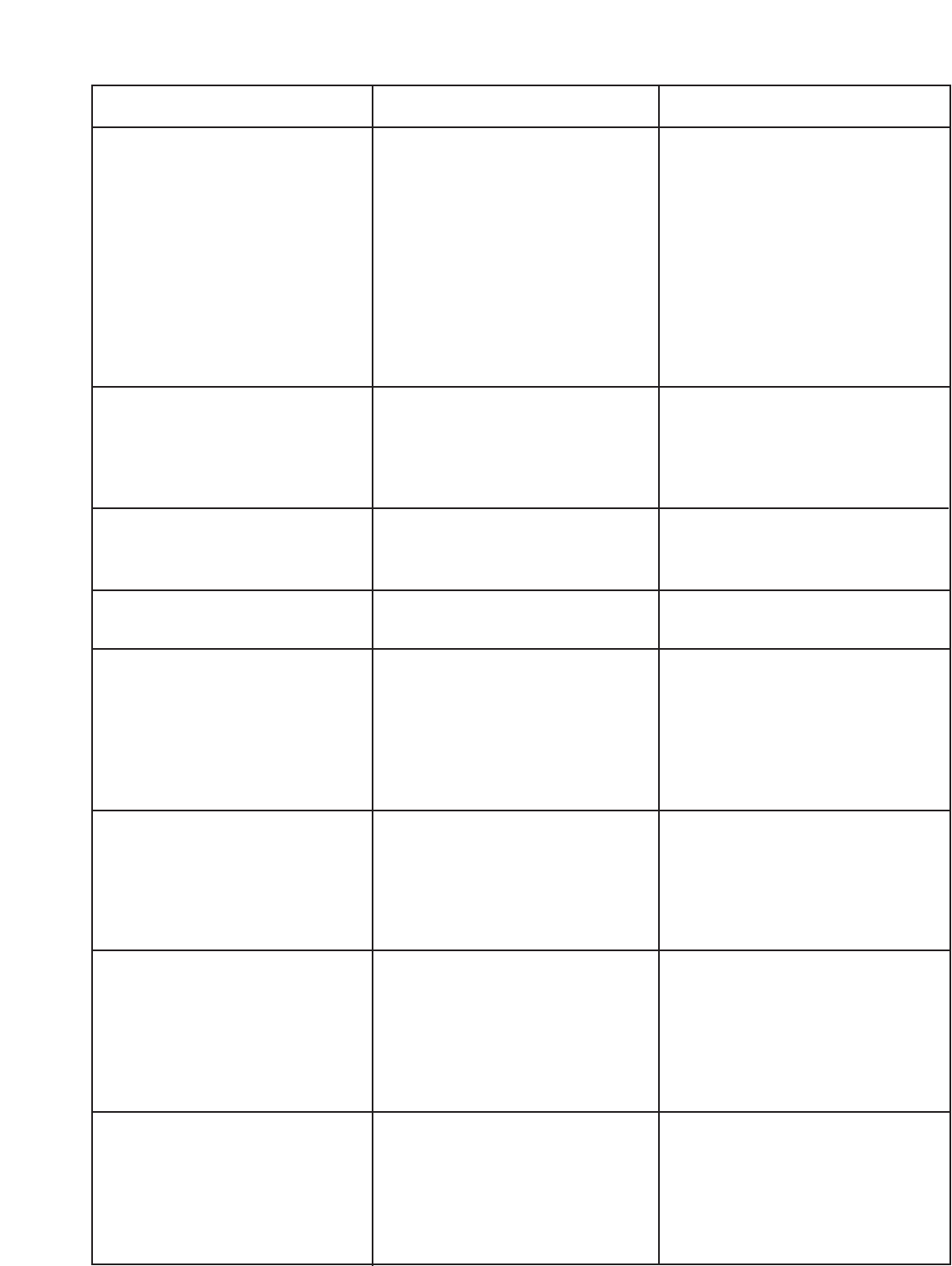

– 35 –

PROBLEM

20. Wire feed speed is consistent

and adjustable, but operates at the

wrong speed.

21. Display shows any of the

following:

HI

- - -

HXX

Er

EXX

EP

uP

POSSIBLE CAUSE

a.Defective gearbox ratio sensing

or control board.

a. Voltmeter function is selected

and arc voltage is > 80V DC.

a. Run-In speed is selected but is

disabled.

a. See problem 5 or see section on

Safety Precautions.

a. EEPROM error.

a. Where XX is a number from

1-10. System error.

a. EPROM checksum error.

a. Microprocessor RAM error.

WHATTODO

a. Remove control board plug from

J5. Check that if you have a high

speed Wire Feed Unit that you have

continuity between plug P5 pins 4

and 6. Likewise if you have a

standard speed Wire Feed Unit you

should not have continuity between

P5 pins 4 and 6. If the continuity test

fails, refer to wiring diagram and

correct the problem in the J13 to J5

jumper sensing system. Otherwise

replace control board.

a. Normal operation. Voltmeter only

reads 0-80V DC.

a. Run-In speed is now = weld

speed. To re-enable Run-In speed

simply press the increase arrow key.

a. XX indicates time in seconds

before unit will automatically reset.

a. Parameter recalled at power-up

was out of range. Press any key

to reset. Check all settings before

proceeding to weld. If this

condition persists then replace

control PC board. (See Procedure

for Replacing PC boards.)

a. Turn off power to feeder. Wait 5

seconds. Turn power back on. If

EXX is displayed again then

replace control PC board. (See

Procedure for Replacing PC

boards.)

a. Turn off power to feeder. Wait 5

seconds. Turn power back on. If

EP is displayed again then replace

EPROM assembly. If problem still

persists then replace Control PC

board . (See Procedure for

Replacing PC boards.)

a. Turn off power to feeder. Wait 5

seconds. Turn power back on. If

uP is displayed again, then

replace control PC board. (See

Procedure for Replacing PC

boards.)

PROBLEMS