THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

CUSTOME R ASSISTANCE POL ICY

Thebusiness ofTheLincoln Electric Company ismanufacturingand selling highqualitywelding equipment, consumables, andcuttingequipment. Ourchallengeis tomeetthe

needsof ourcustomersand to exceed theirexpectations.On occasion, purchasers mayaskLincoln Electric for adviceor information abouttheiruse of ourproducts.Werespond

toour customers basedonthe best informationinour possession atthattime. Lincoln Electric isnotin apositiontowarrant orguaranteesuch advice, andassumesno liability,

withrespect to such informationoradvice. Weexpresslydisclaim anywarrantyof anykind,includingany warrantyoffitness foranycustomer’s particularpurpose,with respectto

suchinformation or advice.Asa matter ofpracticalconsideration, wealsocannot assumeanyresponsibilityfor updating orcorrectinganysuch information oradviceonce ithas

beengiven, nordoesthe provision ofinformationoradvice create, expand oralterany warrantywithrespectto thesaleofour products.

LincolnElectric isaresponsivemanufacturer, but the selectionanduse ofspecificproductssold by LincolnElectricis solely withinthecontrolof, andremainsthesole responsibility

ofthe customer.Manyvariables beyond thecontrolofLincoln Electricaffect theresults obtainedinapplying these typesoffabrication methods andservicerequirements.

Subjectto Change —Thisinformation isaccurateto the best ofourknowledge atthetimeof printing.Pleaserefer towww.lincolnelectric.comfor anyupdatedinformation.

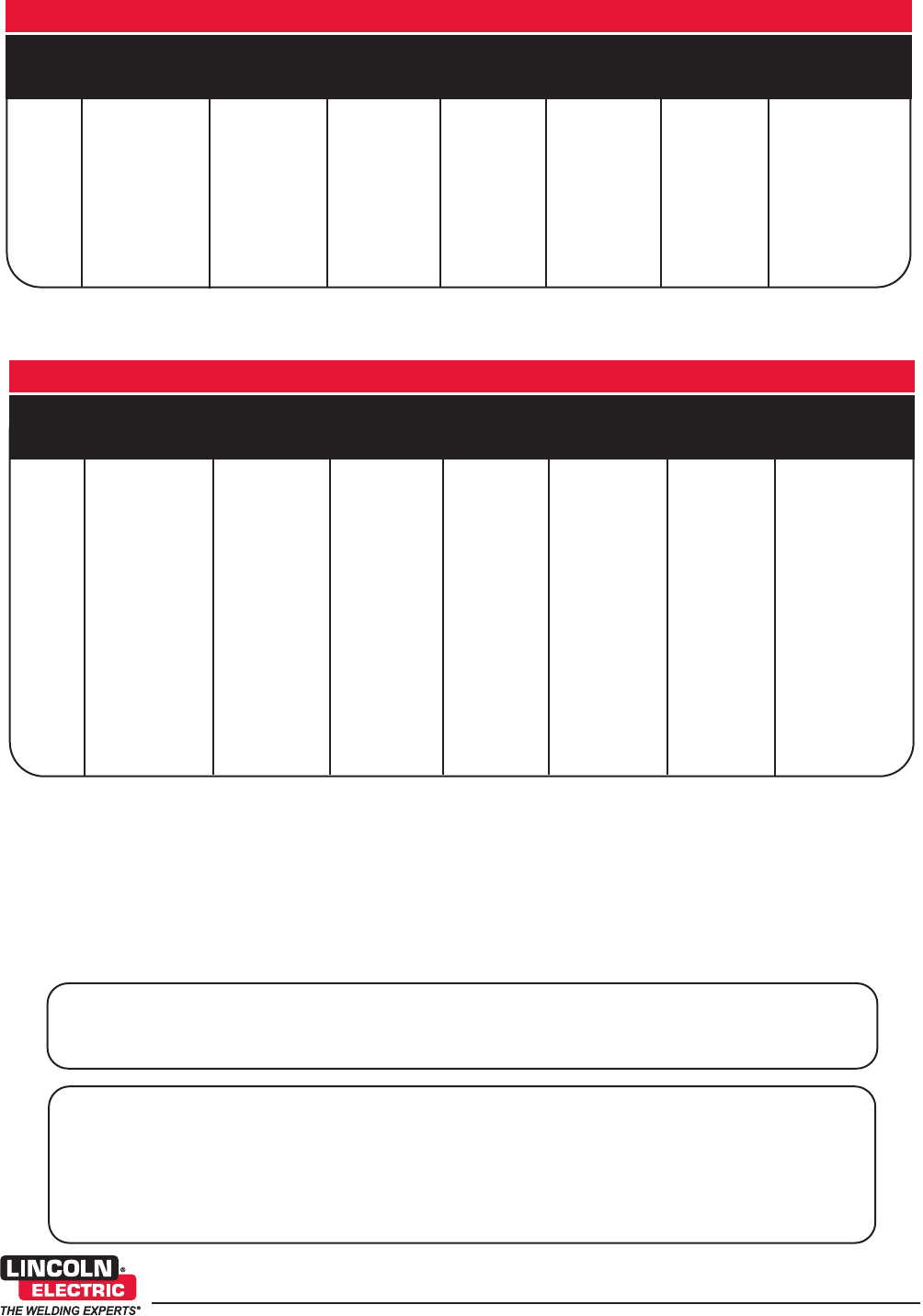

TEST RE SULTS

Testresultsfor mechanicalproperties,deposit orelectrode compositionanddiffusible hydrogenlevels were obtainedfroma weld produced and tested according toprescribed

