A CLOSER LOOK

Precision TIG

®

275

www.lincolnelectric.com

[2]

What Is It?

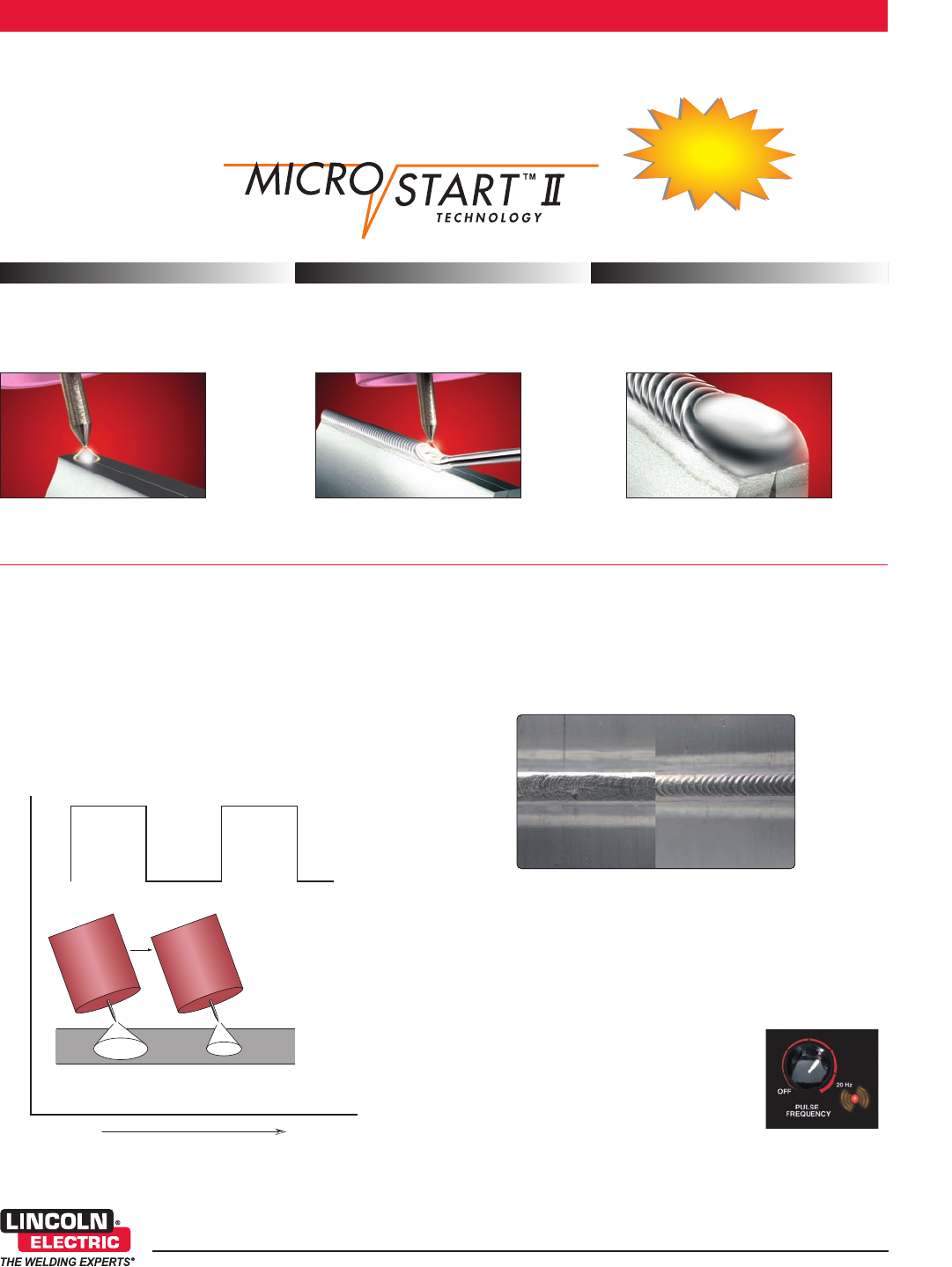

Pulse welding systems vary weld current between peak (high heat)

and background current (low heat) levels. Adjusting the pulse fre-

quency controls the level of heat input applied to the weld relative

to the weld travel speed.

Results

Better control of heat input in the weld, resulting in:

• Reduced warping and burnthrough on thin materials.

• Smaller heat-affected zone – good for thin material.

• Smaller bead profile without compromising proper penetration.

Great For

• Thin materials – Faster pulse settings help to narrow the bead

profile and minimize the heat-affected zone and resulting warping

or burnthrough.

• Consistent appearance – Slower pulse settings aid in timing the

application of filler metal to produce the consistent stacked bead

appearance associated with high quality TIG

welding.

• Maintaining a steady welding rhythm.

Easy “Set It/See It” Operation:

• Flashing indicator light lets you see the

pulse rate before you strike an arc.

Welding Current

Peak

Background

PULSE FREQUENCY:

Number of Pulses Per Second

Time

High Heat

(Peak)

Low Heat

(Background)

Pulsed TIG Weld

(at 60 amps)

Standard TIG Weld

(at 60 amps)

Smaller Heat

Affected Zone

Smaller Heat

Affected Zone

Smaller Bead Profile

Smaller Bead Profile

Micro-Start II™ Technology aids arc stability

THROUGHOUT THE WELD CYCLE –

even at the lowest amperage!

Micro-Start II™ Technology

controlled ramp down helps precisely fill

the weld crater for quality results.

Micro-Start II™ Technology minimizes high

frequency and ‘hot starts’ to deliver soft arc starts

without arc wandering for AC and DC welding.

ARC PERFORMANCE

Micro-Start II™ Technology — More than just a starting aid.

Better control for starting, arc stability and crater fill.

Great Starting Stable, Focused Arc Precise Crater Fill

“Set It/See It” Pulse Control — Make attractive and consistent welds!

NOW

INCLUDES

AC

forALUMINUM

WELDING

AC