POWER MIG

®

215XT

www.lincolnelectric.com

[2]

A CLOSER LOOK

PROCESS CAPABILITIES

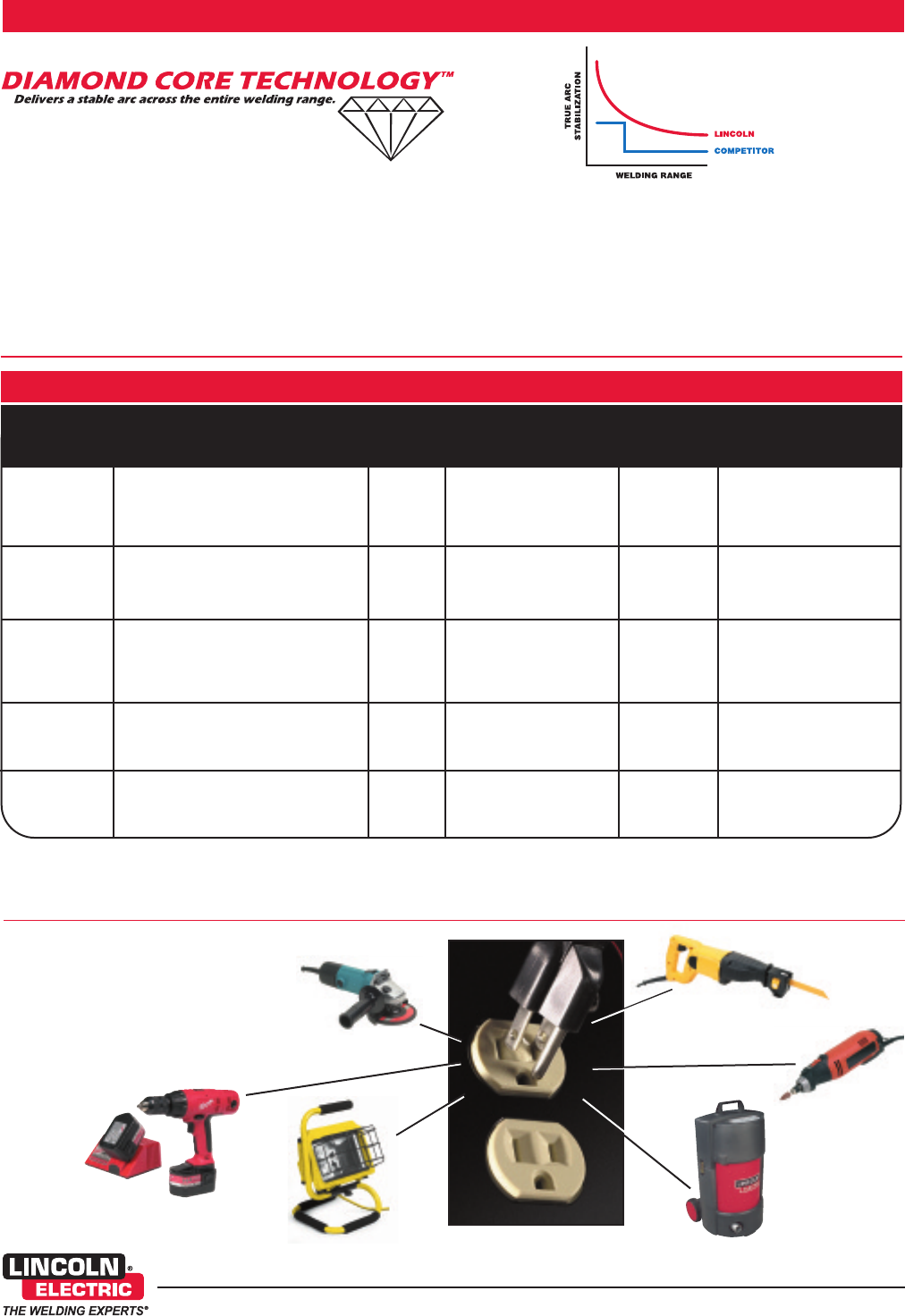

E

lectrode Electrode Shielding Minimum Maximum

Process Wire Polarity Gas Thickness Thickness

(1)

M

IG .025, .030, .035, .045"

M

ild Steel (0.6, 0.8, 0.9, 1.2 mm) DC+ 100% CO

2

o

r Ar/CO

2

B

lend 24 ga. (.024") 5/16" (.312")

SuperArc

®

L50, L-56 (0.6 mm) (7.9 mm)

SuperGlide

®

S-3, S-6

MIG .030, .035, .045" DC+ Ar/CO

2

Blend 20 ga. (.036") 1/4" (.250")

Stainless (0.8, 0.9, 1.2 mm) or (Tri-Mix) (0.9 mm) (6.4 mm)

Blue Max

®

308LSi, 309LSi, 316LSi 90% He, 7-8% Ar/Balance C0

2

MIG 3/64" 1/16" (.063") 1/4" (.250")

Aluminum

(3)

(0.2 mm) DC+ 100% Argon (1.6 mm) (6.4 mm)

SuperGlaze

®

4043 and 5356

Flux-Cored, .035, .045" 100% CO

2

or Ar/CO

2

Blend 12 ga. (.109") 1/2" (.500")

Gas-Shielded (0.9, 1.2 mm) DC+ (2.7 mm) (12.7 mm)

Mild Steel Outershield

®

71M and MC-710

Flux-Cored, .035, .045" 18 ga. (.050") 1/2" (.500")

Self-Shielded (0.9, 1.2 mm) DC- — (1.2 mm) (12.7 mm)

Mild Steel Innershield

®

NR

®

-211-MP

(2)

and NR

®

-212

(1)

Lincoln Electric recommends multiple pass welds on 1/2" (12.7 mm) material. Consult the appropriate application procedures and guidelines for selecting the correct wire size,

gas type and number of passes.

(2)

.035" and .045" (0.9 and 1.2 mm) NR

®

-211-MP is only recommended up to 5/16" (7.9 mm) thick material.

(3)

For .035" (0.9 mm) and 4043 aluminum wire, the spool gun is recommended for best feeding results.

FEATURES

Energize Your Shop

The POWER MIG

®

215XT is the only

machine in its class to feature a 115 volt

auxiliary power receptacle which allows

you to power grinders, lights, cordless

tool chargers or any other power tools.

PERFORMANCE

Grinders

Battery Chargers

for Cordless Tools

Work Lights

Welding Fume

Extraction

Rotary Tools

Saws

What Is It?

Diamond Core Technology

™

is a patented innovative

choke design that filters the welding arc. It provides

dynamic arc filtering across the entire welding amp

rage. Other arc stabilization methods are “fixed” –

or only working at certain amperages – resulting in

harsh arc characteristic changes over the welding

range.

Results:

• Great starts and low spatter.

• A wide sweet spot for optimal

arc performance.

Great For:

• Steel, stainless and aluminum.

• Out-of-position work.

• Long arc applications.

• Weaving techniques.