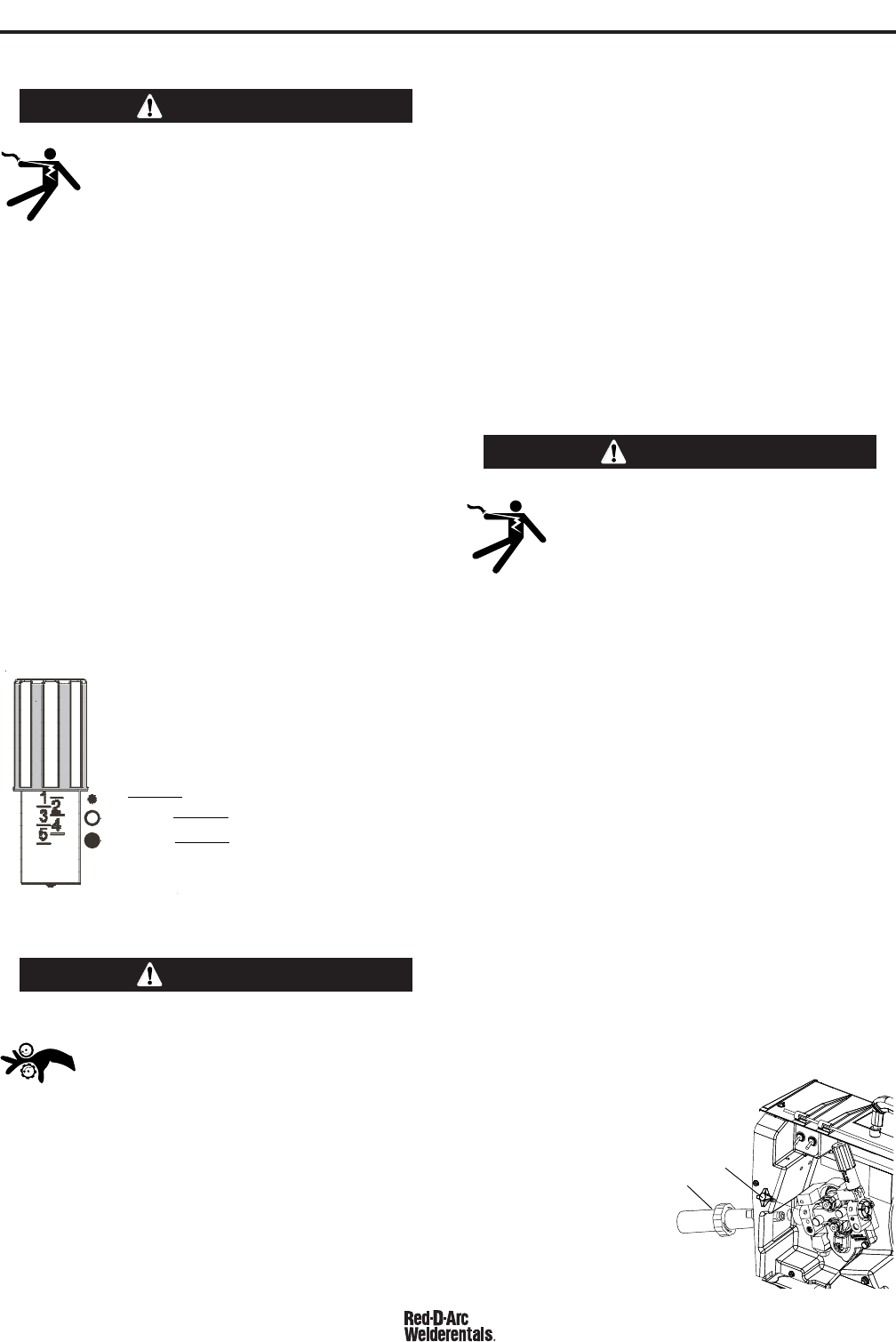

The pressure arm controls the amount of force the

drive rolls exert on the wire. Proper adjustment of the

pressure arm gives the best welding performance.

Set the pressure arm as follows:

(See Figure A.3)

Aluminum wires between 1 and 3

Cored wires between 3 and 4

Steel, Stainless wires between 4 and 6

LOADING SPOOLS OF WIRE

• Keep hands, hair, clothing and tools

away from rotating equipment.

• Do not wear gloves when threading wire

or changing wire spool.

• Only qualified personnel should install,

use or service this equipment.

------------------------------------------------------------------------

Loading 10 to 15 lb. (4.5 – 6.8kg) Spools.

A K468 spindle adapter is required for loading 2"

(51mm) wide spools on 2" (51mm) spindles. Use a

K468 spindle adapter for loading 2-1/2" (64mm) wide

spools.

1. Squeeze the release bar on the retaining collar and

remove it from the spindle.

2. Place the spindle adapter on the spindle, aligning

the spindle brake pin with the hole in the adapter.

3. Place the spool on the spindle and align the

adapter brake tab with one of the holes in the back

side of the spool. An indicator mark on the end of

the spindle shows the orientation of the brake tab.

Be certain the wire feeds off of the spool in the

proper direction.

4. Re-install the retaining collar. Make sure that the

release bar snaps out and that the retaining collar

fully engages the groove on the spindle.

GUN CONNECTION

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the weld-

ing power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several sec-

onds after the gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform mainte-

nance work.

------------------------------------------------------------------------

The LN25 PRO EXTREME comes with a K1500-2 gun

adapter installed. (See Figure A.4)

To install a gun,

1. Turn power OFF.

2. Remove the thumb screw.

3. Push the gun the completely into the gun bushing.

4. Secure the gun in place with the thumb screw.

5. Connect the trigger cable from the gun to the trigger

connector on the front of the feeder.

Note: Not all gun bushings require the use of the

thumb screw.

WARNING

WARNING

6

Al

Fe, CrNi

Fe, CrNi

ALUMINUM WIRES

CORED WIRES

STEEL, STAINLESS WIRES

FIGURE A.3

WARNING

FIGURE A.4

LN-25 PRO EXTREME