Process Electrode Wire/Stick Electrode Polarity Shielding Gas

Mild Steel FCAW .045" (1.2mm) UltraCore Positive

CO

2

or Blended

Gas-Shielded Wire 71A75 Dual (DC+)

Mild Steel .045" (1.2mm) Metalshield MC-6 Positive

Blended

Composite MIG (DC+)

Mild Steel FCAW 5/64" (2.0mm) Innershield

®

Positive None Required

Self-Shielded Wire NS-3M Only (DC+) (Self-Shielded)

Hardfacing

.045 - 5/64" (1.2-2.0mm) Lincore

®

Positive

As Required

Self and Gas-Shielded (DC+)

Steel or Stainless 3/32" - 1/4" (2.4-6.4mm) Excalibur

®

7018 Positive None Required

SMAW, Stick and Fleetweld

®

6010 (DC+) (Stick Electrode)

Mild Steel or .025" - .052" (0.6-1.3mm) Super Arc

TM

Positive CO

2

or CO

2

Ar Blended

Stainless MIG L-50 and L-56 and Blue Max

TM

(DC+) or Tri Mix

Aluminum 3/64" - 1/16" (1.2-1.6mm) SuperGlaze

TM

Positive

100% Argon

MIG 4043 and 5356 (DC+)

Air Carbon

5/32" - 5/16" (4.0-8.0mm)

Positive

Compressed Air

Arc Gouging (DC+)

[4]

www.lincolnelectric.com

3

700 AMP ARC GOUGING TORCH

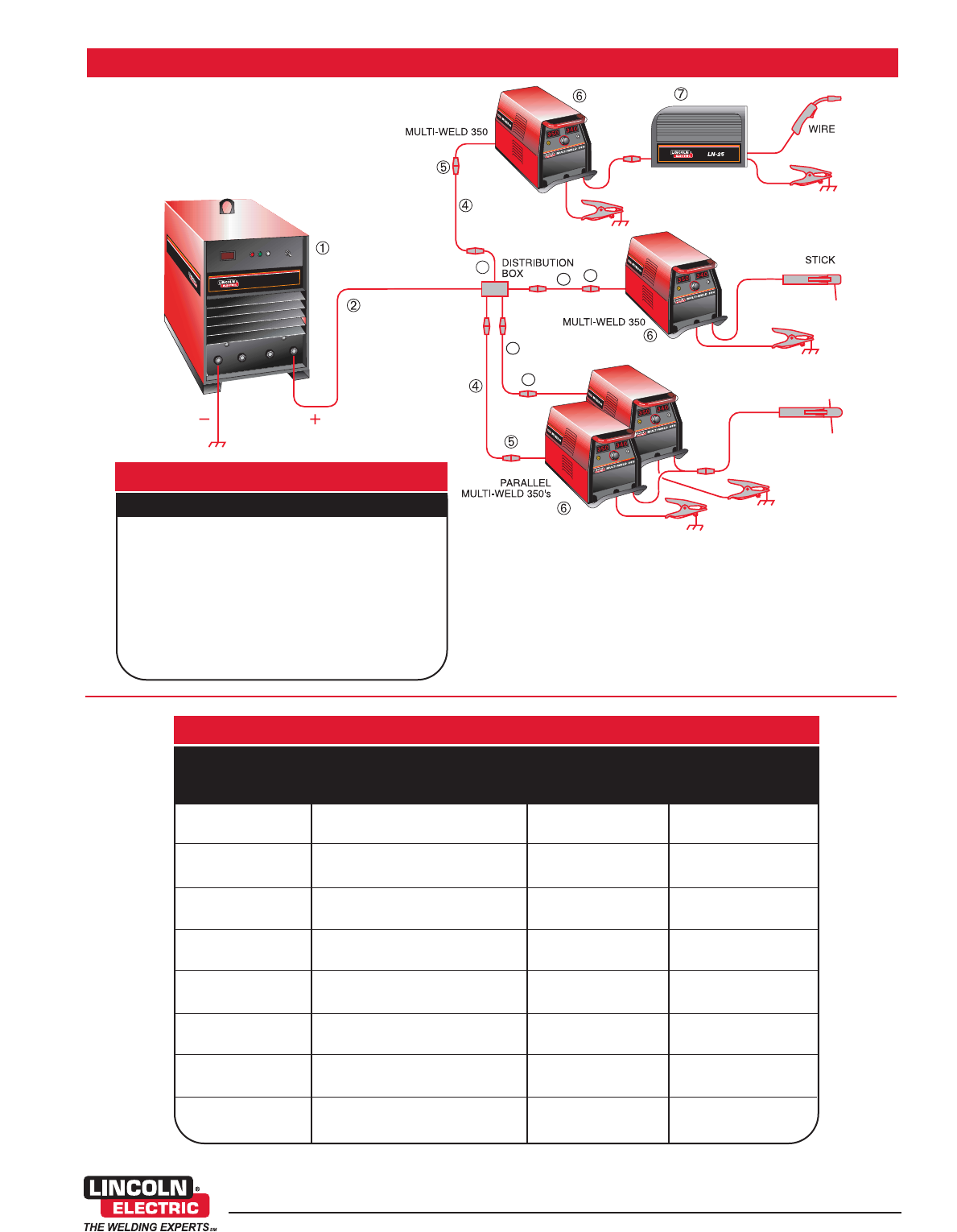

1. Power Source

2. Input Cable, 4/0 - 100 ft. .......................................... L-4/0-100

3. Distribution Box ........................................................ K1736-1

4. Input Cable, 1/0 - 25 ft............................................... L-1/0-25

5. Welding Cable Connectors

Twist-Mate Male Connector.................................... K852-70

Twist-Mate Female Connector................................ K1759-70

6. Multi-Weld 350s ........................................................ K1735-1

7. LN-25 ........................................................................ K449

Multi-Weld 350

[4]

PROCESS CAPABILITIES

A CLOSER LOOK

SYSTEM SELECTION

SYSTEM SELECTION

Product Product Number

POWER SOURCE WITH 72V

MINIMUM OCV

(OPEN CIRCUIT VOLTAGE)

ACROSS THE ARC

WIRE FEEDER

(DC+ ONLY)

4

5

5

4