standards,and should not beassumedto betheexpected results in aparticularapplication orweldment.Actual resultswill varydependingon manyfactors,including, butnot

limitedto, weldprocedure,platechemistry andtemperature,weldmentdesign andfabrication methods.Users are cautioned toconfirmby qualificationtesting, orother

appropriatemeans, the suitability ofanywelding consumable andprocedurebeforeuse intheintended application.

Yield Tensile

S

trength Strength Elongation Charpy V-Notch AWS Classper

Wire Weld Condition ksi (MPa) ksi (MPa) (%) ft•lbf (J) @ ºF (ºC) AWS A5.17

L

-50 As-welded 62 (430) 78 (540) 31 90 (122) -80º (-62º) F7A8-EM13K-H4

L

-50 Stress-relieved 53(370) 74 (510) 32 138 (187) -80º (-62º) F6P8-EM13K-H4

L-56 As-welded 74 (510) 88 (610) 29 52 (71) -80º(-62º) F7A8-EH11K-H4

L

-56 Stress-relieved 59(410) 79 (540) 32 87 (118) -80º (-62º) F7P8-EH11K-H4

L

-61 As-welded 61 (420) 75 (520) 31 89 (120) -60º (-51º) F7A6-EM12K-H4

L-S3 As-welded 65 (450) 82 (570) 31 106 (144) -80º (-62º) F7A8-EH12K-H4

L-S3 Stress-relieved 54(370) 74 (510) 33 122 (165) -80º (-62º) F6P8-EH12K-H4

L

A-71 As-welded 75 (520) 89 (610) 28 50 (68) -60º(-51º) F7A6-EM14K-H4

L

A-71 Stress-relieved 60(410) 78 (540) 32 99 (134) -80º (-62º) F7P8-EM14K-H4

MECHANICAL PROPERTIES – Welded per AWS A5.17 (Carbon Steel Electrodes)

MECHANICAL PROPERTIES – Welded per AWS A5.23 (Low Alloy Electrodes)

Y

ield Tensile

Strength Strength Elongation Charpy V-Notch AWS Classper

Wire Weld Condition ksi (MPa) ksi (MPa) (%) ft•lbf (J) @ ºF (ºC) AWS A5.23

L

-70 As-welded 74 (510) 87 (600) 29 45 (61) -40º (-40º) F7A4-EA1-A2-H4

L-70 Stress-relieved 69(470) 83 (570) 31 54 (73) -40º (-40º) F7P4-EA1-A2-H4

LA-75 As-welded 68 (470) 84 (580) 31 90 (122) -80º (-62º) F7A8-ENi1K-Ni1-H4

L

A-82 As-welded 99 (680) 113 (780) 23 52 (70) -80º (-62º) F10A8-EF2-F2-H4

L

A-82 Stress-relieved 87(600) 102 (700) 26 58 (79) -60º (-51º) F9P6-EF2-F2-H4

LA-84 As-welded 92 (630) 105 (720) 23 57 (77) -80º (-62º) F9A8-EF3-F3-H4

LA-84 Stress-relieved 84(580) 98 (670) 26 25 (33) -60º (-51º) F8P6-EF3-F3-H4

LA-85 As-welded 78 (540) 92 (630) 26 58 (79) -60º (-51º) F8A6-ENi5-Ni5-H4

LA-85 Stress-relieved 73(500) 87 (600) 29 34 (46) -60º (-51º) F7P6-ENi5-Ni5-H4

LA-90 As-welded 89 (610) 102 (700) 26 41 (56) -60º (-51º) F9A6-EA3K-A3-H4

LA-100 As-welded 98 (680) 109 (750) 24 35 (48) -40º (-40º) F10A4-EM2-M2-H4

LA-100 Stress-relieved 99(680) 110 (760) 25 38 (52) -20º (-29º) F10P2-EM2-M2-H4

LAC-B2 Stress-relieved 76(520) 90 (620) 24 60 (81) -40º (-40º) F8P4-ECB2-B2-H8

LAC-M2 As-welded 116 (800) 130 (890) 21 40 (55) -80º (-62º) F12A8-ECG-G-H8

LAC-Ni2 As-welded 78 (540) 92 (630) 20 42 (57) -80º (-62º) F8A8-ECNi2-Ni2-H8

LAC-Ni2 Stress-relieved 70(480) 84 (580) 27 47(64) -100º (-73º) F7P10-ECNi2-Ni2-H8